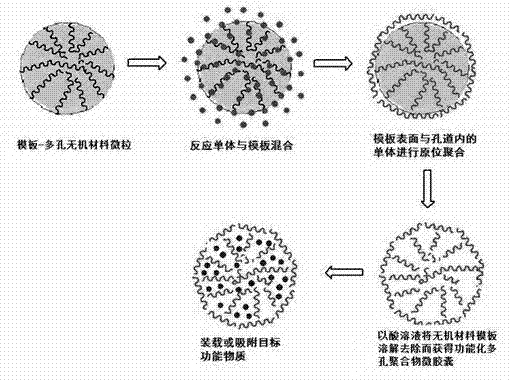

Porous functional microcapsule, preparation method and application

A functionalized, microcapsule technology, applied in microcapsule preparations, microsphere preparation, chemical instruments and methods, etc., can solve the problems of waste of raw materials, time-consuming, many steps, etc., and achieve easier size control, simple preparation process, and low price. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Porous functionalized microcapsules of polyacrylamide-co-styrene-co-methyl methacrylate copolymer

[0023] (1) Mix 85.7g of deionized water, 5mg of sodium polyacrylate, and 14.3g of porous calcium carbonate filter cake with a solid content of 35wt%, and fully disperse them to make a porous calcium carbonate water suspension with a solid content of 5wt% and good dispersibility liquid, spare;

[0024] (2) Stir the aqueous suspension of porous inorganic particles prepared in step (1) under nitrogen gas, control the speed at 300 r / min, add 5 g of acrylamide, raise the temperature to 60°, stir for 1 hour, and then add azobisiso Butyamidine hydrochloride 40mg and start timing, and dropwise add styrene 3g and methyl methacrylate 2g therein within 0.5h, keep warm at 60 ° of reaction 4h after dropwise addition, vacuum suction filter after the reaction solution is cooled, get filter cake for use;

[0025] (3) Add 0.1N hydrochloric acid solution dropwise to the filter...

Embodiment 2

[0026] Example 2: Porous functionalized microcapsules of polyacrylamide-co-dimethyldiallylammonium chloride-co-methyl methacrylate copolymer

[0027] (1) Mix 33.3g of deionized water, 60mg of sodium hexametaphosphate, and 66.7g of porous calcium carbonate filter cake with a solid content (that is, inorganic powder) of 30wt%, and fully disperse it to make a solid content of 20wt with good dispersion performance. % porous calcium carbonate aqueous suspension, set aside. In this embodiment, 66.7g solid content is that the pure calcium carbonate contained in the filter cake of 30wt% is 66.7g * 30%=20g, and water should be 66.7g-20g=44.7g, then the total amount of water in the system is 44.7+33.3=80g, at this time the ratio of deionized water: sodium hexametaphosphate: porous calcium carbonate should be 4:0.003:1.

[0028] (2) Stir the aqueous suspension of porous inorganic particles prepared in step (1) under nitrogen, control the speed at 1000 r / min, add 15 g of acrylamide and 5...

Embodiment 3

[0030] Example 3: Porous functionalized microcapsules of poly-N-isopropylacrylamide-co-dimethyldiallylammonium chloride-co-methyl methacrylate copolymer

[0031] (1) Mix 92g of deionized water, 80mg of sodium silicate, and 8g of porous aerosol silica, and fully disperse to prepare a porous aerosol silica aqueous suspension with a solid content of 8wt% and good dispersibility, and set aside;

[0032] (2) Stir the aqueous suspension of porous inorganic particles prepared in step (1) under nitrogen, control the speed at 600 r / min, add 6 g of N-isopropylacrylamide and dimethyl diallyl chloride Ammonium 2g, heat up to 40 °, after stirring for 1h, add 0.16g of azobisisobutylimidazoline hydrochloride and start timing, and add 16g of methyl methacrylate dropwise to it within 0.5h, keep the temperature after the dropwise addition React at 50° for 12 hours, vacuum filter after the reaction solution is cooled, and obtain a filter cake for later use;

[0033](3) Add 0.1N hydrofluoric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com