Ceramic component with cavity structure and preparing method of ceramic component

A ceramic and inner cavity technology is applied in the field of ceramic components with inner cavity structure and their preparation, which can solve the problems of inability to apply high-strength injection molding, inability to realize industrial production, and limited design flexibility, and achieve accurate size and shape. , The effect of strong aesthetics and high equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

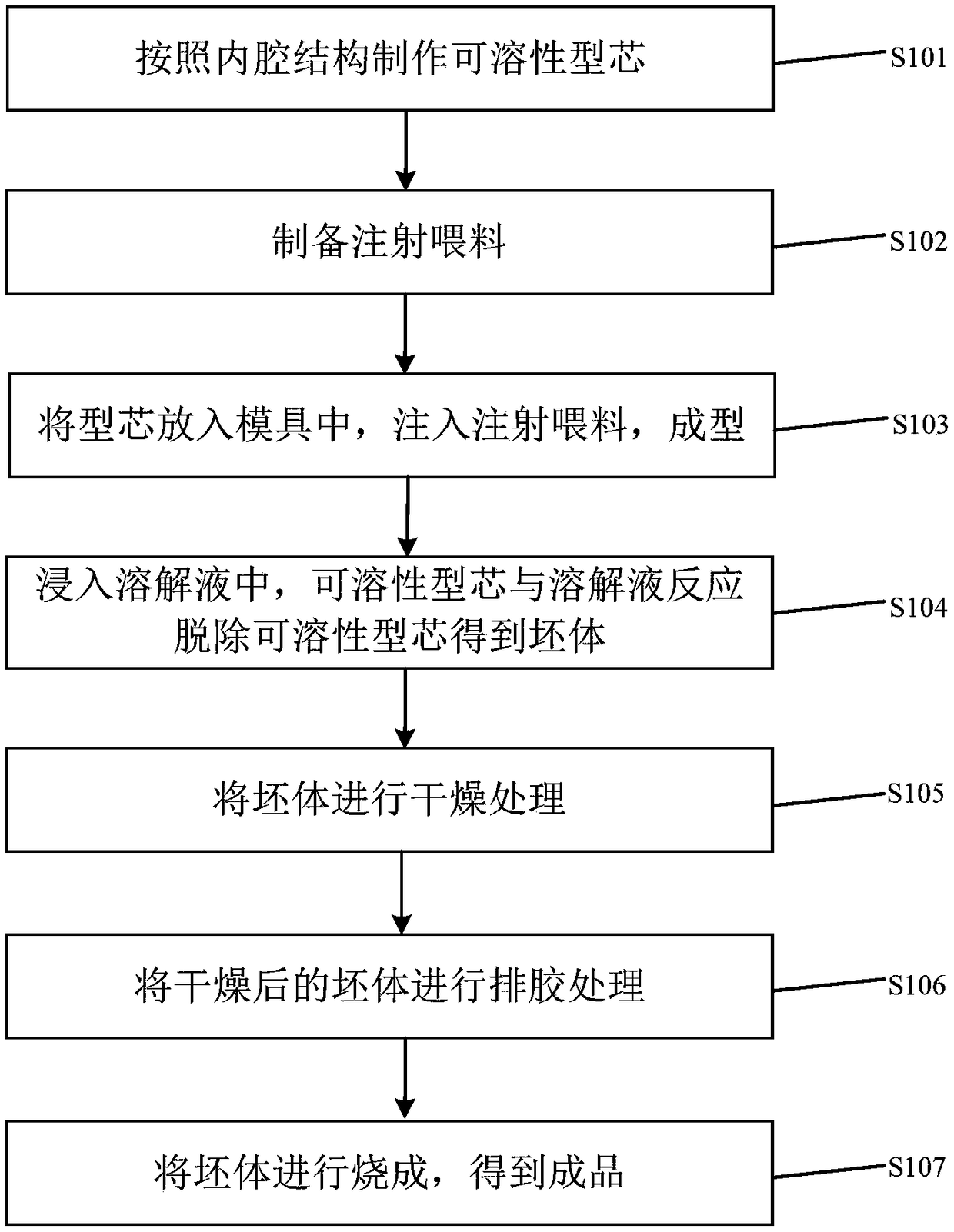

[0039] The invention provides a method for preparing a ceramic component with an inner cavity structure, comprising:

[0040] S101: making a soluble core according to the cavity structure;

[0041] According to the cavity structure of the ceramic component to be prepared, the core is prepared with polar thermoplastic. The molding method of the core can be 3D printing molding, injection molding and isostatic pressing molding, but not limited thereto. Among them, the more economical and applicable method is to use the injection molding method to form the core, which mainly includes: heating the polar thermoplastic to the melting temperature, injecting it into the mold, and obtaining the core to be used after cooling. The core material needs to ensure a high degree of smoothness, without defects such as burrs on the surface, and the core can be polished if necessary. In addition, the shape of some cores can be very complex. At this time, 3D printing can be considered to form th...

Embodiment 1

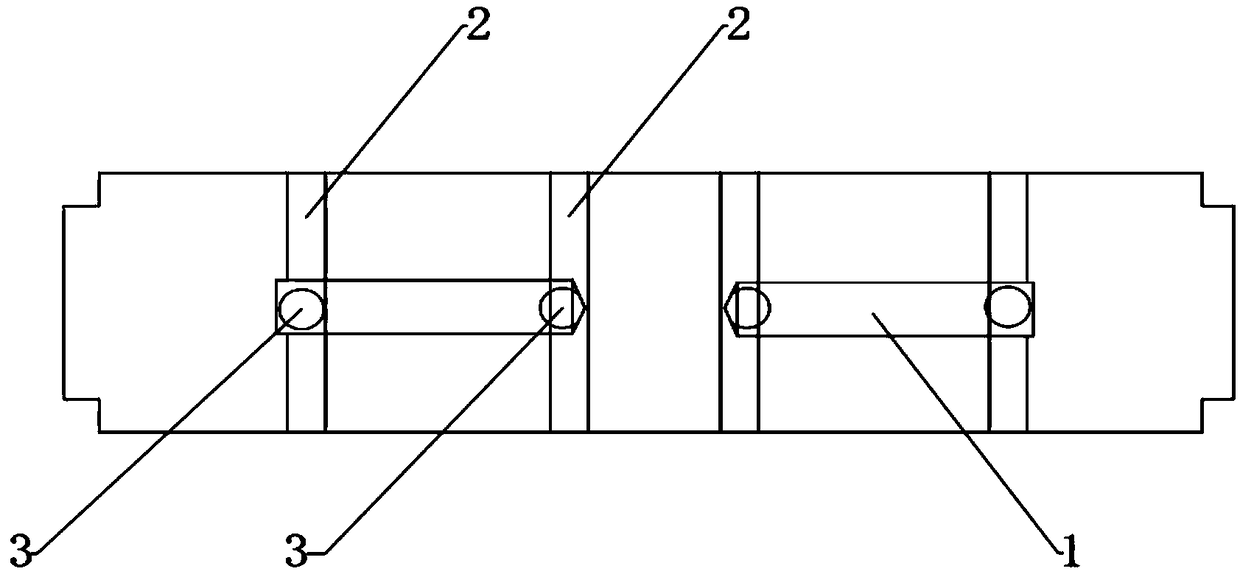

[0070] (1) According to the shape of the inner cavity structure 1, polyvinyl chloride is used to prepare the core by injection molding; after molding, it can be selected to carry out appropriate polishing according to its surface condition, so as to obtain a core with higher smoothness and no burrs;

[0071] (2) Alumina powder is mixed with paraffin, and granulated to obtain injection powder;

[0072] (3) Put the core into the mold and fix the core through the thimble; heat the injection powder in the injection machine to transform it into a viscous melt; and inject it into the mold under the working conditions of 110°C and 80MPa pressure; Cooling, removing the outer mold to obtain a ceramic blank;

[0073] (4) Immerse in methylene chloride after the ceramic blank is cooled, dissolve and remove the polyvinyl chloride core, take it out from the solution after 40 hours to obtain the green body;

[0074] (5) Place the green body in a ventilated position to air dry;

[0075] (6)...

Embodiment 2

[0078] (1) According to the shape of the inner cavity structure 1, polystyrene is used to prepare the core by injection molding; after molding, it can be selected to perform appropriate polishing according to its surface condition, so as to obtain a core with higher smoothness and no burrs;

[0079] (2) Alumina powder is mixed with paraffin, and granulated to obtain injection powder;

[0080] (3) Put the core into the mold and fix the core through the thimble; heat the injection powder in the injection machine to transform it into a viscous melt; and inject it into the mold under the working conditions of 150°C and 100MPa pressure; Cooling, removing the outer mold to obtain a ceramic blank;

[0081] (4) Immerse in toluene after the ceramic blank is cooled, dissolve and remove the polystyrene core, take it out from the solution after 55 hours to obtain the green body;

[0082] (5) Place the green body in an oven and dry it at 50°C;

[0083] (6) Transfer the dried body to the ...

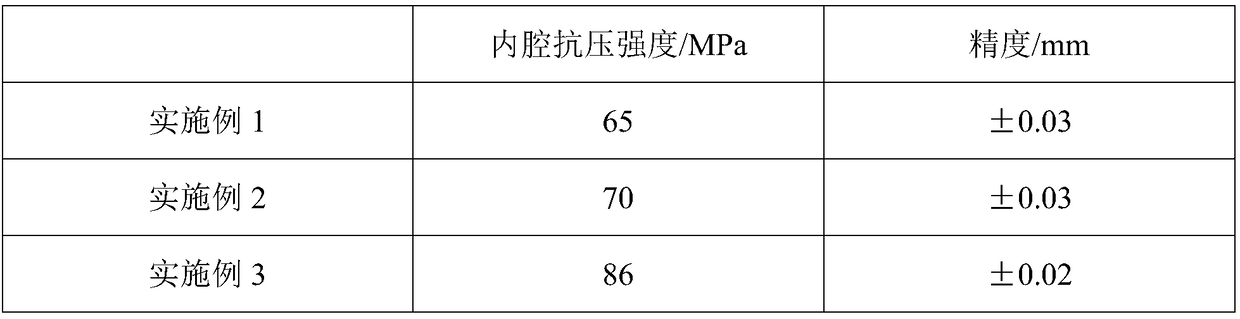

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com