Method for producing sulfamate-series water reducing agent and equipment for producing sulfamate-series water reducing agent

The technology of a sulfamic acid salt and production method is applied in the field of production method and the equipment used therein, which can solve problems such as unsatisfactory product quality stability, low product quality rate, and endangering the health of employees, so as to achieve stability improvement and process improvement. The effect of short cycle and no discharge of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

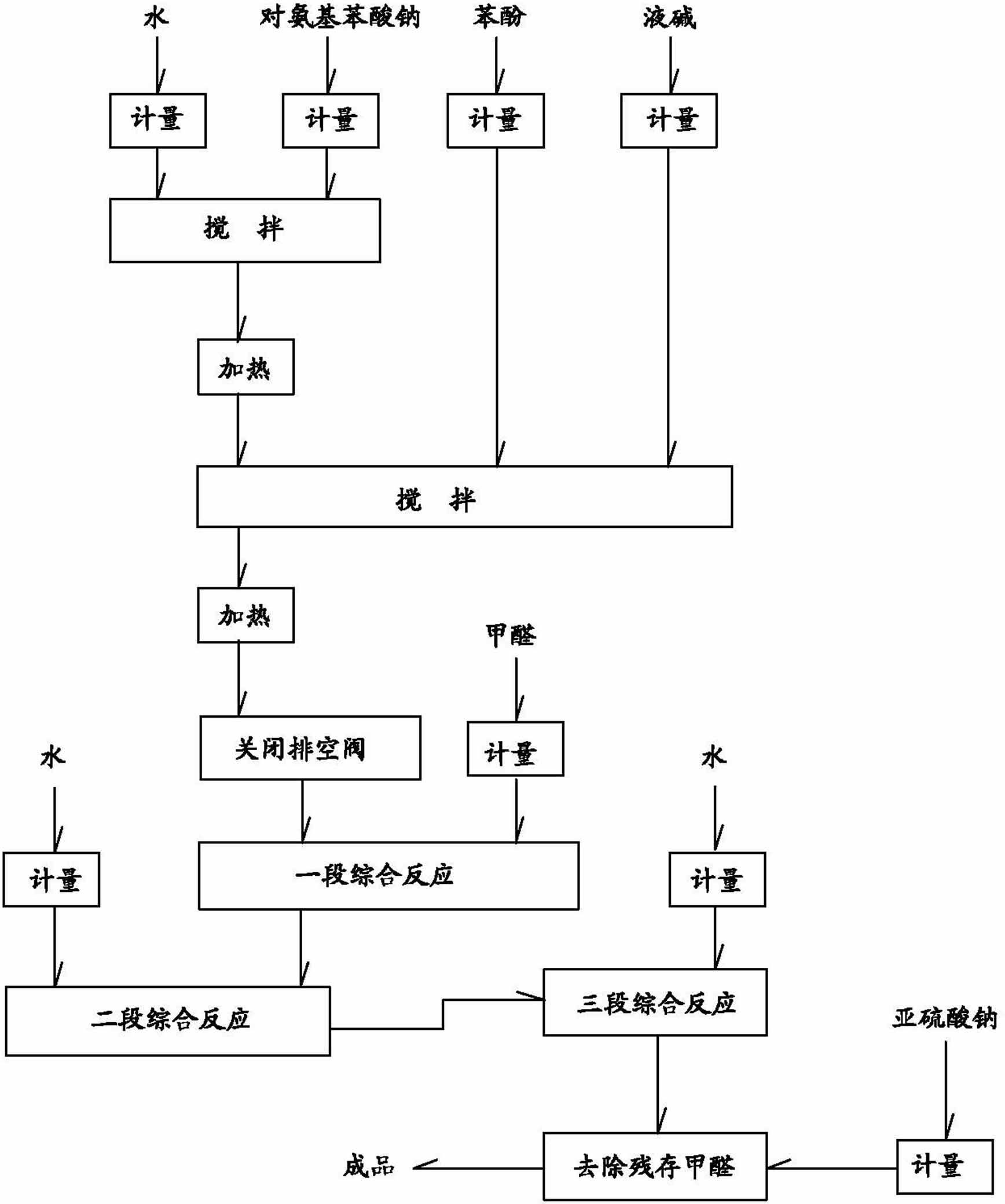

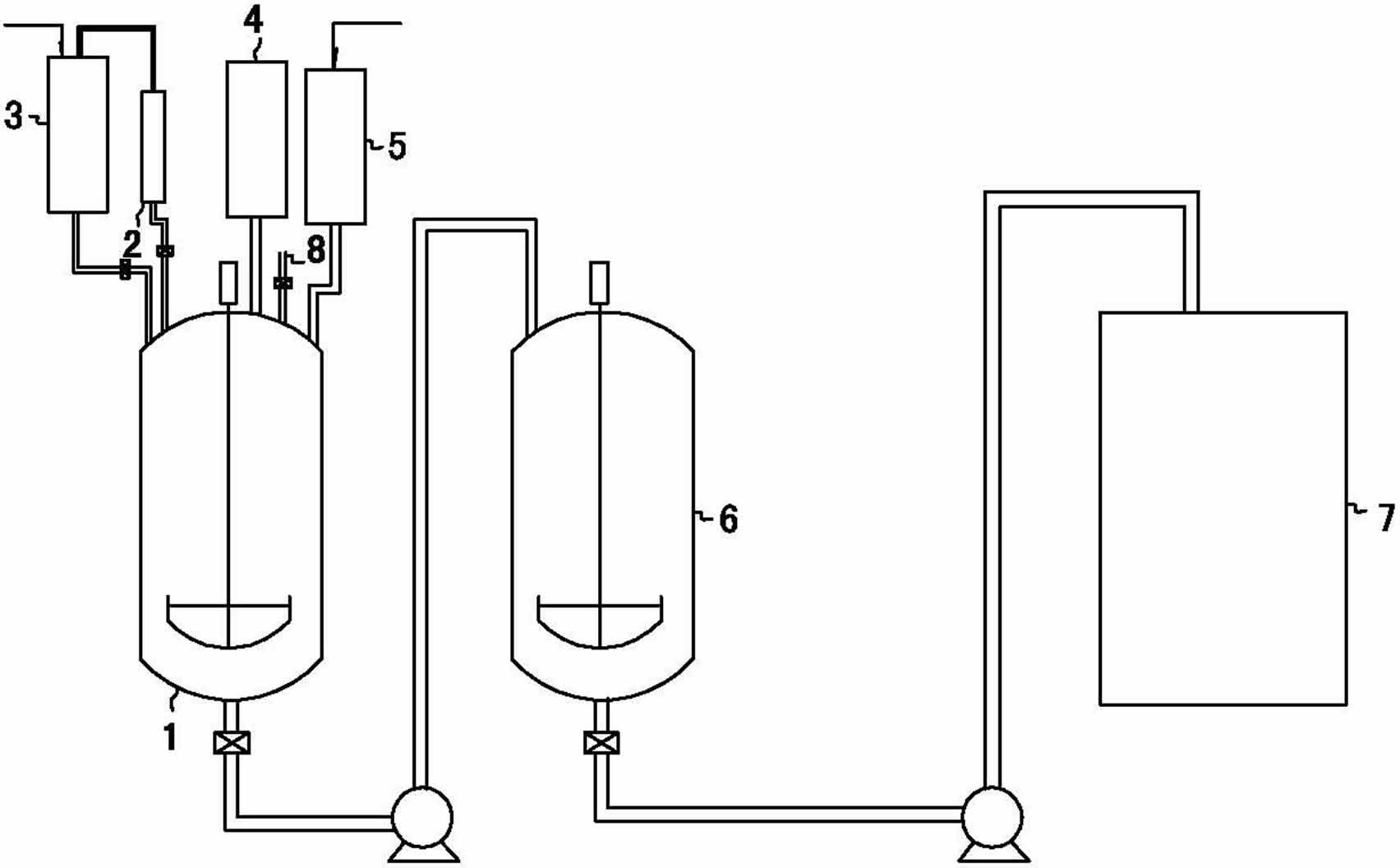

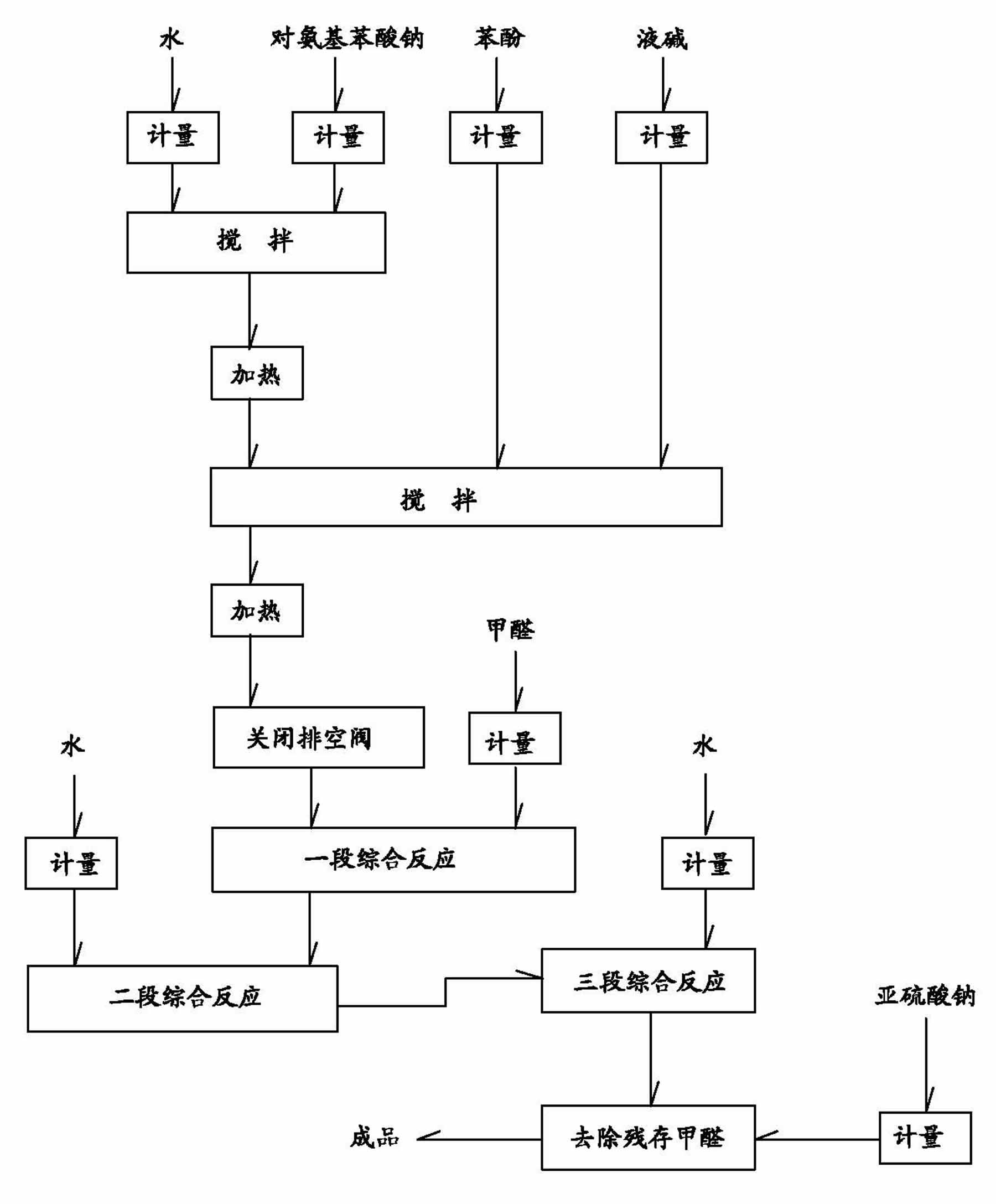

Method used

Image

Examples

Embodiment 2

[0062] Add 1350kg of water into the reactor, 780kg of sodium p-aminobenzene sulfonate into the reactor, one-time continuous input from the manhole, and 240kg of liquid caustic soda (40% NaOH solution) from the high tank into the reactor ( Add through the pipeline, close the valve in time after adding). Start stirring, and use steam to heat the materials in the reactor to 45 degrees through the interlayer. Add 570kg of phenol (one-time addition of flow rate without special requirements), heat to 60°C, add 1000kg of formaldehyde dropwise within 60-70 minutes, keep the temperature at 98-102°C for 40 minutes, add 300kg of water to the kettle, and Pass cooling water to the interlayer, keep it for 2.5 hours at a temperature of 93 degrees, add 300 kg of water to the kettle, cool the interlayer of the kettle, keep it at 60 degrees for 2 hours, add 50 kg of sodium sulfite, and continue the reaction for 30 minutes. Add 750kg of water to the kettle, stir for another 30 minutes, and pump...

Embodiment 3

[0064] Add 1300kg of water to the reactor, 800kg of sodium p-aminobenzene sulfonate into the reactor, one-time continuous input from the manhole, and 240kg of liquid caustic soda (40% NaOH solution) from the high tank into the reactor ( Add through the pipeline, close the valve in time after adding). Start stirring, and use steam to heat the materials in the reactor to 45 degrees through the interlayer. Add 600kg of phenol (one-time adding flow rate without special requirements), heat to 65°C, add 1000kg of formaldehyde dropwise within 60-70 minutes, keep the temperature at 98-102°C for 40 minutes, add 300kg of water to the kettle, and Pass cooling water to the interlayer, keep it for 2.5 hours at a temperature of 93 degrees, add 300 kg of water to the kettle, cool the interlayer of the kettle, keep it at 60 degrees for 2 hours, add 50 kg of sodium sulfite, and continue the reaction for 30 minutes. Add 750kg of water to the kettle, stir for another 30 minutes, and pump the mo...

Embodiment 4

[0066] Add 1350kg of water into the reactor, 820kg of sodium p-aminobenzene sulfonate into the reactor, one-time continuous input from the manhole, and 240kg of liquid caustic soda (40% NaOH solution) from the high tank into the reactor ( Add through the pipeline, close the valve in time after adding). Start stirring, and use steam to heat the materials in the reactor to 45 degrees through the interlayer. Add 5800kg of phenol (one-time addition of flow rate without special requirements), heat to 70°C, add 1000kg of formaldehyde dropwise within 60-70 minutes, keep the temperature at 98-102°C for 40 minutes, add 300kg of water to the kettle, and Pass cooling water to the interlayer, keep it for 3 hours at 92 degrees, add 300 kg of water to the kettle, cool the interlayer, keep it at 60 degrees for 2 hours, add 50 kg of sodium sulfite, and continue the reaction for 30 minutes. Add 750kg of water to the kettle, stir for another 30 minutes, and pump the mother liquor of the sulfam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com