Method for rapidly removing organic templating agent in mesoporous material with solvent extraction method

An organic template agent and mesoporous material technology, applied in chemical instruments and methods, inorganic chemistry, molecular sieve compounds, etc., can solve the problems of long process cycle, cumbersome operation steps, harsh experimental conditions, etc., to shorten the process cycle and simplify the operation. effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The first step of the implementation process of this embodiment is the same as the first step of the comparative example.

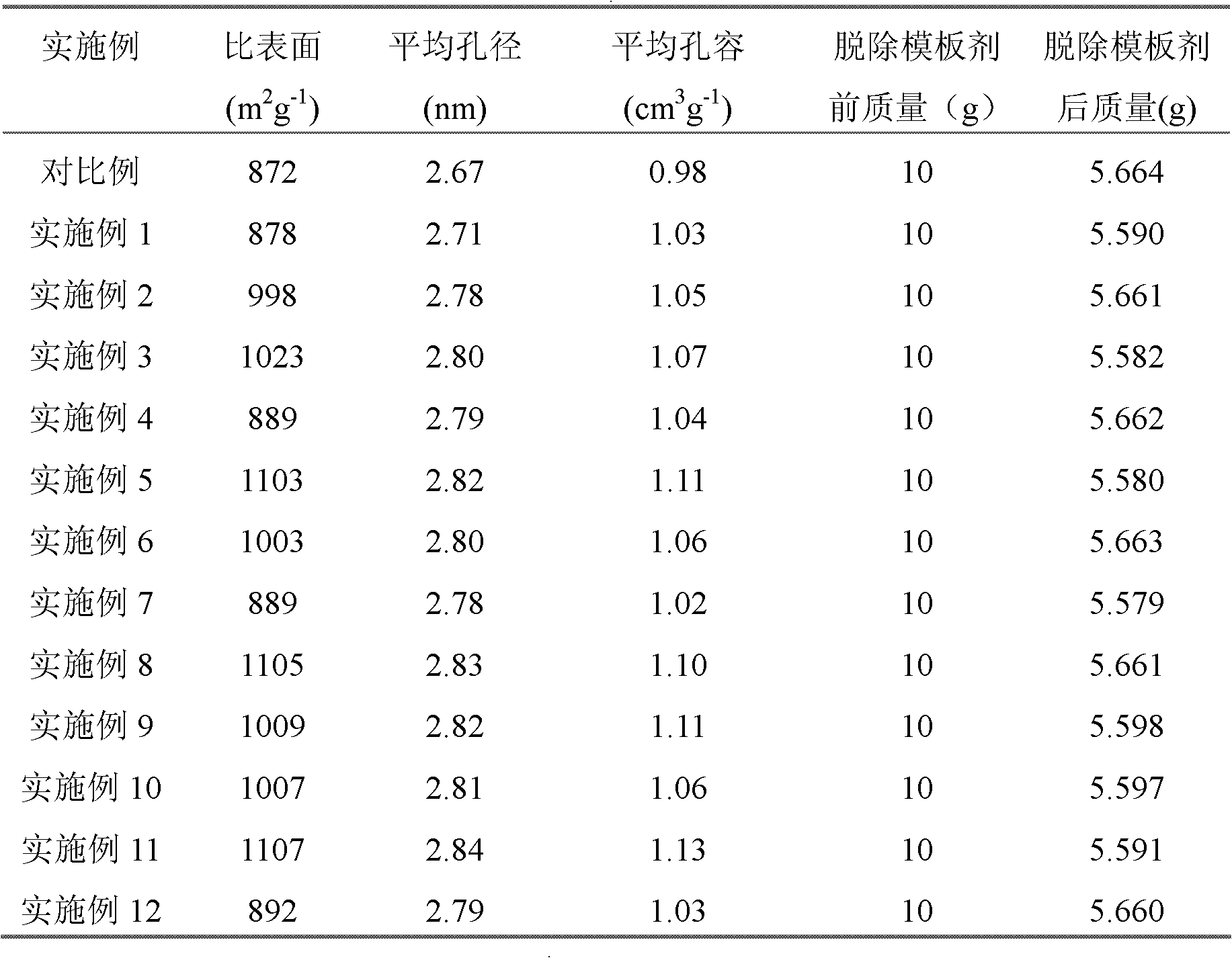

[0021] In the second step, 10 g of MSU was placed in 10 g of hydrochloric acid, acidified for 3 hours, filtered, and placed in a Soxhlet extractor. Add 50g of methanol solvent and 5g of n-hexane additive into the three-neck flask at the bottom of the Soxhlet extractor. After the solvent has been refluxed for 12 hours, stop heating and cool to room temperature. After taking out the white powder of MSU, wash it with deionized water for 3 to 5 The second time, the MSU mesoporous material was obtained after drying at 110°C for 24 hours. The measurement results of its specific surface area, pore volume, and pore diameter are shown in Table 1. The quality results of MSU mesoporous materials before and after removing the template are shown in Table 1.

Embodiment 2

[0023] The first step of the implementation process of this embodiment is the same as the first step of the comparative example.

[0024] In the second step, 10 g of MSU was placed in 20 g of hydrochloric acid, acidified for 6 hours, filtered, and placed in a Soxhlet extractor. Add 70g of ethanol solvent and 8g of n-hexane additive to the three-necked flask at the bottom of the Soxhlet extractor. After the solvent has been refluxed for 18 hours, stop heating and cool to room temperature. After taking out the white MSU powder, wash it with deionized water for 3 to 5 The second time, the MSU mesoporous material was obtained after drying at 110°C for 24 hours. The measurement results of its specific surface area, pore volume, and pore diameter are shown in Table 1. The quality results of MSU mesoporous materials before and after removing the template are shown in Table 1.

Embodiment 3

[0026] The first step of the implementation process of this embodiment is the same as the first step of the comparative example.

[0027] In the second step, 10 g of MSU was placed in 40 g of hydrochloric acid, acidified for 9 hours, filtered, and placed in a Soxhlet extractor. Add 120g of ethanol solvent and 15g of n-octane additive to the three-necked flask at the bottom of the Soxhlet extractor. After the solvent has been refluxed for 24 hours, stop heating and cool to room temperature. After taking out the white powder of MSU, wash it with deionized water for 3~ After drying for 5 times at 110°C for 24 hours, the MSU mesoporous material was obtained. The measurement results of specific surface area, pore volume, and pore diameter are shown in Table 1. The quality results of MSU mesoporous materials before and after removing the template are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com