Double metal loaded sodium alginate/carboxymethylcellulose double-functional microballoon adsorbing material and preparation method thereof

A technology of carboxymethyl cellulose and sodium alginate, which is applied in the field of biomass resource utilization and biomass adsorption materials, can solve the problems of difficult separation of single-type ion adsorption powder adsorbents, single raw materials, difficult separation and recovery of powder adsorbents, etc. , to achieve the effect of good biodegradability, simple operation and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation method of bimetallic sodium alginate / carboxymethyl cellulose bifunctional microsphere adsorption material, comprising the following steps:

[0044] Step 1, dissolving sodium alginate and carboxymethyl cellulose into deionized water at a mass ratio of 19:1, mixing and stirring for 5 hours to obtain a composite sol with a concentration of 2 wt%.

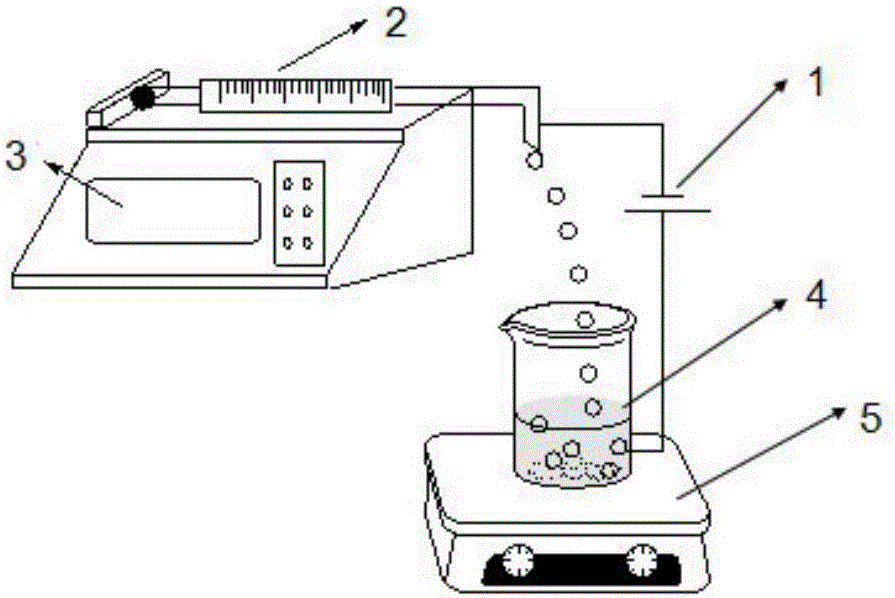

[0045] Step 2: Electrospray the composite sol into a receiving device containing a calcium chloride solution with a concentration of 5wt% by using an electrospray device, stir at a speed of 300r / min for 0.5h, and filter to obtain a gel microgel loaded with calcium ions. ball; the injection conditions of the electrospray device are: the ambient temperature is 40°C, the distance between the receiving device and the nozzle is 10cm, the flow rate is 20mL / h, the voltage is 3kV, and the stainless steel nozzle is No. 8 needle; the electrospray device Such as figure 1 As shown, it includes a high-voltage power supply 1, a...

Embodiment 2

[0048] A preparation method of bimetallic sodium alginate / carboxymethyl cellulose bifunctional microsphere adsorption material, comprising the following steps:

[0049] Step 1, dissolving sodium alginate and carboxymethyl cellulose into deionized water at a mass ratio of 9:1, mixing and stirring for 3 hours to obtain a composite sol with a concentration of 3wt%;

[0050] Step 2: Electrospray the composite sol into a receiving device containing a calcium chloride solution with a concentration of 8wt% by using an electrospray device, stir for 1 hour at a speed of 500 r / min, and filter to obtain gel microspheres loaded with calcium ions The injection conditions of the EFI device are: the ambient temperature is 30°C, the distance between the receiving device and the nozzle is 15cm, the flow rate is 30mL / h, the voltage is 5kV, and the stainless steel nozzle is a No. 6 needle;

[0051] Step 3: Place 8 g of the gel microspheres prepared in step 2 in parts by weight in a Soxhlet extra...

Embodiment 3

[0053] A preparation method of bimetallic sodium alginate / carboxymethyl cellulose bifunctional microsphere adsorption material, comprising the following steps:

[0054] Step 1, dissolving sodium alginate and carboxymethyl cellulose into deionized water at a mass ratio of 10:1, mixing and stirring for 6 hours to obtain a composite sol with a concentration of 2 wt%.

[0055] Step 2: Electrospray the composite sol into a receiving device containing a calcium chloride solution with a concentration of 12 wt% by using an electrospray device, stir for 1 hour at a speed of 100 r / min, and filter to obtain gel microspheres loaded with calcium ions The injection conditions of the EFI device are: the ambient temperature is 20°C, the distance between the receiving device and the nozzle is 20cm, the flow rate is 15mL / h, the voltage is 8kV, and the stainless steel nozzle is a No. 5 needle;

[0056] Step 3. Place 10 g of the gel microspheres prepared in step 2 in parts by weight in a Soxhlet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com