Method for preparing aluminum oxide-silicon dioxide flexible aerogel thermal insulation felt

A flexible airgel and silicon dioxide technology, applied in the direction of protecting pipelines, mechanical equipment, heat exchange equipment, etc. through heat insulation, can solve the problems of high cost and complicated preparation process, and achieve low cost, simple process and flexible Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

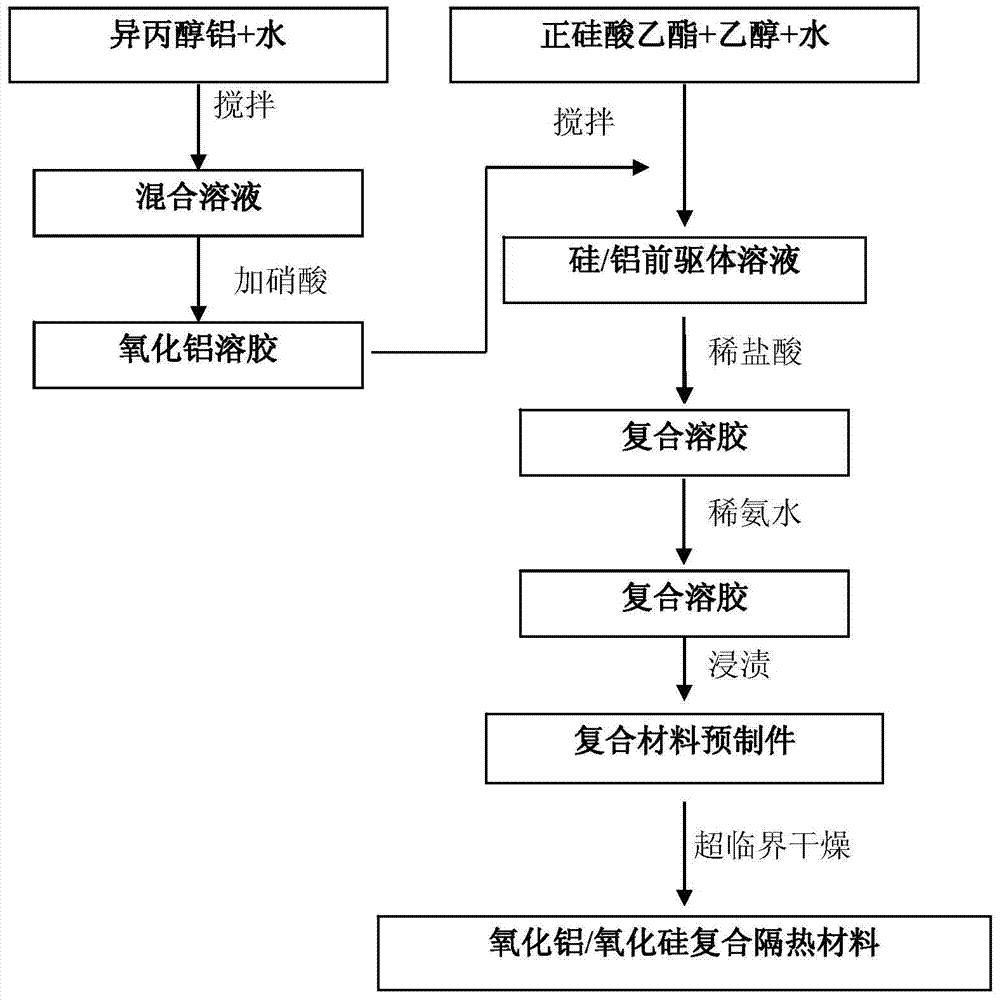

[0029] Such as figure 1 As shown, the flow process of this embodiment is as follows:

[0030] With the molar ratio of aluminum isopropoxide:water as 1:110, take 20g of aluminum isopropoxide and 180g of water, put them in a container, place the container in a water bath at 85°C and heat it to reflux, stir it electrically for 4 hours, add 0.1g of concentrated nitric acid, and continue stirring 4h to obtain alumina sol.

[0031] With the molar ratio of ethyl orthosilicate: ethanol: distilled water: alumina sol being 1:6:2:1, take 440mL of ethyl orthosilicate, 720mL of ethanol, 72mL of distilled water, and 36mL of alumina sol, and add them to the container in sequence. Stir electrically for 10 minutes, then add 150 mL of dilute ammonia water with 0.03 mol / L ethanol as the solvent, continue stirring for 10 minutes, and pour it into a stainless steel container with 10 mm thick aluminum silicate wool.

[0032] Put the stainless steel container into the autoclave, vacuumize it to -0...

Embodiment 2

[0034] With the molar ratio of aluminum isopropoxide: water as 1:200, take 20g of aluminum isopropoxide and 327g of water, put them in a container, place the container in a water bath at 85°C and heat it to reflux, stir it electrically for 4 hours, add 0.1g of concentrated nitric acid, and continue stirring 4h to obtain alumina sol.

[0035] With the molar ratio of methyl orthosilicate:methanol:distilled water:alumina sol being 1:8:10:5, take 440mL of ethyl orthosilicate, 960mL of ethanol, 108mL of distilled water, and 36mL of alumina sol, and add them to the container in sequence. Electric stirring for 30min, add 0.01mol / L dilute hydrochloric acid 35mL, continue to stir for 30min, then add 0.03mol / L ethanol as the solvent of dilute ammonia water 150mL, continue stirring for 10min, pour into the 10mm thick aluminum silicate wool in a stainless steel container.

[0036]After the sol is gelled, put the stainless steel container into the autoclave, vacuumize to -0.03MPa, flush n...

Embodiment 3

[0038] With the molar ratio of aluminum isopropoxide: water as 1:250, take 20g of aluminum isopropoxide and 409g of water, put them in a glass container, place the container in a water bath at 85°C and heat it to reflux, stir it electrically for 4 hours, add 0.1g of concentrated nitric acid, continue Stir for 4h to obtain alumina sol.

[0039] With the molar ratio of methyltrimethoxysilane: ethanol: distilled water: alumina sol being 1:20:4:2, take 440mL of ethyl orthosilicate, 3200mL of ethanol, 144mL of distilled water, and 72mL of alumina sol, and add them to the container in sequence , electric stirring for 10min, add 0.01mol / L dilute hydrochloric acid 35mL, continue stirring for 30min, then add 0.03mol / L ethanol as the solvent of dilute ammonia water 170mL, continue stirring for 6min, pour it into a stainless steel container with glass fiber .

[0040] Put the stainless steel container in the autoclave, after vacuuming to -0.03MPa, flush with nitrogen to 1MPa, heat at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com