High purity 4-hydroxyciclosporin and purification and preparation method thereof

A hydroxycyclosporine, high-purity technology, applied in the field of biopharmaceuticals, can solve the problem of high removal difficulty, and achieve the effects of shortening the process cycle, reducing the difficulty, and being difficult to recover and reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

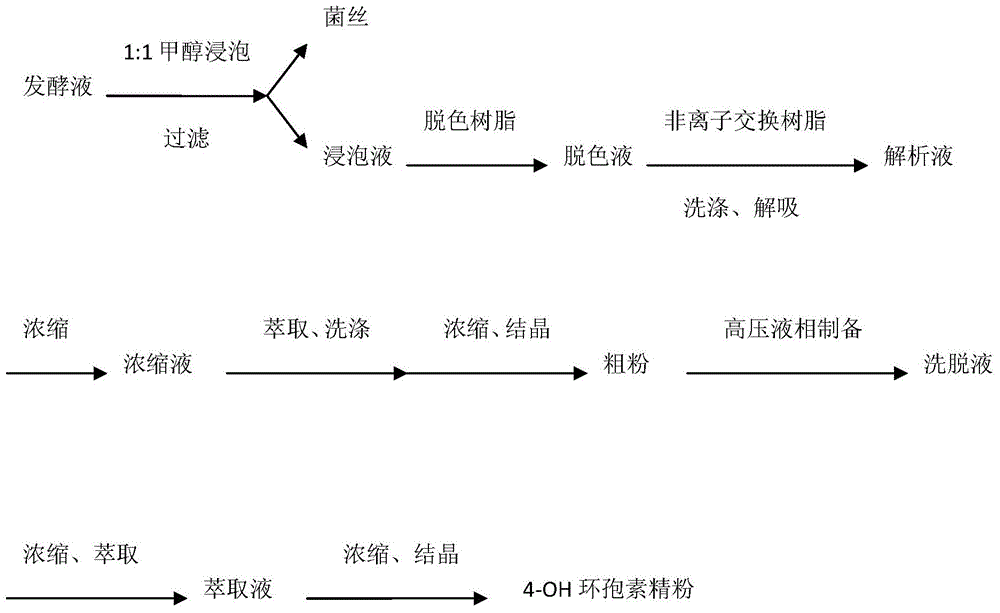

Method used

Image

Examples

Embodiment 1

[0058] 1) Take 30L of 4-OH cyclosporin fermentation broth, containing 10.2g of 4-OH cyclosporine, add 30L of isopropanol to soak for 5 hours, filter with plate and frame, collect 58L of extract, and the titer is 173 μg / ml.

[0059] 2) Use 1LD290 resin as the decolorization medium to decolorize the collected extraction solution at a flow rate of 2BV / h, and collect the decolorization solution, which is obviously shallower than before the column.

[0060] 3) Use a 1LHZ816 column to adsorb the collected decolorized solution, and the sample loading flow rate is 1BV / h. After the adsorption is completed, the titer of the column solution is detected to be 1 μg / ml, and discarded. The adsorbed resin is washed in one step, the detergent is 45% methanol, the flow rate is 1-1.5BV / h, and the washing column liquid has no unit after testing. Then analyze with 80% isopropanol at a flow rate of 1 BV / h, and collect the analysis solution in sections. When the outlet unit of the analysis solution...

Embodiment 2

[0064] 1) Take 25L of 4-OH cyclosporin fermentation broth, containing 8.2g of 4-OH cyclosporine, add 20L of ethanol to soak for 5 hours, filter with plate and frame, collect 41L of extract, and the titer is 189 μg / ml.

[0065] 2) Use 1LRX-01T resin as the decolorization medium to decolorize the collected extraction solution at a flow rate of 2BV / h, and collect the decolorization solution. The decolorization solution is obviously shallower than that before the column.

[0066] 3) Use a 1LHZ816 column to adsorb the collected decolorized solution, and the sample loading flow rate is 1BV / h. After the adsorption is completed, the titer of the column solution is detected to be 1 μg / ml, and discarded. The adsorbed resin is washed in two steps. The detergent 1 is 45% methanol-alkali (1g / LNaOH), and the detergent 2 is 45% methanol. The flow rate is 1-1.5BV / h. . Then analyze with 82% ethanol at a flow rate of 1 BV / h, and collect the analysis solution in sections. When the analysis exp...

Embodiment 3

[0070] 1) Take 28L of 4-OH cyclosporin fermentation broth, containing 9.8g of 4-OH cyclosporine, add 25L of methanol to soak for 5 hours, filter with plate and frame, collect 50L of extract, and the potency is 185 μg / ml.

[0071] 2) Use 1LRX-02T resin as the decolorization medium to decolorize the collected extraction solution at a flow rate of 2BV / h, and collect the decolorization solution, which is obviously shallower than before the column.

[0072] 3) Use a 1LHZ816 column to adsorb the collected decolorized solution, and the sample loading flow rate is 1BV / h. After the adsorption is completed, the titer of the column solution is detected to be 3 μg / ml, and discarded. The adsorbed resin is washed in two steps. The detergent 1 is 45% methanol-alkali (1g / LNaOH), and the detergent 2 is 45% methanol. . Then analyze with 80%-85% methanol, the flow rate is 1BV / h, and collect the analysis solution in sections. When the analysis export unit is less than 10 μg / ml, the analysis is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com