Radiating, thermal insulating and decorating integrated composite plate

A composite panel and vacuum insulation panel technology, applied in covering/lining, building, building structure, etc., can solve the problems of uneven material quality of anti-radiation layer, unable to achieve satisfactory energy-saving effect, occupying building use space, etc. Easy size, light weight, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

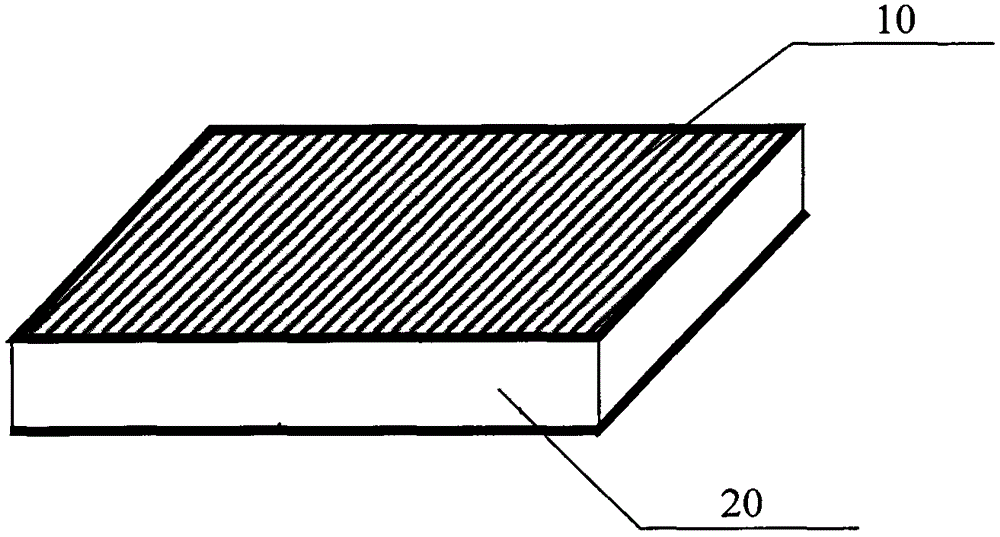

[0021] An integrated composite board for radiation heat preservation and decoration, which includes a vacuum insulation board and a surface layer, the surface layer is composed of 22 parts of titanium dioxide, carbon black powder, iron yellow powder and iron blue powder, 15 parts of hollow microspheres coated with aluminum, 20 parts SiO 2 Airgel, 40 parts of acrylic resin, 0.15 part of wetting agent, 0.3 part of dispersant, 0.3 part of defoamer, 0.04 part of preservative, 0.04 part of antifungal agent, 0.8 part of thickener, 1.9 part of film-forming aid and It is prepared with 0.08 parts of PH value regulator; the vacuum insulation panel is sealed in the surface layer by thermoplastic molding, the thickness of the surface layer is 10mm, and the panel surface bonded to the foundation wall is covered with high-strength alkali-resistant glass fiber cloth.

Embodiment 2

[0023] An integrated composite board for radiation heat preservation and decoration, which includes a vacuum insulation board and a surface layer, the surface layer is composed of 28 parts of titanium dioxide, 18 parts of hollow microspheres coated with aluminum on the surface, 15 parts of carbon airgel, 50 parts of epoxy resin, Prepared with 0.2 parts of wetting agent, 0.3 parts of dispersing agent, 0.3 parts of defoaming agent, 0.05 parts of preservative, 0.05 parts of antifungal agent, 0.5 parts of thickener, 1.5 parts of film-forming aid and 0.05 parts of pH regulator ;The vacuum insulation panel is sealed in the surface layer by thermoplastic molding, the thickness of the surface layer is 30mm, and the panel surface bonded to the base wall is covered with high-strength alkali-resistant glass fiber cloth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com