Method and apparatus for preparing sheet-type metal pwoder by atomized drop deformation

A flake metal and powder technology, applied in the field of metal powder preparation, can solve the problems of difficulty in preparing flake powder, cumbersome process operation, long process cycle, etc., and achieve the effects of reducing the degree of oxidation, simplifying the process process, and shortening the process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

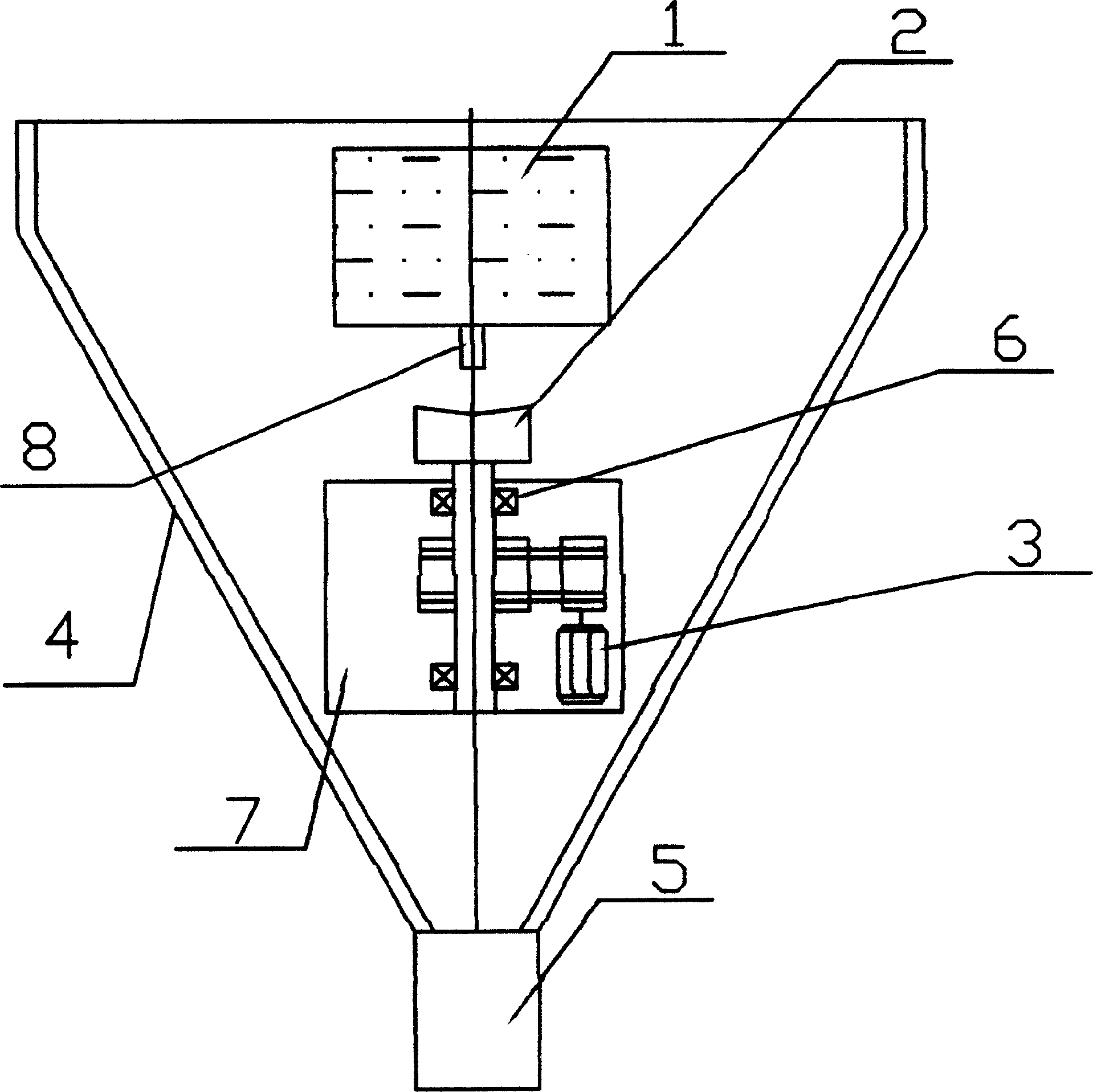

[0021] Such as figure 1 As shown, the special equipment of the present invention includes a melting crucible 1 placed in a closed atomization chamber 4, a rotary atomizer 2, a bearing 6 and a driving motor 3. Wherein, the turntable atomizer 2 is located below the melting crucible 1, and is a concave turntable with a certain taper. The bearing is installed on the rotating shaft of the atomizer. The outer side of the rotating shaft is covered with a water cooling chamber 7, and the motor is placed in the water cooling chamber. The powder collecting tank 5 is connected to the bottom of the atomization chamber 4: the diameter of the rotary atomizer is Φ35mm, and the motor is a high-speed motor driven by a belt.

[0022] Take 2 kg of metallic silver and put it into a crucible with a leak. Vacuum the spray chamber to 2×10 -2 Pa, and then filled with high-purity argon, the pressure is -0.05MPa. Heat the metallic silver to 1100°C to melt it, use a high-speed motor to accelerate the...

Embodiment 2

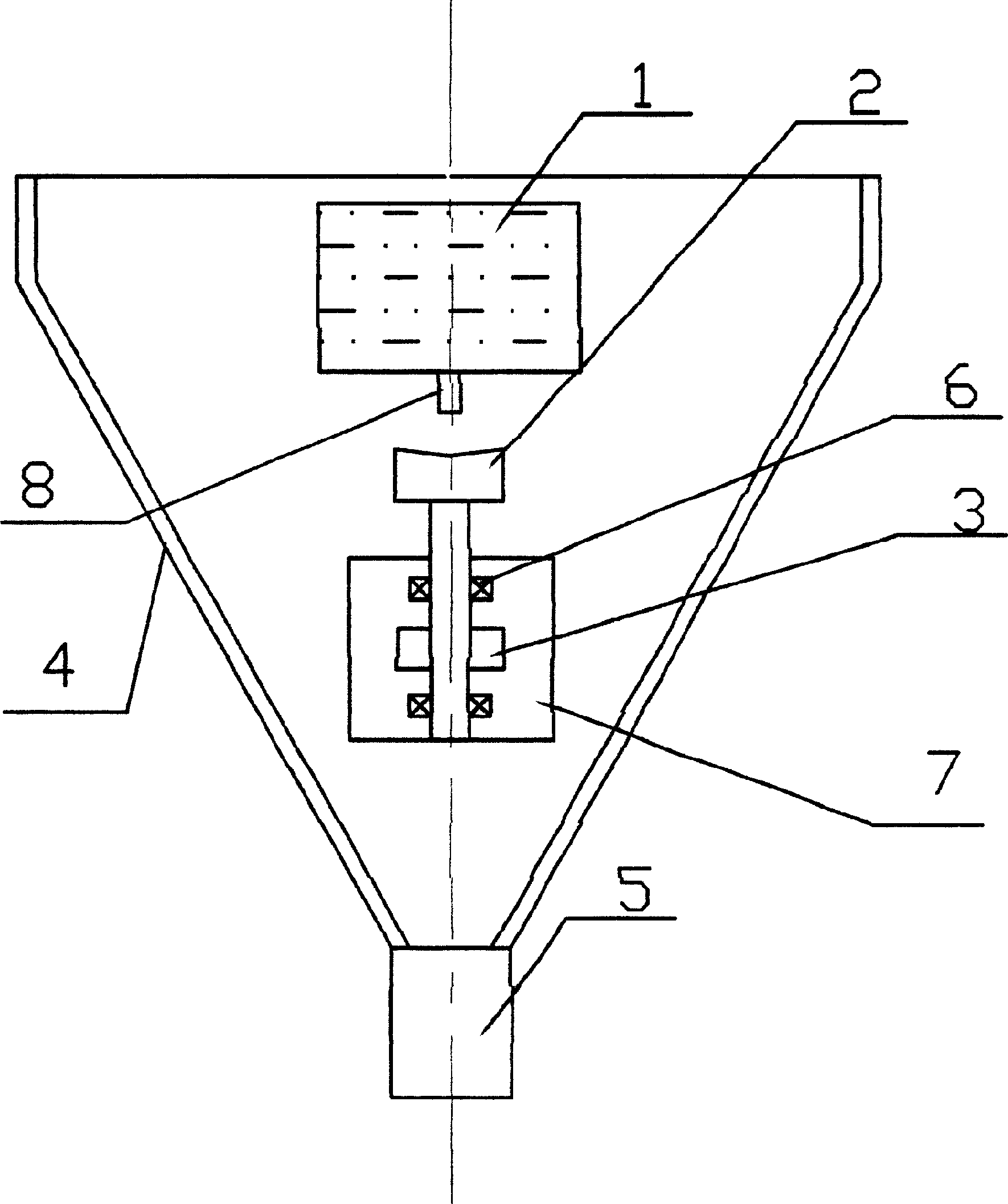

[0024] Such as figure 2 As shown, the diameter of the rotary atomizer is Φ25mm, and the motor is a high-speed motor coaxial with the atomizer.

[0025] Take 2 kg of metallic silver and put it into a crucible with a leak. Vacuum the spray chamber to 2×10 -2 Pa, and then into high-purity argon, the pressure is -0.02MPa. Heat metallic silver to 1200°C to melt it, use a high-speed motor to accelerate the turntable atomizer to 25,000 rpm, open the stopper at the leak, and the melt flows out from the leak 8 at a flow rate of 10 g / s. First, it is centrifugally atomized into tiny droplets, and controlled cooling to achieve a certain degree of supercooling, and then collides with the wall of the atomization chamber to form a sheet. The aspect ratio of the sheet is 80-200, and the oxygen content of the powder is 80ppm.

Embodiment 3

[0027] The diameter of the turntable atomizer is Φ30mm, and the motor is a high-speed motor coaxial with the atomizer. Take 2 kg of metal aluminum and put it into a crucible with a leak. Vacuum the spray chamber to 3×10 -2 Pa, and then filled with high-purity argon, the pressure is 0.05MPa. Heat the metal aluminum to 800°C to melt it, use a high-speed motor to accelerate the turntable atomizer to 45,000 rpm, open the stopper at the leak nozzle, and the melt flows out from the nozzle 8 at a flow rate of 10 g / s. First, it is centrifugally atomized into tiny liquid droplets, and through controlled cooling to achieve a certain degree of supercooling, and then collides with the wall of the atomization chamber and deforms into sheets with an aspect ratio of 200-300.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com