Method for rapidly preparing water-soluble quantum dot by ultrasonic spraying method

An ultrasonic spray, water-soluble technology, used in chemical instruments and methods, luminescent materials, etc., can solve problems such as limiting large-scale applications, and achieve the effect of large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Add cadmium nitrate and thioglycolic acid in sequence in deionized water, so that the molar ratio of cadmium nitrate and thioglycolic acid is 1:50. After the complexation reaction is completed, add sodium hydride telluride equimolar to cadmium nitrate to obtain water-soluble quantum point precursor solution, the final concentration of cadmium ion is 10 -5 M.

[0026] (2) Add the precursor solution obtained in step (1) to an ultrasonic atomizer. After ultrasonic atomization, the precursor solution exists in the form of submicron droplets to obtain the precursor solution of water-soluble quantum dots. mist.

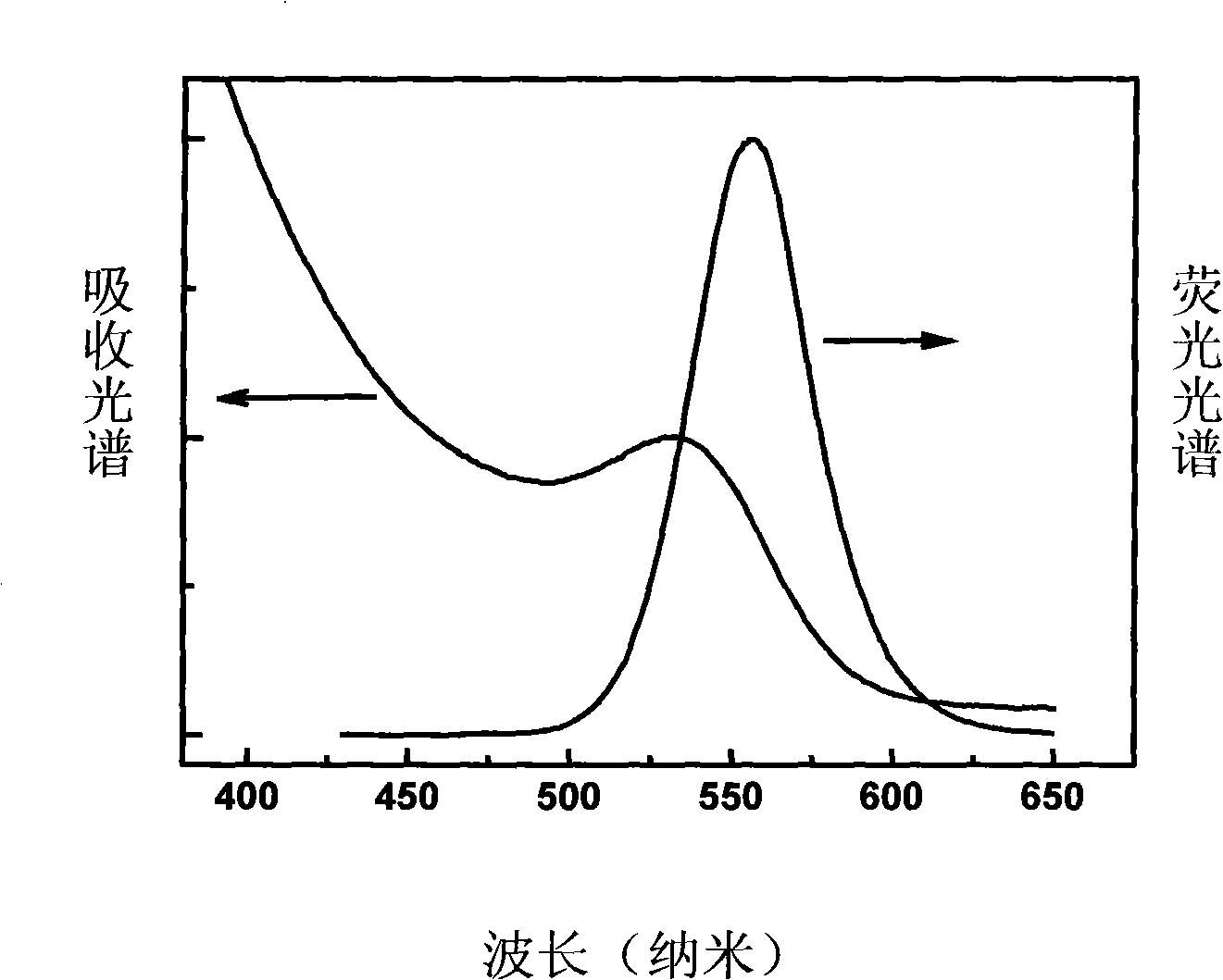

[0027] (3) Feed in nitrogen, the flow rate of nitrogen gas is 5L / min, and the droplets of the precursor solution obtained in step (2) are brought into the temperature-stabilized reaction device, and the droplets of the precursor solution are heated (the temperature is 450° C. ) reaction, and the reaction product is absorbed by water to obtain water-soluble cadm...

Embodiment 2

[0029] (1) Add cadmium nitrate and thioglycolic acid sequentially in deionized water, so that the molar ratio of cadmium nitrate and thioglycolic acid is 1:3. After the complexation reaction is completed, add sodium hydride telluride equivalent to cadmium nitrate to obtain water-soluble quantum point precursor solution, the final concentration of cadmium ions was 5×10 -2 M.

[0030] (2) Add the precursor solution obtained in step (1) to an ultrasonic atomizer. After ultrasonic atomization, the precursor solution exists in the form of submicron droplets to obtain the precursor solution of water-soluble quantum dots. mist.

[0031](3) Feed in nitrogen, the flow of nitrogen gas is 3L / min, and the droplets of the precursor solution obtained in step (2) are brought into the temperature-stabilized reaction device, and the droplets of the precursor solution are heated (the temperature is 250° C. ) reaction, and the reaction product is absorbed by water to obtain water-soluble cadmi...

Embodiment 3

[0033] (1) Add zinc acetate and thioglycolic acid in sequence in deionized water, so that the molar ratio of zinc acetate to thioglycolic acid is 1:20. After the complexation reaction is completed, add sodium hydride telluride equimolar to zinc acetate to obtain water-soluble quantum Dot precursor solution, the final concentration of zinc ions is 3×10 -2 M.

[0034] (2) Add the precursor solution obtained in step (1) to an ultrasonic atomizer. After ultrasonic atomization, the precursor solution exists in the form of submicron droplets to obtain the precursor solution of water-soluble quantum dots. mist.

[0035] (3) Feed in nitrogen, the flow rate of nitrogen gas is 1L / min, and the droplets of the precursor solution obtained in step (2) are brought into the temperature-stabilized reaction device, and the droplets of the precursor solution are heated (the temperature is 110° C. ) reaction, and the reaction product is absorbed by water to obtain water-soluble zinc telluride f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com