Nano-Pd magnetic catalyst, its preparation method, and its use in liquid phase catalysis reaction

A catalyst and magnetic technology, applied in the field of nano-magnetic catalysts, can solve problems such as complex processes, reduce separation costs and improve reuse efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

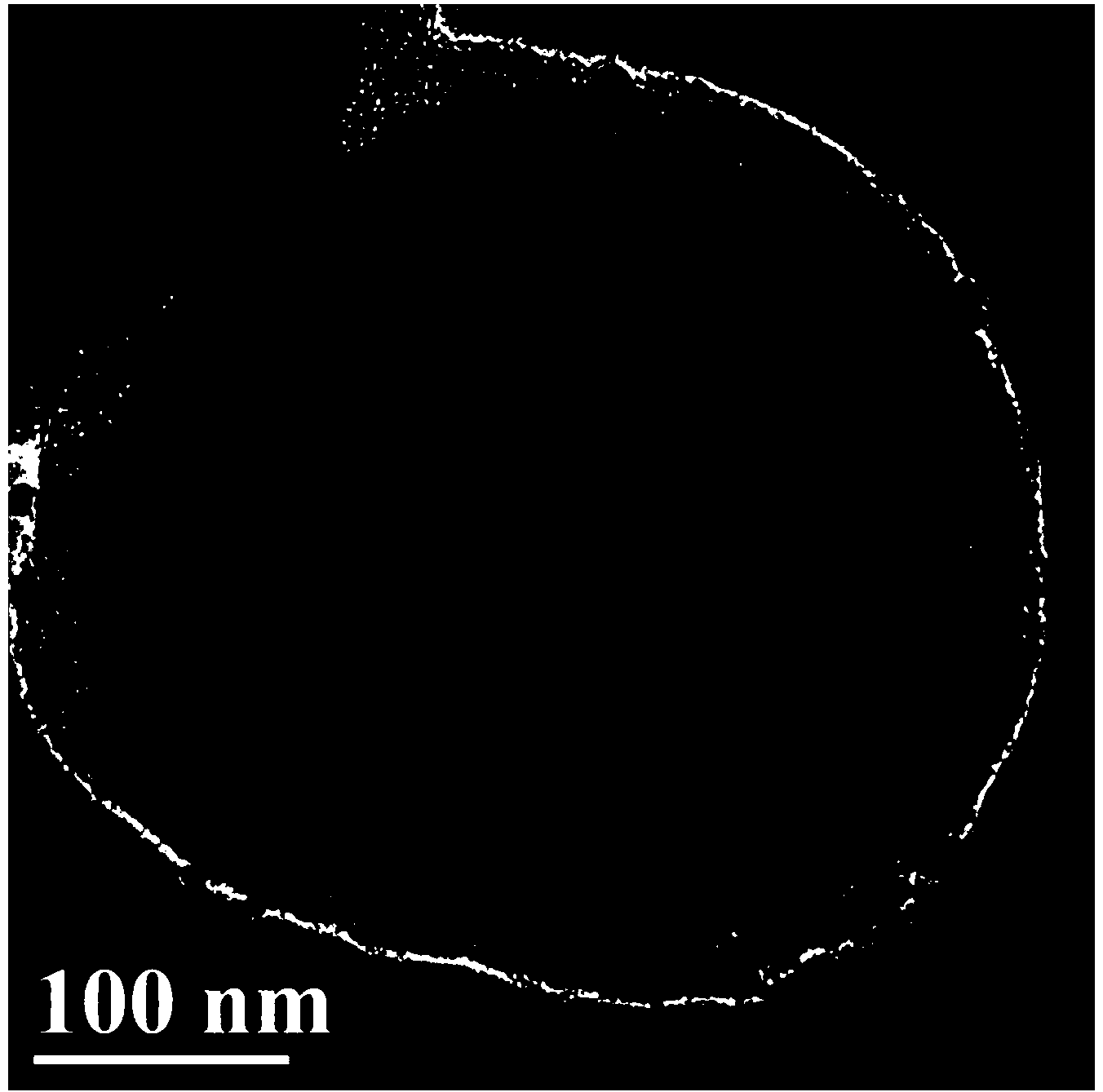

Image

Examples

Embodiment 1

[0020] (1) Weigh 13.4g FeCl 3 ·6H 2 O was dissolved in 86.6g of deionized water to make a solution, and 4.1g of sodium acetate was weighed and dissolved in 45.9g of ethylene glycol to make a solution. At the temperature of a water bath at 30°C and under stirring conditions, it was added dropwise to the solution containing N 2 In the protected reactor, after the dropwise addition, the mixed solution was put into an autoclave, crystallized at 180°C for 8 hours, then cooled naturally, washed with deionized water and ethanol three times, and dried in vacuum at 60°C for 8 hours. The obtained magnetic Fe 3 o 4 particles.

[0021] (2) Weigh the prepared magnetic Fe 3 o 4 Add 5.8g of granules to 44.2g of ethanol, add dropwise 20g of sodium silicate solution with a mass concentration of 5% and cetyltrimethyl bromide with a mass concentration of 0.2% at the same time at a water bath temperature of 30°C under stirring conditions Ammonium chloride (CTAB) ethanol solution 5g, after t...

Embodiment 2

[0025] (1) Weigh 20.3g FeCl 3 ·6H 2 O was dissolved in 79.7g of deionized water to make a solution, and 6.2g of sodium acetate was weighed and dissolved in 43.8g of ethylene glycol to make a solution. At the temperature of a water bath at 30°C and under stirring conditions, it was added dropwise to the solution containing N 2 In the protected reactor, after the dropwise addition, the mixed solution was put into an autoclave, crystallized at 180°C for 8 hours, then cooled naturally, washed with deionized water and ethanol three times, and dried in vacuum at 60°C for 8 hours. The obtained magnetic Fe 3 o 4 particles.

[0026] (2) Weigh the prepared magnetic Fe 3 o 4 Add 6.9g of granules to 43.1g of ethanol, add 20g of sodium silicate solution with a mass concentration of 10% and hexadecyltrimethyl bromide with a mass concentration of 0.2% at the same time under stirring conditions at a water bath temperature of 30°C Ammonium chloride (CTAB) ethanol solution 10g, after the ...

Embodiment 3

[0030] (1) Weigh 27.0g FeCl 3 ·6H 2 O was dissolved in 73.0g deionized water to make a solution, and 8.2g of sodium acetate was weighed and dissolved in 41.8g of ethylene glycol to make a solution, which was added dropwise at the temperature of a water bath at 30°C under stirring conditions 2 In the protected reactor, after the dropwise addition, the mixed solution was put into an autoclave, crystallized at 180°C for 8 hours, then cooled naturally, washed with deionized water and ethanol three times, and dried in vacuum at 60°C for 8 hours. The obtained magnetic Fe 3 o 4 particles.

[0031] (2) Weigh the prepared magnetic Fe3 o 4 Add 9.3g of granules to 40.7g of ethanol, add dropwise 15g of sodium silicate solution with a mass concentration of 15% and cetyltrimethyl bromide with a mass concentration of 0.2% at the same time at a water bath temperature of 30°C under stirring conditions Ammonium chloride (CTAB) ethanol solution 15g, after the dropwise addition, ammonia solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com