Synthesis of cyclic carbonic ester

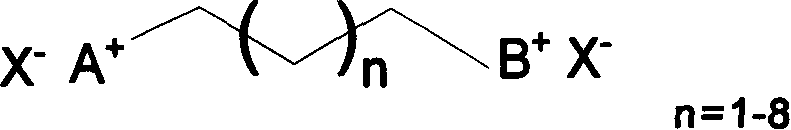

A technology of cyclic carbonate and synthesis method, which is applied in clean catalysis and green fields, can solve the problems of harsh reaction conditions, low stability, and low catalytic activity, and achieve convenient preparation, good thermal stability, and high catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027]

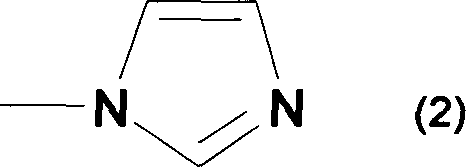

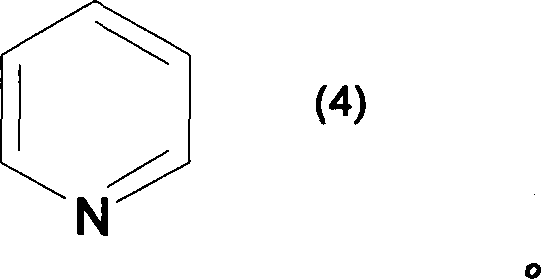

[0028] Implementation method: In a 100 ml stainless steel autoclave, add 0.0875 mmol of zinc bromide and 0.35 mmol of 1,2-bis(methylimidazolium) ethane bromide in sequence, and finally add 20 ml of propylene oxide (1a), and seal the reaction vessel , fill in carbon dioxide with an appropriate amount of pressure, and the temperature is slowly raised to 120°C controlled by the temperature controller, and then the pressure of carbon dioxide is controlled to 1.5MPa, reacted for 1 hour, cooled to room temperature, and unloaded. After the excess carbon dioxide is absorbed with saturated sodium carbonate solution, The resulting liquid was distilled under reduced pressure to obtain the product propylene carbonate (2a), which was weighed to calculate the yield. Through chromatography-mass spectrometry and NMR analysis, the product purity is greater than 99.0%, the separation yield is preferably 98.0%, and the selectivity is greater than 99.0%.

Embodiment 2

[0030] As in Example 1, the binary catalyst system used is zinc chloride and 1,2-bis(methylimidazolium)ethane bromide to obtain propylene carbonate (2a). The selectivity was 99.0%, and the yield was 96%.

Embodiment 3

[0032] As in Example 1, the binary catalyst system used is zinc iodide and 1,2-bis(methylimidazolium)ethane bromide to obtain propylene carbonate (2a). The selectivity was 99.0%, and the yield was 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com