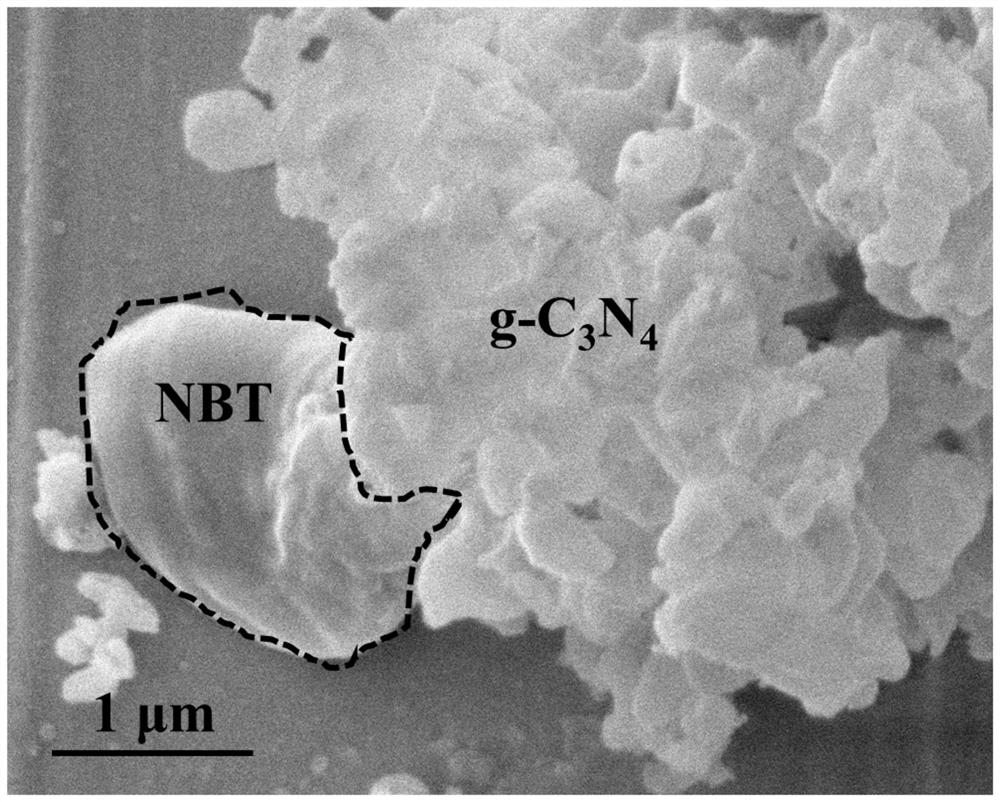

Sodium bismuth titanate/graphite phase carbon nitride heterojunction piezoelectric photocatalyst and preparation method thereof

A graphite phase carbon nitride, sodium bismuth titanate technology, applied in catalyst activation/preparation, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Photocatalyst preparation is complicated and other problems, to achieve the effect of low cost, excellent photocatalytic performance, and improved specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of sodium bismuth titanate / graphite phase carbon nitride heterojunction piezoelectric photocatalyst, comprising the following steps:

[0048] Step 1, synthesis of NBT nanoparticles:

[0049] 5.6ml of tetra-n-butyl titanate, 3.88g of bismuth nitrate pentahydrate and 14.4g of sodium hydroxide were dispersed in 80ml of deionized water, and stirred at room temperature for 2 hours to obtain a mixed solution. Use a measuring cylinder to measure 60ml of the obtained mixed solution, pour it into a 100ml Teflon lining, put the lining into the matching stainless steel outer lining, place the whole in a well-type furnace, and raise the temperature to 160°C and keep at this temperature for 24h. Pour the final solution and the precipitate into a centrifuge tube, wash with deionized and absolute ethanol three times, centrifuge at 10000r / min for 5min, pour off the unreacted precursor solution, and place the precipitate in an oven Dry at 80°C for 12h to obtain NB...

Embodiment 2

[0060] A preparation method of sodium bismuth titanate / graphite phase carbon nitride heterojunction piezoelectric photocatalyst, comprising the following steps:

[0061] Step 1, synthesis of NBT nanoparticles:

[0062] 5.6ml of tetra-n-butyl titanate, 3.88g of bismuth nitrate pentahydrate and 14.4g of sodium hydroxide were dispersed in 80ml of deionized water, and stirred at room temperature for 2 hours to obtain a mixed solution. Use a measuring cylinder to measure 60ml of the obtained mixed solution, pour it into a 100ml Teflon lining, put the lining into the matching stainless steel outer lining, place the whole in a well-type furnace, and raise the temperature to 180°C and keep at this temperature for 18h. Pour the final solution and the precipitate into a centrifuge tube, wash with deionized and absolute ethanol three times, centrifuge at 10000r / min for 5min, pour off the unreacted precursor solution, and place the precipitate in an oven Dry at 80°C for 12h to obtain NB...

Embodiment 3

[0068] A preparation method of sodium bismuth titanate / graphite phase carbon nitride heterojunction piezoelectric photocatalyst, comprising the following steps:

[0069] Step 1, synthesis of NBT nanoparticles:

[0070] 5.6ml of tetra-n-butyl titanate, 3.88g of bismuth nitrate pentahydrate and 14.4g of sodium hydroxide were dispersed in 80ml of deionized water, and stirred at room temperature for 2 hours to obtain a mixed solution. Use a measuring cylinder to measure 60ml of the obtained mixed solution, pour it into a 100ml Teflon lining, put the lining into the matching stainless steel outer lining, place the whole in a well-type furnace, and raise the temperature to 200°C and keep at this temperature for 12h. Pour the final solution and the precipitate into a centrifuge tube, wash with deionized and absolute ethanol three times, centrifuge at 10000r / min for 5min, pour off the unreacted precursor solution, and place the precipitate in an oven Dry at 80°C for 12h to obtain NB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com