Method for self-assembling preparing colloidal photonic crystals and improving mechanical stability

A colloidal photonic crystal and colloidal crystal technology, which is applied in crystal growth, microsphere preparation, microcapsule preparation, etc., can solve the problems that colloidal photonic crystal films cannot meet the requirements, limit the application of three-dimensional colloidal photonic crystal films, and have limited mechanical stability. , to achieve the effect of improving the quality and scope of application, increasing mechanical stability, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Preparation of silica colloidal photonic crystal microspheres:

[0023] 1. Choose an aqueous solution of silica colloidal particles with a particle size of 200 nanometers, with a particle concentration of 10%;

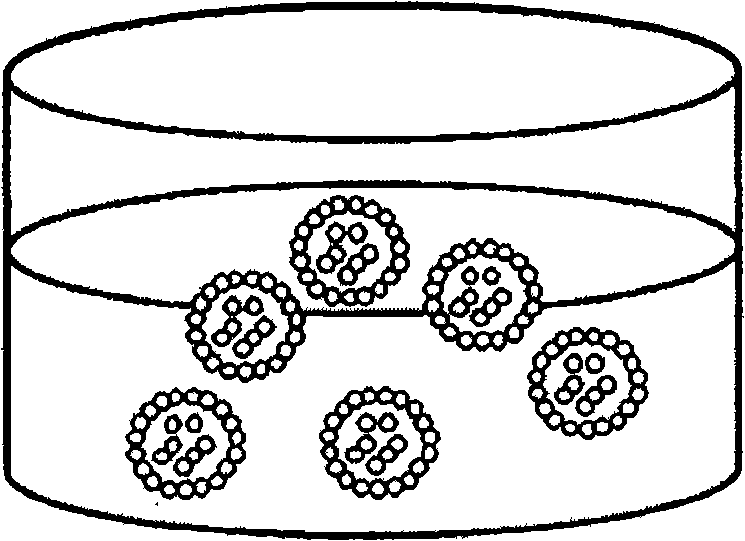

[0024] 2. Disperse the colloidal silica solution into silicone oil through the droplet generator to form droplets of the colloidal silica solution;

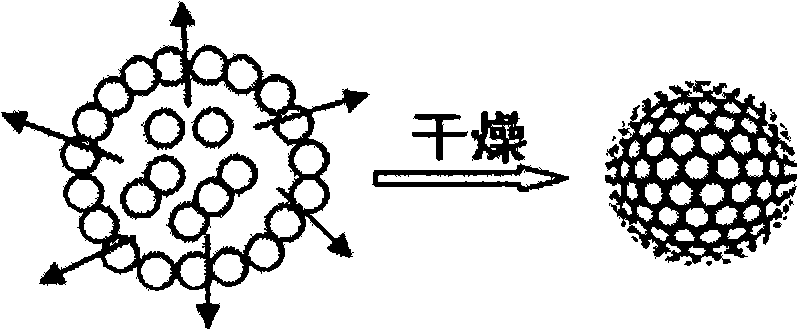

[0025] 3. Dry the droplets of the colloidal silica solution at 90°C to evaporate the water in them. The treatment time is 8 hours to obtain colloidal silica photonic crystal microspheres;

[0026] 4. Wash off the silicone oil on the surface of the colloidal photonic crystal microspheres, and then treat it at 1000°C for 2 hours to obtain colloidal photonic crystal microspheres with high mechanical stability.

Embodiment 2

[0027] Example 2: Preparation of polystyrene colloidal photonic crystal microspheres:

[0028] 1. Choose an aqueous solution of polystyrene colloidal particles with a particle size of 260 nm, with a particle concentration of 30%;

[0029]2. Disperse the polystyrene colloidal solution into the silicone oil through the droplet generator to form droplets of the polystyrene colloidal solution;

[0030] 3. Dry the droplets of the polystyrene colloidal solution at 60°C to evaporate the water in the droplets. The treatment time is 24 hours to obtain polystyrene colloidal photonic crystal microspheres;

[0031] 4. Wash off the silicone oil on the surface of the colloidal photonic crystal microspheres, and then treat it at 110°C for 2 hours to obtain colloidal photonic crystal microspheres with high mechanical stability.

Embodiment 3

[0032] Example 3: Preparation of polymethyl methacrylate colloidal photonic crystal microspheres:

[0033] 1. Choose an aqueous solution of polymethyl methacrylate colloidal particles with a particle size of 240 nanometers, with a particle concentration of 24%;

[0034] 2. Disperse the polymethyl methacrylate colloidal solution into silicone oil through the droplet generator to form droplets of the polymethyl methacrylate colloidal solution;

[0035] 3. Dry the droplets of the polymethyl methacrylate colloidal solution at 80°C to evaporate the water in the droplets. The treatment time is 12 hours to obtain polymethyl methacrylate colloidal photonic crystal microspheres;

[0036] 4. Wash off the silicone oil on the surface of the colloidal photonic crystal microspheres, and then treat it at 110°C for 2 hours to obtain colloidal photonic crystal microspheres with high mechanical stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com