Method for preparing nanometer silica micropowder

A nano-silicon micropowder and coarse pulverization technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of high preparation cost and complex process, and achieve the effect of low production cost and controllable size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

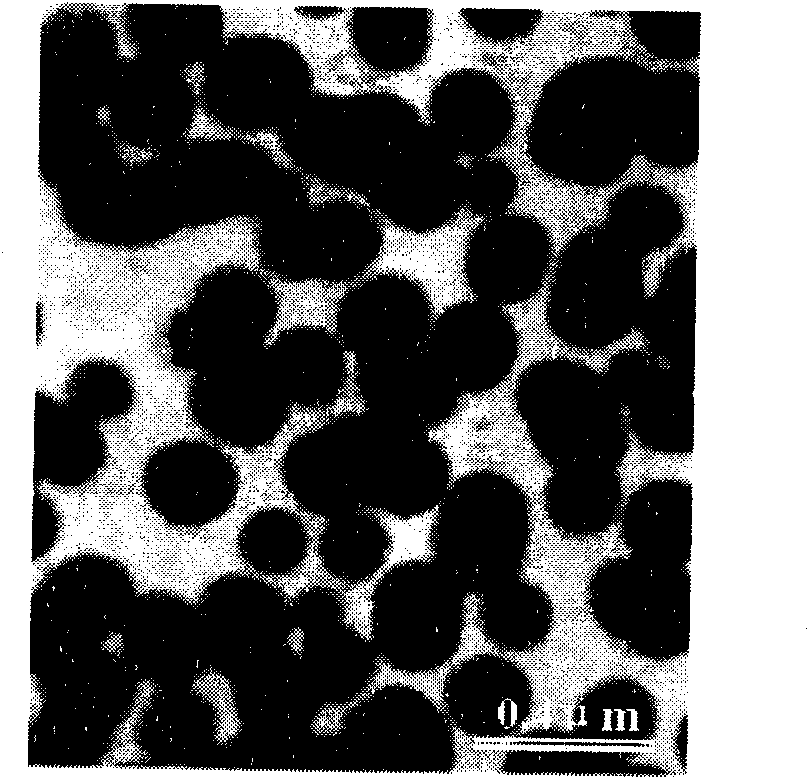

Image

Examples

Embodiment 1

[0024] Choose quartz sand (grain size 50 mesh) with a silica mass fraction not less than 99.5% as raw material, add industrial hydrochloric acid (qualified product, HCl content 31%, hydrochloric acid submerged in quartz sand) and soak for 10 hours, remove the acid solution and rinse with clean water Rinse repeatedly until the chloride ion content is below 0.1%. Use a ball mill to wet-grind to 800 mesh. The obtained grinding slurry will pass through a magnetic separator to remove free iron and then precipitate naturally. Then the sediment will be separated by mechanical means, and the sediment will be sent back to the wet grinding link to participate in grinding again. Add 3% (volume concentration) polyethylene glycol (PEG200) to the suspended matter slurry that removes sediment, adopt 0.5KW high-energy ultrasonic to disperse 5min, and obtain filter cake to suspension hydraulic filtration, and adopt high-energy ball milling method to filter The cake was ground to about 3000 mes...

Embodiment 2

[0026] Select quartz sand (with a particle size of 75 mesh) with a silica mass fraction not lower than 99.5% as raw material, add industrial hydrochloric acid (first-grade product, HCl content 33%, hydrochloric acid submerged in quartz sand) for 8 hours, remove the acid solution and use Rinse with clean water repeatedly until the chloride ion content is lower than 0.1%. Use a ball mill to wet-grind to about 900 meshes. The obtained grinding slurry will pass through a magnetic separator to remove free iron and then precipitate naturally. Then, the precipitate will be separated by mechanical means, and the precipitate will be sent back to the wet grinding link to participate in grinding again. Add 4% (volume content) sodium dodecylbenzene sulfonate in the suspension slurry that removes sediment, adopt 1.0KW high-energy ultrasonic dispersion 3min, and obtain filter cake to suspension hydraulic filtration, and adopt high-energy ball milling method to The filter cake was ground to ...

Embodiment 3

[0028] Choose quartz sand (grain size 100 mesh) with silica mass fraction not less than 99.5% as raw material, add industrial hydrochloric acid (first-grade product, HCl content 33%, hydrochloric acid submerged in quartz sand) and soak for 5 hours, remove the acid solution and use Rinse with clean water repeatedly until the chloride ion content is lower than 0.1%. Use a ball mill to wet-grind to about 1000 meshes. The obtained grinding slurry will pass through a magnetic separator to remove free iron and then precipitate naturally. Then the sediment will be separated by mechanical means, and the sediment will be sent back to the wet grinding link to participate in grinding again. Add 6% (volume content) of Tween-80 to the suspension slurry that removes sediment, adopt 1.5KW high-energy ultrasonic dispersion for 2min, and obtain filter cake to suspension hydraulic filtration, and adopt supersonic speed grinding method to filter cake Grind to about 4000 mesh. Accelerate the sed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com