Method for extracting white mushroom lentinan assisted with ultrasonic wave

The technology of Agaricus bisporus and ultrasonic wave is applied in the direction of antitoxin, antibacterial drug, drug combination, etc., which can solve the problems of easily destroyed polysaccharide, complex process, many extraction steps, etc., and achieves a simple process of overcoming the limitation of production season and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for ultrasonically assisted extraction of Agaricus bisporus polysaccharides includes the following steps:

[0023] (1) Cut the fresh fruit bodies of Agaricus bisporus into small pieces, dry at 60°C, and crush to obtain crushed material;

[0024] (2) According to the water-to-material ratio of 30mL / g, add deionized water to the crushed material of step (1) and place it in an ultrasonic cleaner for hot water extraction. The extraction temperature is 65℃, the time is 40min, and the ultrasonic power is 170w. liquid;

[0025] (3) Centrifuge the extract of step (2), take the supernatant, and centrifuge the conditions: 5000rpm, 15min; use the same method to extract the precipitate, centrifuge, take the supernatant, and combine the 2 supernatants ;

[0026] (4). Concentrate the supernatant of step (3) at a temperature of 50°C under reduced pressure to 1 / 10 of the original volume to obtain a concentrated solution; add 3 times the volume of absolute ethanol to the concentrated ...

Embodiment 2

[0037] Optimization experiment of extraction conditions for the ultrasonic-assisted extraction of Agaricus bisporus polysaccharide

[0038] (1) Ultrasonic-assisted extraction of Agaricus bisporus polysaccharides extraction conditions optimization of single factor experiment

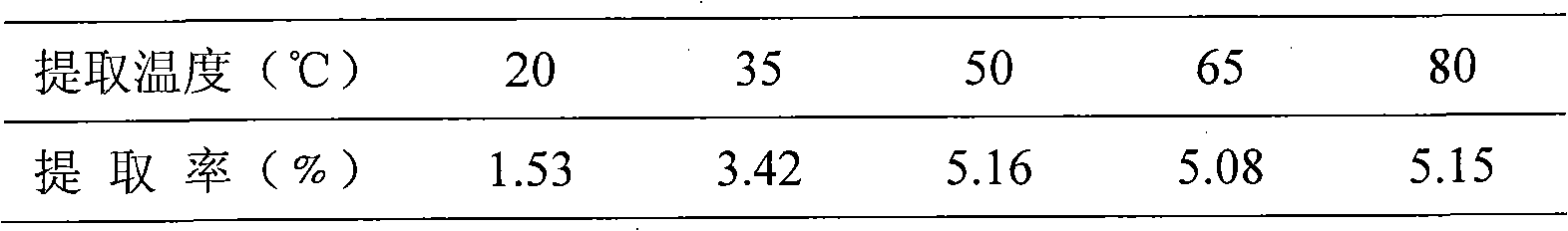

[0039] ①The effect of extraction temperature on the extraction rate of Agaricus bisporus polysaccharide.

[0040] The extraction temperature was set to five gradients of 20, 35, 50, 65, and 80°C, and the extraction time, ultrasonic power, and water-to-material ratio were 40 min, 170 w, and 40 mL / g, respectively. The extraction rate of polysaccharides at different extraction temperatures is shown in Table 1 below:

[0041]

[0042] It can be seen from Table 1 that the extraction rate of polysaccharides is the highest at 50°C, so 50°C is chosen as the center point of the following orthogonal experiment.

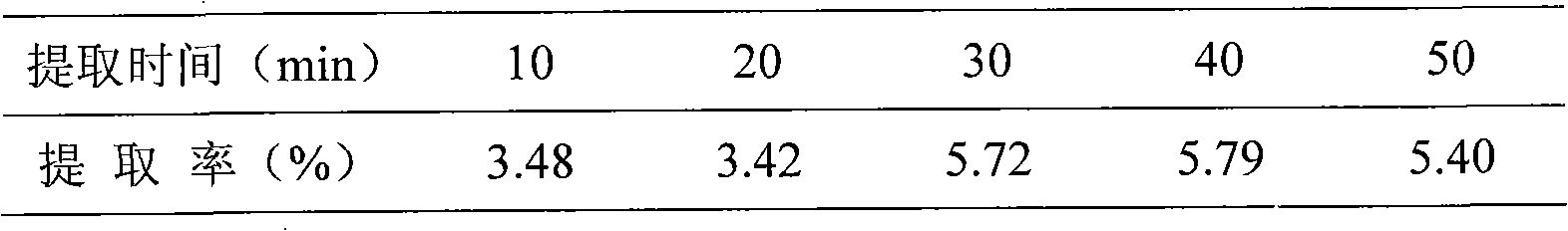

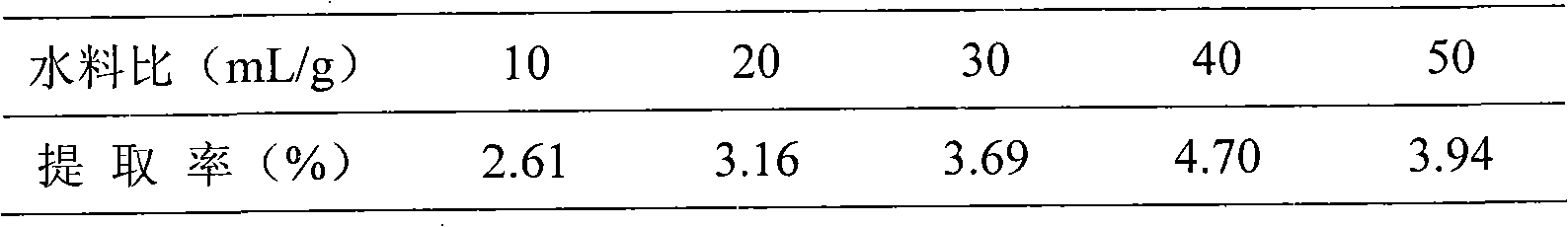

[0043] ②The effect of extraction time on the extraction rate of Agaricus bisporus polysaccharide.

[0044] Five g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com