Preparation for p-n junction hollow sphere and application in photocatalytic hydrogen production by water decomposition

A hollow sphere, p-n technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., to achieve simple and feasible process, increase hydrogen production yield, improve The effect of transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

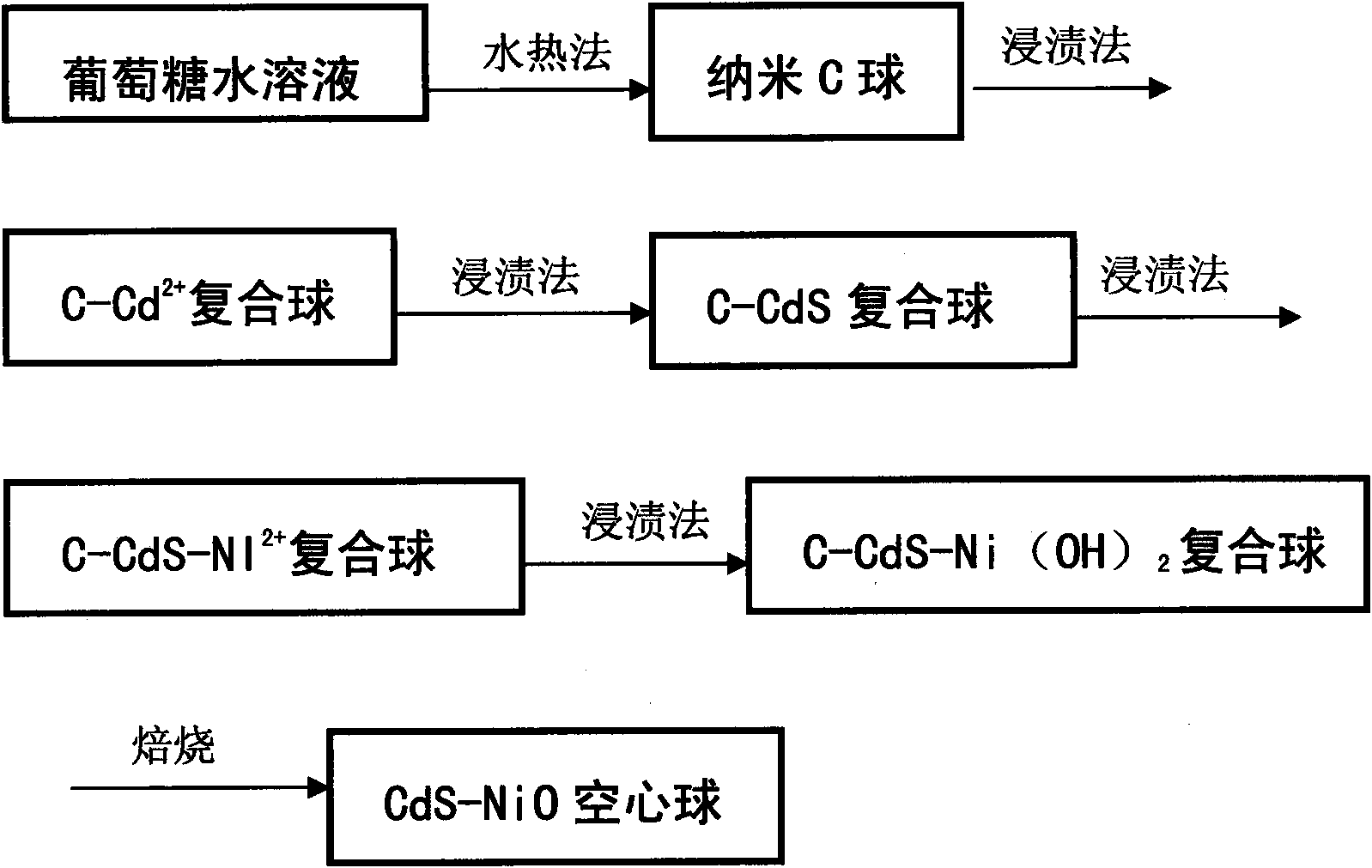

Method used

Image

Examples

Embodiment 1

[0089] Weigh 15g of glucose solid powder, measure 150mL of deionized water, dissolve glucose in deionized water, and stir evenly for 10min. The formed homogeneous solution was poured into a polytetrafluoroethylene-lined autoclave (volume 200 mL), heated in an oven to 165 °C, and kept at 165 °C for 5 h, then taken out and naturally cooled to room temperature. Filter, wash with deionized water and absolute ethanol three times respectively, and put the solid into a drying oven at 60° C. for 5 hours to obtain brown carbon nanospheres.

[0090] Weigh 10 g (0.83 mol) of the prepared carbon nanospheres, put them into a beaker, ultrasonicate for 30 min at a frequency of 31 Hz, and dry at 50 ° C; weigh 7 g (0.023 mol) of Cd(NO 3 ) 2 4H 2 O solid was added to 20 mL of deionized water to prepare an aqueous solution. This solution is impregnated in the carbon nanosphere of 10g, impregnates 2h, room temperature dries, makes the composite (C-Cd 2+ ).

[0091] Weigh 6.72g (0.028mol) Na ...

Embodiment 2

[0096] Weigh 1.25g of the hole sacrificial agent Na 2 S and 0.25g Na 2 SO 3 Dissolve in a 100mL Prex glass flat-bottomed reaction bottle with a flat lighted side containing 50mL of distilled water. Weigh 0.10 g of the p-n junction hollow sphere NiO-CdS nanocomposite material prepared in Example 1 and add it into the reaction flask.

[0097] Put the reaction bottle on the magnetic stirrer to stir, insert the three-way sampling glass bottle stopper into the reaction bottle, use the xenon lamp as the simulated sun light source, turn on the xenon lamp constant current power supply, and filter out the ultraviolet light of λ2 The results are shown in Table 1.

[0098] Table 1. p-n junction hollow sphere NiO-CdS solar visible light catalytic decomposition of water to produce H 2 result

[0099]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com