Bacterial cellulose porous thin film and preparation method thereof

A bacterial cellulose and porous film technology, applied in electrical components, electrochemical generators, circuits, etc., can solve the problems of long drying cycle, complex process, high energy consumption, etc., and achieve the effect of short process cycle and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Pre-compress a 10 cm thick bacterial cellulose wet film under a pressure of 0.01 MPa for 30 seconds, soak the pre-compressed bacterial cellulose film in acetone for 5 min, and then replace the bacterial cellulose film with acetone at 0.01 Under the pressure of MPa, carry out hot-press drying for 5 minutes, and the heating temperature is 80 o c. A bacterial cellulose porous film was obtained.

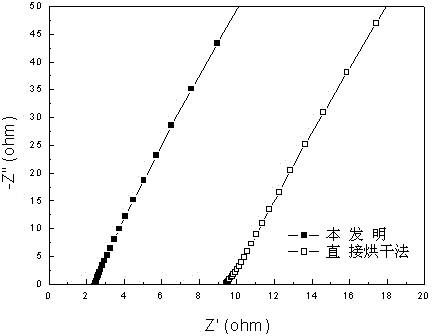

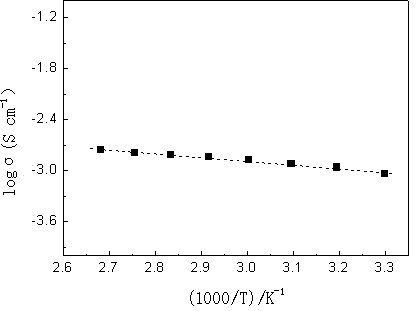

[0027] The main chemical composition of the bacterial cellulose porous film is bacterial cellulose, the thickness of the film is less than 20 microns, the porosity is greater than 50%, and it has high ion conductivity in the electrolyte (such as figure 2 shown).

[0028]

Embodiment 2

[0030] A 15 cm thick bacterial cellulose wet film was pre-compressed under a pressure of 0.05 MPa for 15 seconds, and the pre-compressed bacterial cellulose film was soaked in methanol for 10 min, and then the methanol-substituted bacterial cellulose film was placed at 0.05 Carry out hot-press drying under MPa pressure for 10 min, heating temperature is 60 o c. A bacterial cellulose porous film was obtained.

[0031] The main chemical component of the bacterial cellulose porous film is bacterial cellulose, the thickness of the film is less than 30 microns, the porosity is greater than 50%, and the ion conductivity in the electrolyte is similar to that of Example 1.

[0032]

Embodiment 3

[0034] The 8 cm thick bacterial cellulose wet film was pre-compressed under 0.1MPa pressure for 2 seconds, the pre-compressed bacterial cellulose film was soaked in ethanol for 15 min, and then the bacterial cellulose film after ethanol replacement was placed in 0.1 Under the pressure of MPa, hot-press drying was carried out for 15 minutes, and the heating temperature was 40 o c. A bacterial cellulose porous film was obtained.

[0035] The main chemical component of the bacterial cellulose porous film is bacterial cellulose, the thickness of the film is less than 20 microns, the porosity is greater than 50%, and the ion conductivity in the electrolyte is similar to that of Example 1.

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com