A preparing method of a platinum nanometer particle/titanium dioxide nanotube array, an electrode, a non-enzymatic glucose sensor and a composite material

A nanotube array and platinum nanoparticle technology, applied in the field of materials, can solve the problems of poor uniformity of the modified film layer, long time consumption, large amount of consumption, etc., and achieve the effects of improving photoelectric performance, improving catalytic ability and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

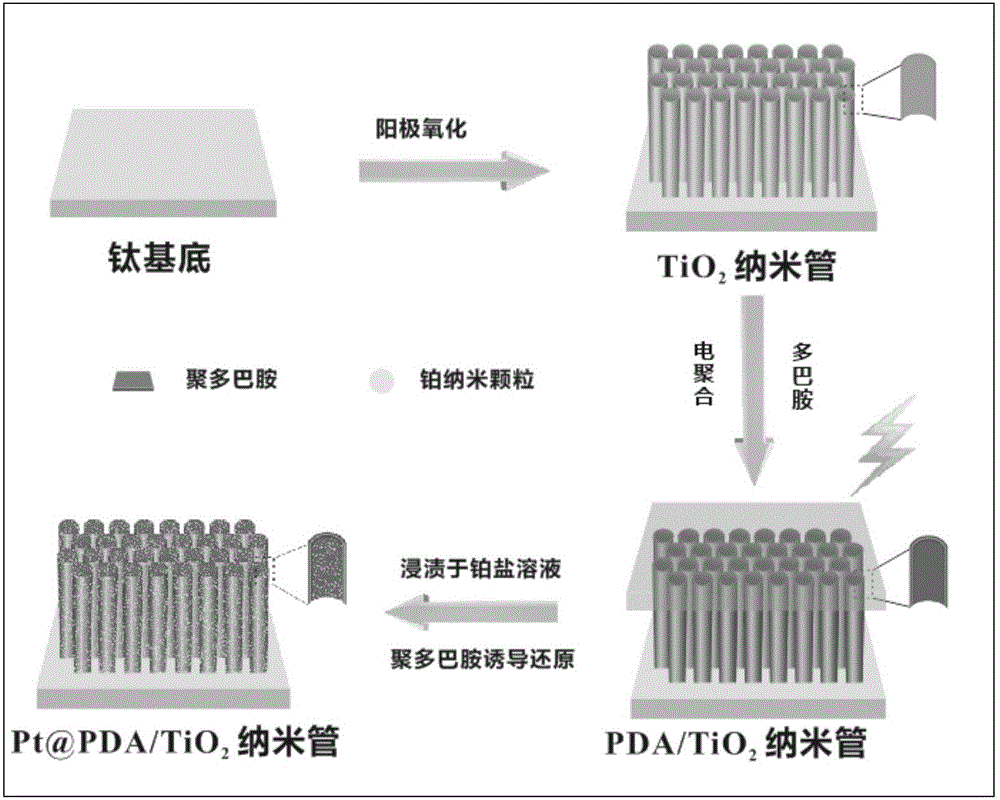

[0037] A method for preparing a platinum nanoparticle / titanium dioxide nanotube array, comprising:

[0038] S1. Titanium sheets can be used as the substrate, and the titanium sheets are pretreated first.

[0039] Specifically, the titanium sheet is cleaned. Wherein, the titanium sheet is pure titanium or titanium alloy, and its size is 1.5cm×3.0cm. Use dilute nitric acid, acetone, ethanol and deionized water to clean the titanium sheet ultrasonically for 20-40 minutes.

[0040] S2. Preparation of TiO by anodic oxidation 2 array of nanotubes.

[0041] Specifically, the cleaned titanium sheet is used as the anode, the platinum sheet is used as the cathode, and the ethylene glycol solution of ammonium fluoride and water is used as the electrolyte, a certain voltage is applied, and anodic oxidation is performed twice, and TiO is obtained by anodic oxidation. 2 Nanotube arrays, then calcined to obtain anatase TiO with better crystal form 2 array of nanotubes.

[0042] Wherein...

Embodiment 1

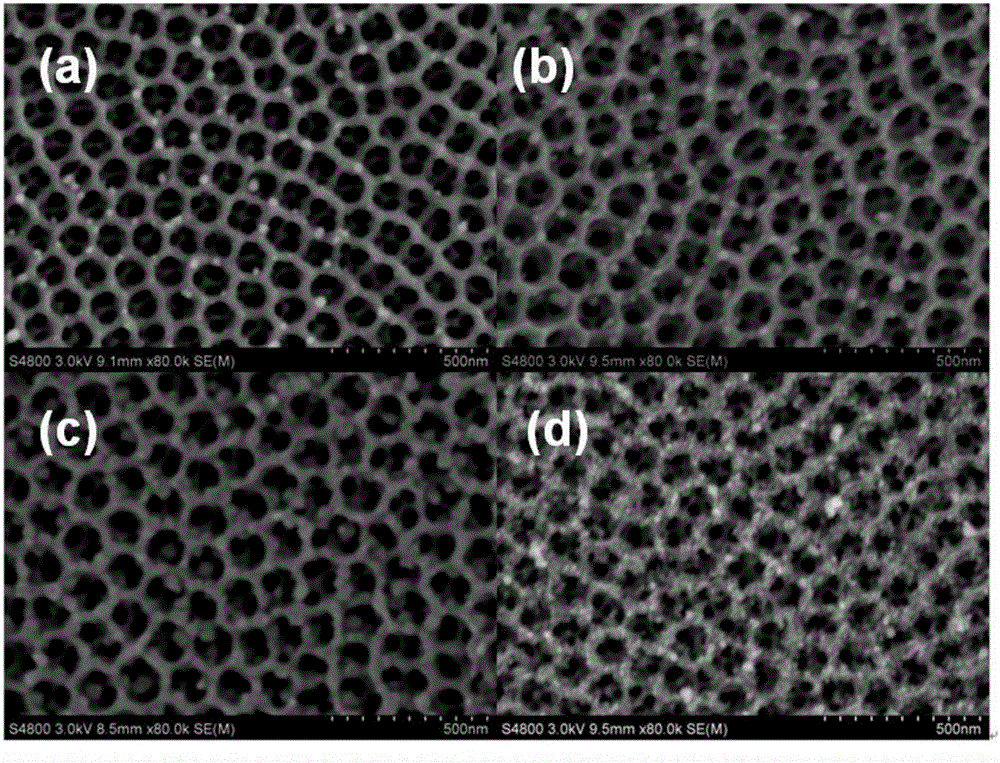

[0058] (1) Pretreatment of titanium sheet and preparation of TiO by secondary anodic oxidation 2 array of nanotubes. The pure titanium sheet substrate was ultrasonically cleaned with dilute nitric acid, acetone, absolute ethanol, and deionized water for 15 minutes in sequence. Use the platinum sheet electrode as the cathode, insert it into the electrolyte solution containing 98v% ethylene glycol (ammonium fluoride 0.3wt%) and 2v% water at the same time, apply a voltage of 40V for anodic oxidation for 1.5h, after the film layer is peeled off by ultrasonic, continue to apply a voltage of 40V Anodized for 8 minutes to produce TiO 2 The nanotube array was then calcined at 450°C for 2h to transform from amorphous state to anatase.

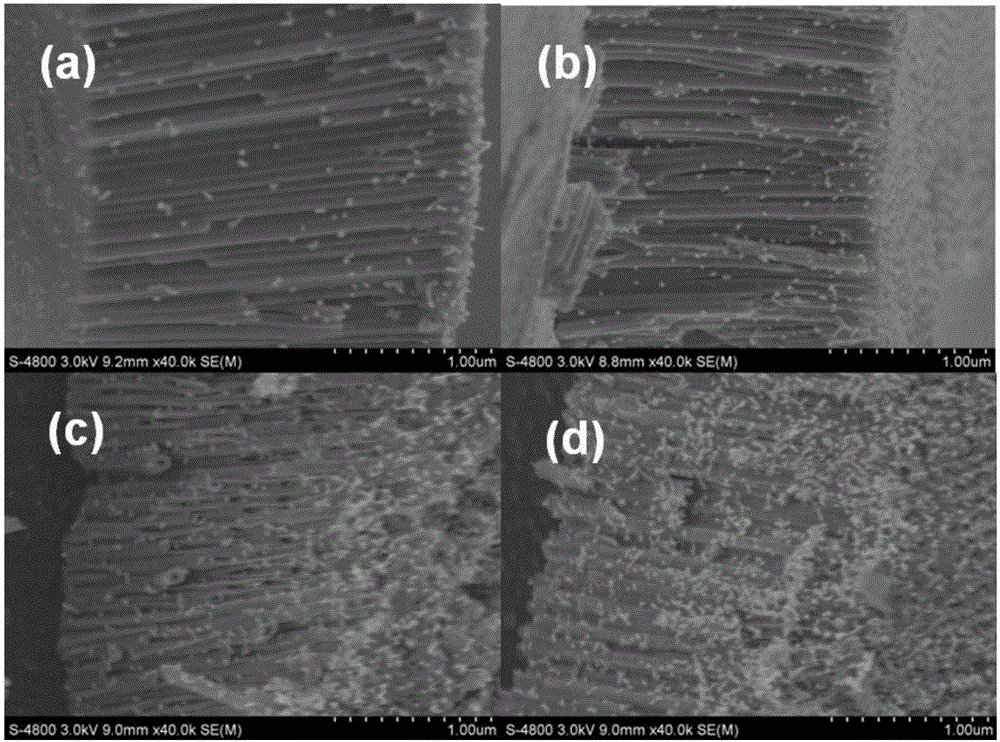

[0059] (2) A method of electropolymerizing polydopamine-induced reduction was used to prepare platinum nanoparticle-composite titania nanotube arrays. Prepare 50ml of 1.5mg / ml Tris, adjust the pH to 7.0, make a buffer solution, add 0.1g of dopamine h...

Embodiment 2

[0077] (1) Pretreatment of titanium sheet and preparation of TiO by secondary anodic oxidation 2 array of nanotubes. Clean the pure titanium substrate with dilute nitric acid, acetone, absolute ethanol, and deionized water for 10 minutes. Take the platinum sheet electrode as the cathode, insert it into the electrolyte solution containing 97v% ethylene glycol (ammonium fluoride 0.4wt%) and 3v% water at the same time, apply a voltage of 50V for anodic oxidation for 2h, after the film layer is peeled off by ultrasonic, continue to apply a voltage of 50V for the anode Oxidation for 6 minutes to produce TiO 2 The nanotube array was then calcined at 450°C for 1.5h to transform it from an amorphous state to anatase.

[0078] (2) A method of electropolymerizing polydopamine-induced reduction was used to prepare platinum nanoparticle-composite titania nanotube arrays. Prepare 50ml of 1.2mg / ml Tris, adjust the pH to 7.5, make a buffer solution, add 0.2g dopamine hydrochloride to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com