Process for producing flower shaped indium hydroxide powder having high specific surface area

A high specific surface area, indium hydroxide technology, applied in chemical instruments and methods, inorganic chemistry, gallium/indium/thallium compounds, etc., to achieve good application prospects, high specific surface area, and size controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

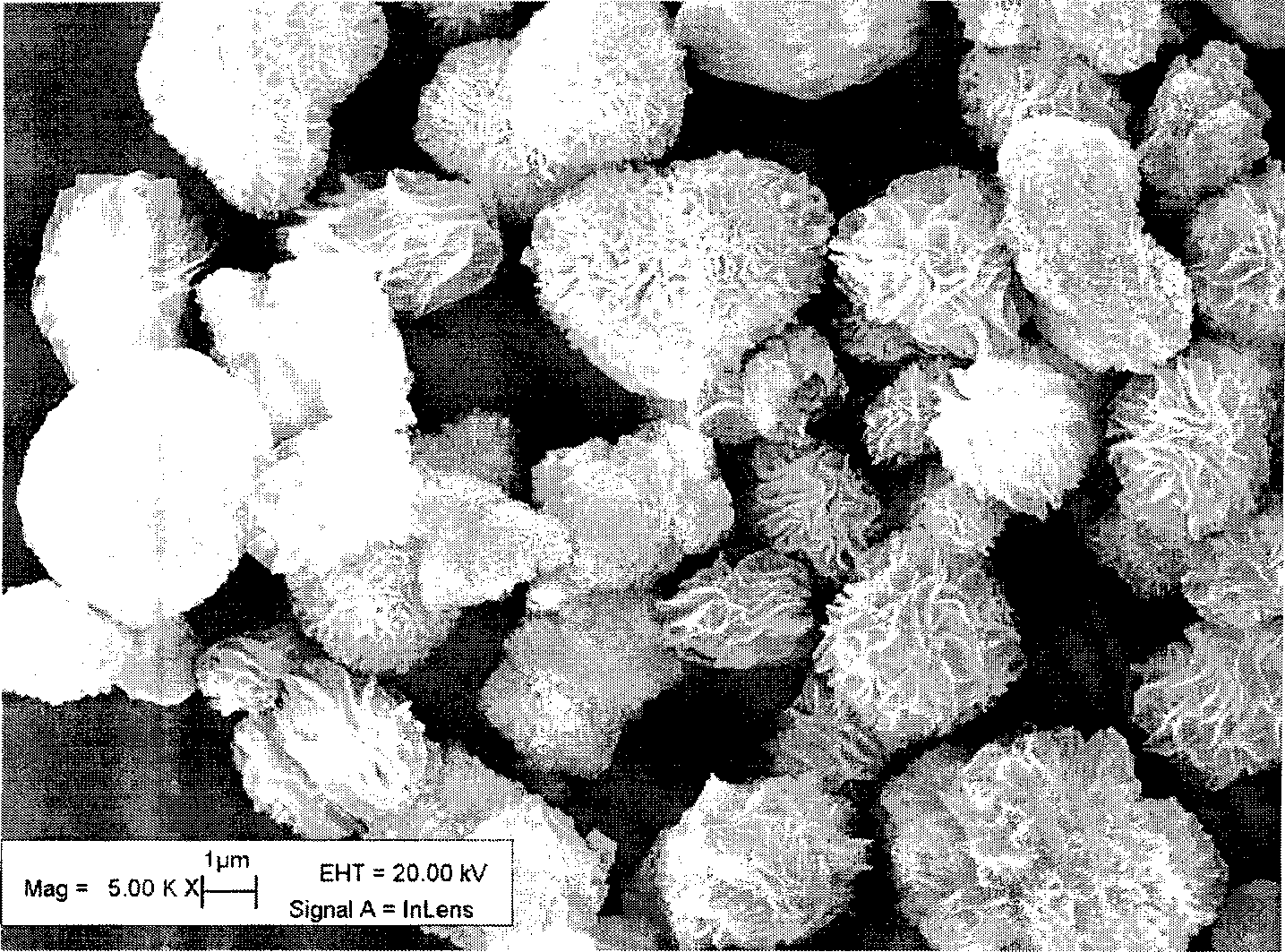

[0021] Prepare 80 mL of an aqueous solution of indium chloride inorganic salt with a molar concentration of 0.01 mol / L, add 0.0008 mol of surfactant sodium lauryl sulfate, and then add 0.004 mol of urea as an alkali source. After ultrasonic vibration for several minutes, the mixture was put into a 100mL stainless steel reaction kettle lined with polytetrafluoroethylene, sealed and then hydrothermally reacted at a low temperature of 90°C for 12h. Take it out, cool it down to room temperature, wash the precipitate obtained by filtration with a mixed solution of ethanol and water with a volume ratio of 1:1, centrifuge to precipitate, and dry at 80°C to obtain flower-shaped indium hydroxide powder. The obtained powder BET is 38m 2 / g, XRD diffraction shows that it is mainly oriented along the [100] direction, and the amount of InOOH is 8%. Such as figure 1 shown.

Embodiment 2

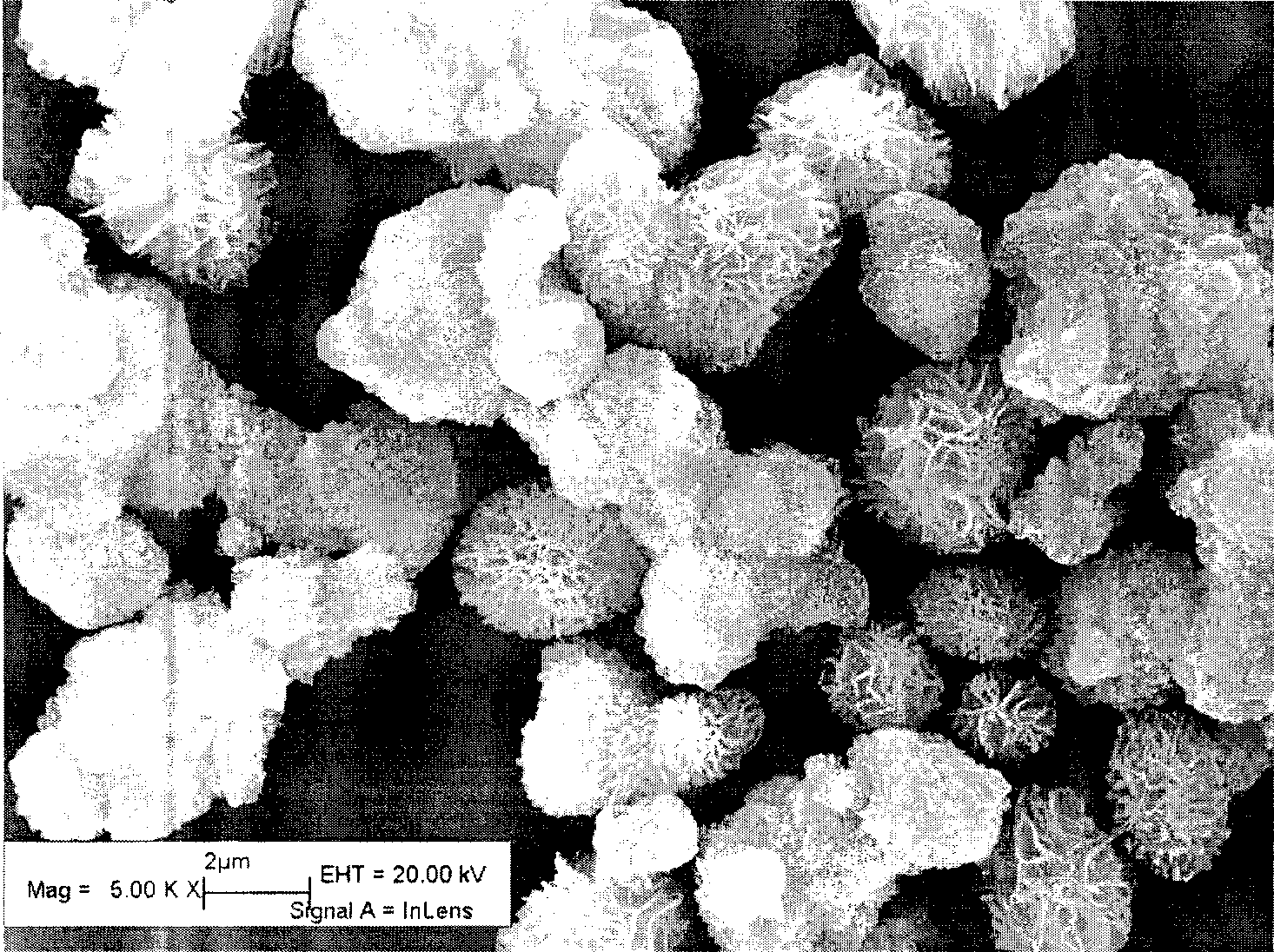

[0023] Prepare 80 mL of indium chloride aqueous solution with a molar concentration of 0.1 mol / L, add 0.008 mol of sodium lauryl sulfate and 0.048 mol of urea. The reaction temperature is 95°C, the reaction time is 18h, and the BET can be obtained as 31m 2 / g, flower-shaped indium hydroxide powder containing 10% InOOH. All the other are with embodiment 1. Such as figure 2 shown.

Embodiment 3

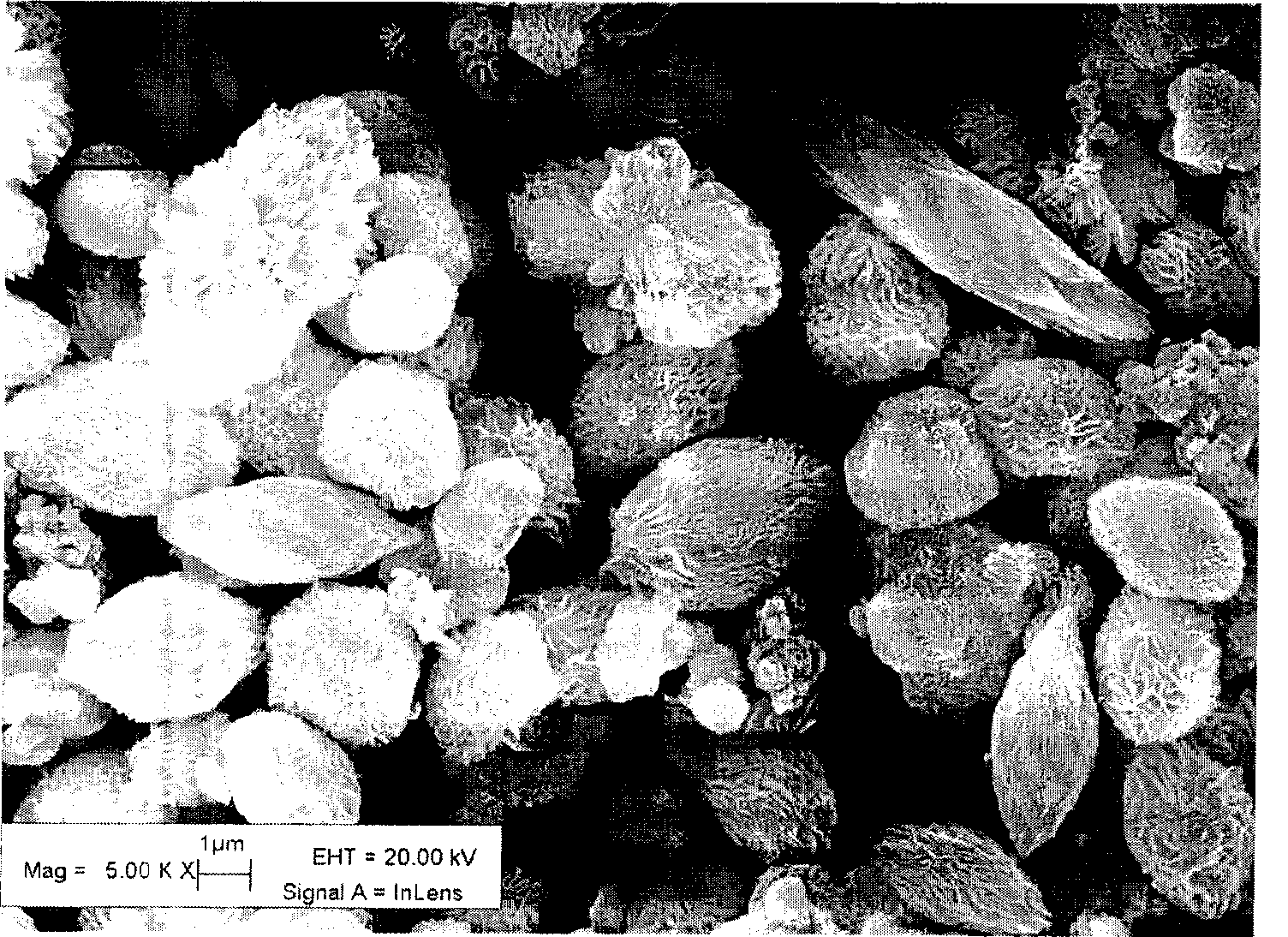

[0025] Prepare 80 mL of indium nitrate aqueous solution with a molar concentration of 0.2 mol / L, add 0.032 mol of sodium lauryl sulfate and 0.112 mol of urea. The reaction temperature is 105°C, the reaction time is 24h, and the BET can be obtained as 23m 2 / g, flower-shaped indium hydroxide powder containing 11% InOOH. All the other are with embodiment 1. Such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com