Magnetic nanosphere with mesoporous shell and quick preparation method thereof

A technology of magnetic nanospheres and nanospheres, applied in the field of magnetic nanospheres, can solve the problems of complex process of magnetic nanospheres, small specific surface area of magnetic nanospheres, long preparation time, etc. The effect of separating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

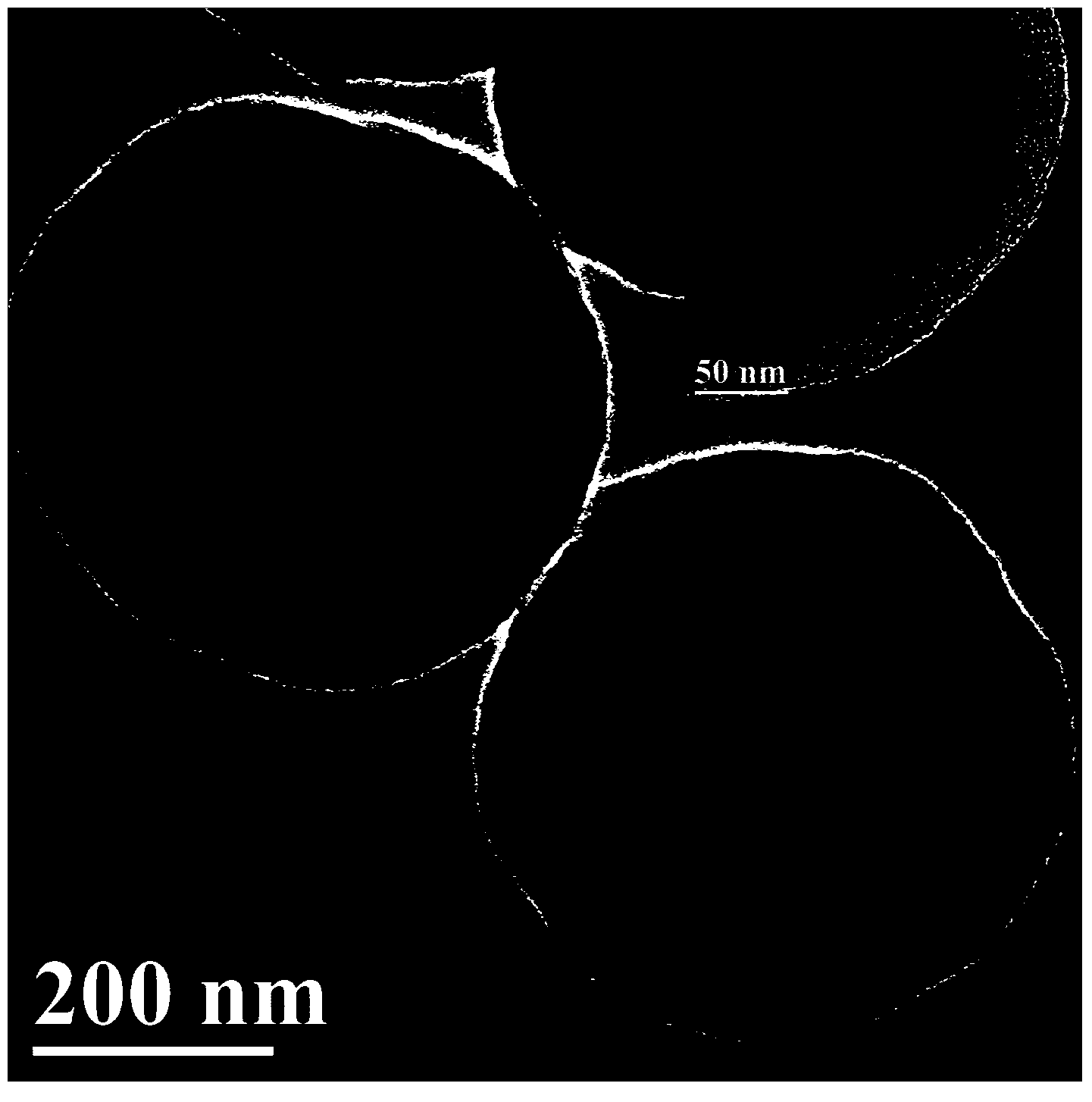

Image

Examples

Embodiment 1

[0018] (1) Weigh 13.4g FeCl 3 ·6H 2 O was dissolved in 86.6g of deionized water to make a solution, and 4.1g of sodium acetate was weighed and dissolved in 45.9g of ethylene glycol to make a solution. At the temperature of a water bath at 30°C and under stirring conditions, it was added dropwise to the solution containing N 2 In the protected reactor, after the dropwise addition, the mixed solution was put into an autoclave, crystallized at 180°C for 8 hours, then cooled naturally, washed with deionized water and ethanol three times, and dried in vacuum at 60°C for 8 hours. The obtained magnetic Fe 3 o 4 particles.

[0019] (2) Weigh the prepared magnetic Fe 3 o 4 Add 5.8g of granules to 44.2g of ethanol, add dropwise 20g of sodium silicate solution with a mass concentration of 5% and cetyltrimethyl bromide with a mass concentration of 0.2% at the same time at a water bath temperature of 30°C under stirring conditions Ammonium chloride (CTAB) ethanol solution 5g, after t...

Embodiment 2

[0021] (1) Weigh 20.3g FeCl 3 ·6H 2 O was dissolved in 79.7g of deionized water to make a solution, and 6.2g of sodium acetate was weighed and dissolved in 43.8g of ethylene glycol to make a solution. At the temperature of a water bath at 30°C and under stirring conditions, it was added dropwise to the solution containing N 2 In the protected reactor, after the dropwise addition, the mixed solution was put into an autoclave, crystallized at 180°C for 8 hours, then cooled naturally, washed with deionized water and ethanol three times, and dried in vacuum at 60°C for 8 hours. The obtained magnetic Fe 3 o 4 particles.

[0022] (2) Weigh the prepared magnetic Fe 3 o 4 Add 6.9g of granules to 43.1g of ethanol, add 20g of sodium silicate solution with a mass concentration of 10% and hexadecyltrimethyl bromide with a mass concentration of 0.2% at the same time under stirring conditions at a water bath temperature of 30°C Ammonium chloride (CTAB) ethanol solution 10g, after the ...

Embodiment 3

[0024] (1) Weigh 27.0g FeCl 3 ·6H 2 O was dissolved in 73.0g deionized water to make a solution, and 8.2g of sodium acetate was weighed and dissolved in 41.8g of ethylene glycol to make a solution, which was added dropwise at the temperature of a water bath at 30°C under stirring conditions 2 In the protected reactor, after the dropwise addition, the mixed solution was put into an autoclave, crystallized at 180°C for 8 hours, then cooled naturally, washed with deionized water and ethanol three times, and dried in vacuum at 60°C for 8 hours. The obtained magnetic Fe 3 o 4 particles.

[0025] (2) Weigh the prepared magnetic Fe 3 o 4 Add 9.3g of granules to 40.7g of ethanol, add dropwise 15g of sodium silicate solution with a mass concentration of 15% and cetyltrimethyl bromide with a mass concentration of 0.2% at the same time at a water bath temperature of 30°C under stirring conditions Ammonium chloride (CTAB) ethanol solution 15g, after the dropwise addition, ammonia so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com