Prothioconazole dispersible oil suspension agent

A technology of prothioconazole and dispersing oil, applied in the directions of fungicides, biocides, biocides, etc., can solve problems such as no environmental risks, and achieve the effects of reducing the loss of effective components, improving dispersibility, and strong adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

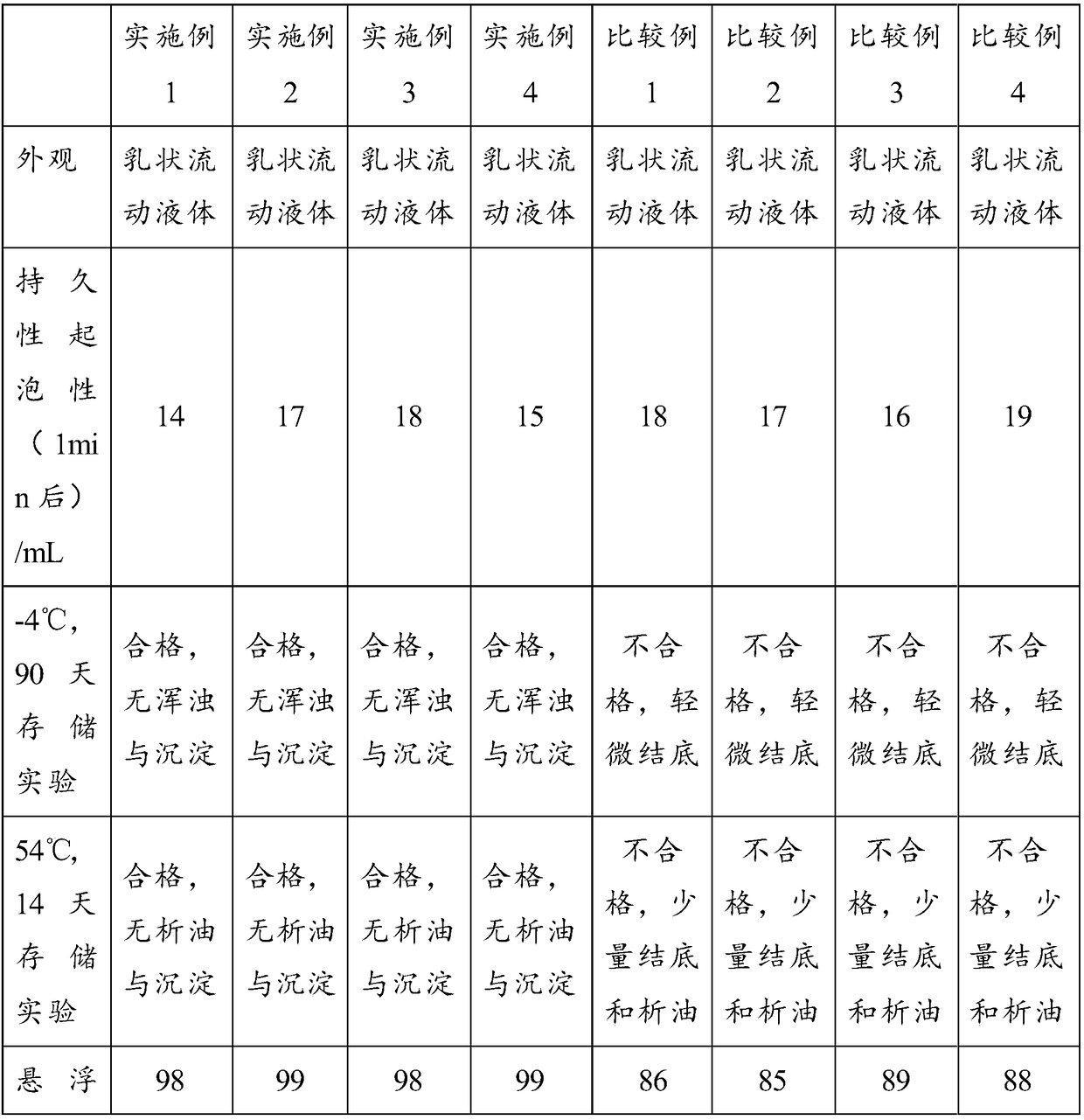

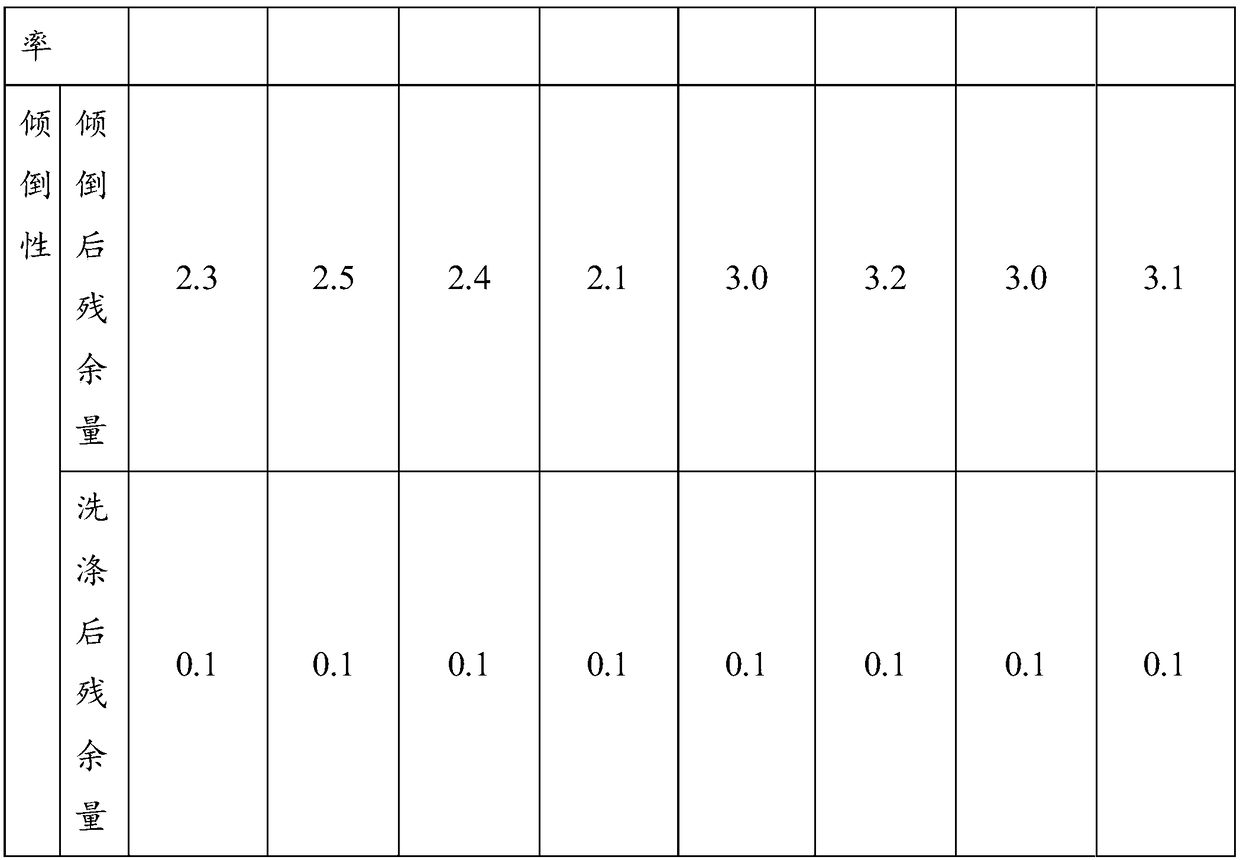

Examples

Embodiment 1

[0033] Prothioconazole 10kg, triglyceride polyoxyethylene ether 8kg, sodium polyacrylate 5kg, organic bentonite 0.5kg, meteorological silica 1.5kg, silicone 0.5kg, 10kg modified soybean oil, 54.5kg oleic acid formazan Esters, 10kg mineral oil.

[0034] Preparation:

[0035] 1) Add prothioconazole original drug, glyceryl triglyceride polyoxyethylene ether, sodium polyacrylate, organic silicon, organic bentonite, meteorological silica, modified soybean oil, methyl oleate, mineral oil, under high-shear stirring, to fully mix the materials evenly, put the mixed materials into a sand mill for grinding, and sand mill for 1-2 hours to obtain a prothioconazole dispersible oil suspension.

Embodiment 2

[0037] Prothioconazole 16kg, dibenzyl biphenyl polyoxyethylene ether 8kg, sodium polyacrylate 5kg, organobentonite 0.6kg, meteorological silica 1.8kg, silicone 0.5kg, modified soybean oil 11kg, oleic acid 46.1kg Methyl ester and 11kg mineral oil.

[0038] Preparation:

[0039] 1) Add prothioconazole original drug, dibenzyl biphenyl polyoxyethylene ether, sodium polyacrylate, organic silicon, organic bentonite, meteorological silica, modified soybean oil, methyl oleate, Mineral oil, under high-shear stirring, to fully mix the materials evenly, put the mixed materials into a sand mill for grinding, and sand mill for 1 to 2 hours to obtain a prothioconazole dispersible oil suspension.

Embodiment 3

[0041] Prothioconazole 20kg, styrylphenyl polyoxyethylene ether 8kg, sodium polyacrylate 5kg, organic bentonite 0.5kg, meteorological silica 1.5kg, organic silicon 0.5kg, 10kg modified soybean oil, 44.5kg oleic acid formazan Esters, 10kg mineral oil.

[0042] Preparation:

[0043] 1) Add prothioconazole original drug, styrylphenyl polyoxyethylene ether, sodium polyacrylate, organic silicon, organic bentonite, meteorological silica and modified soybean oil, methyl oleate, mineral oil, under high-shear stirring, to fully mix the materials evenly, put the mixed materials into a sand mill for grinding, and sand mill for 1-2 hours to obtain a prothioconazole dispersible oil suspension.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com