SCR urea solution mixer

A solution mixing and mixer technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of poor mixing uniformity of urea solution and exhaust gas, low NOx conversion efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0028] In conjunction with the accompanying drawings.

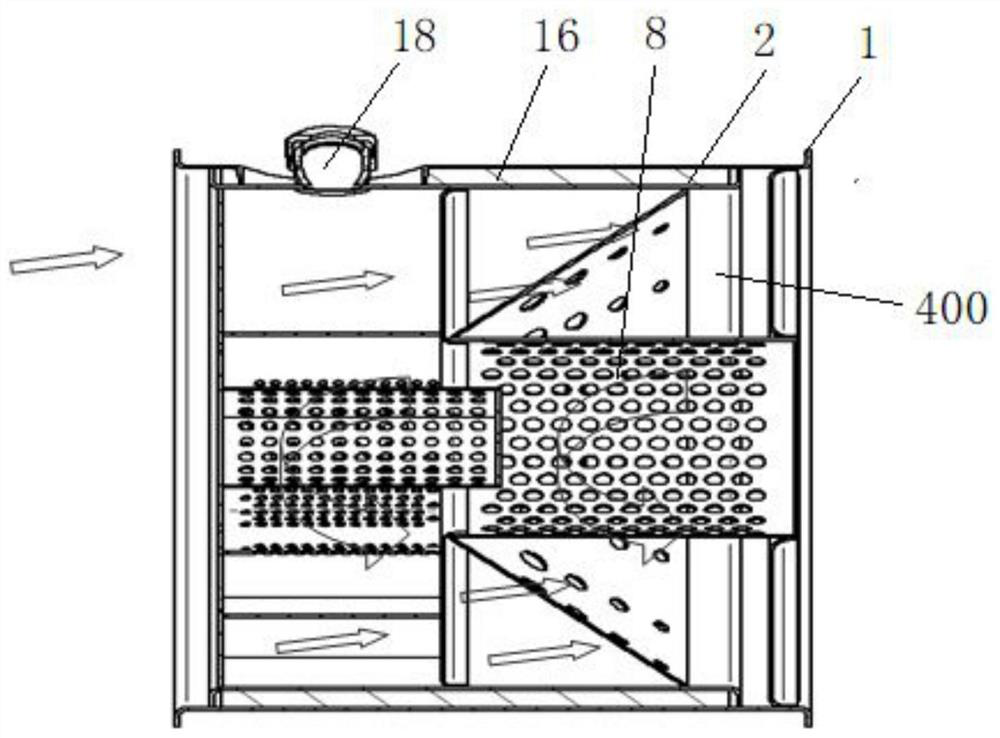

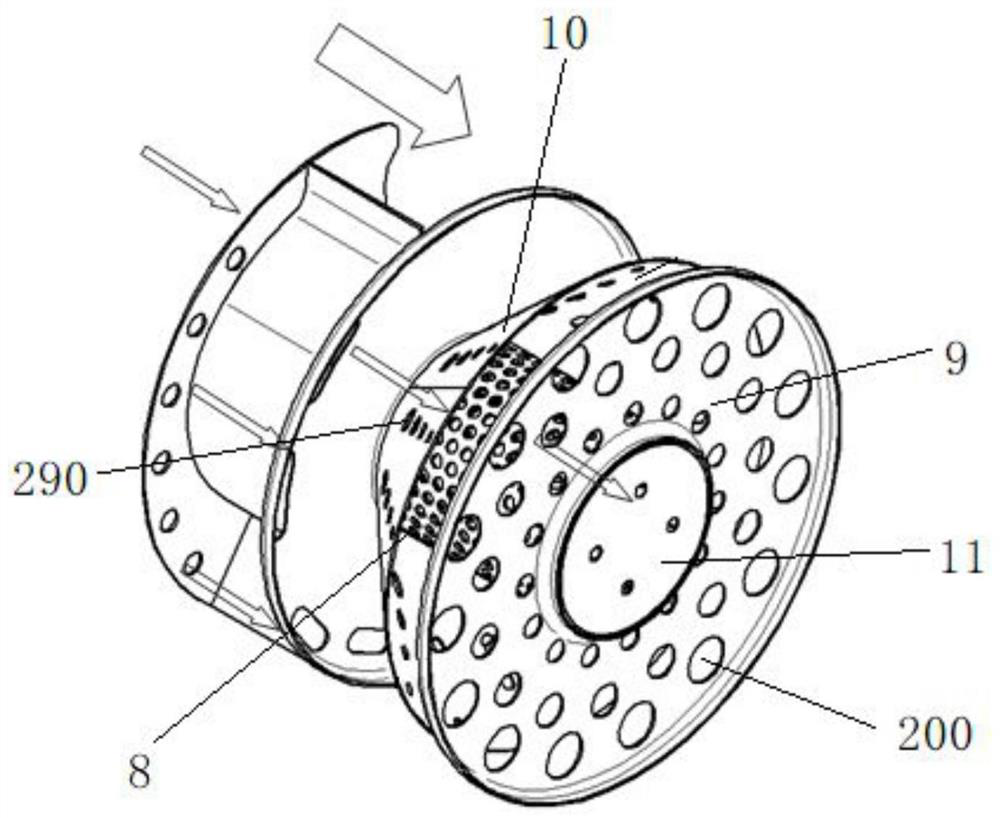

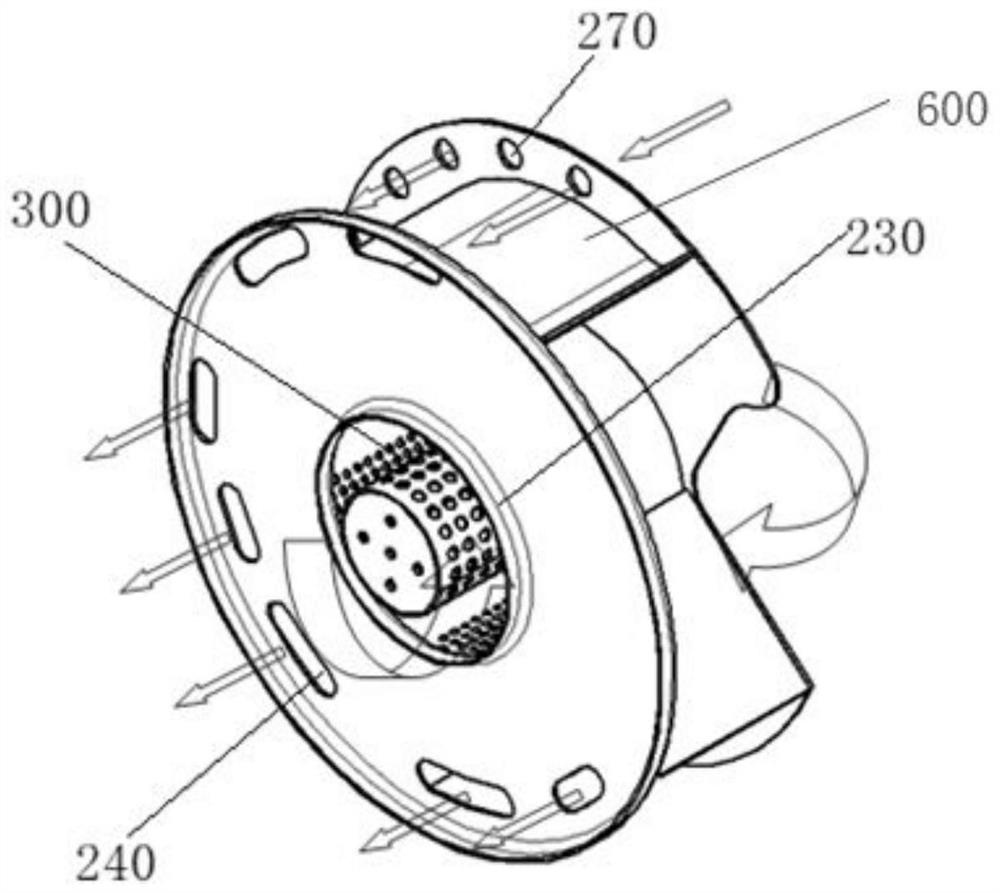

[0029] The invention provides an SCR urea solution mixer device. The mixer adopts spiral blades to guide the urea solution and vehicle exhaust gas entering the mixer. The perforation effect of the equalizing pipe carries out the second atomization thermal decomposition, enters the large equalizing pipe under the action of the exhaust gas flow, passes through the porous equalizing plate, and decomposes the urea solution for the third time. The mixer of the invention increases the stroke of the mixing path and improves the uniformity of ammonia gas distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com