Salt-containing wastewater treatment method

A technology for salty wastewater and concentrated water, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, ion-exchanged water/sewage treatment, etc. and other problems, to achieve the effect of short construction period, lower investment and investment saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

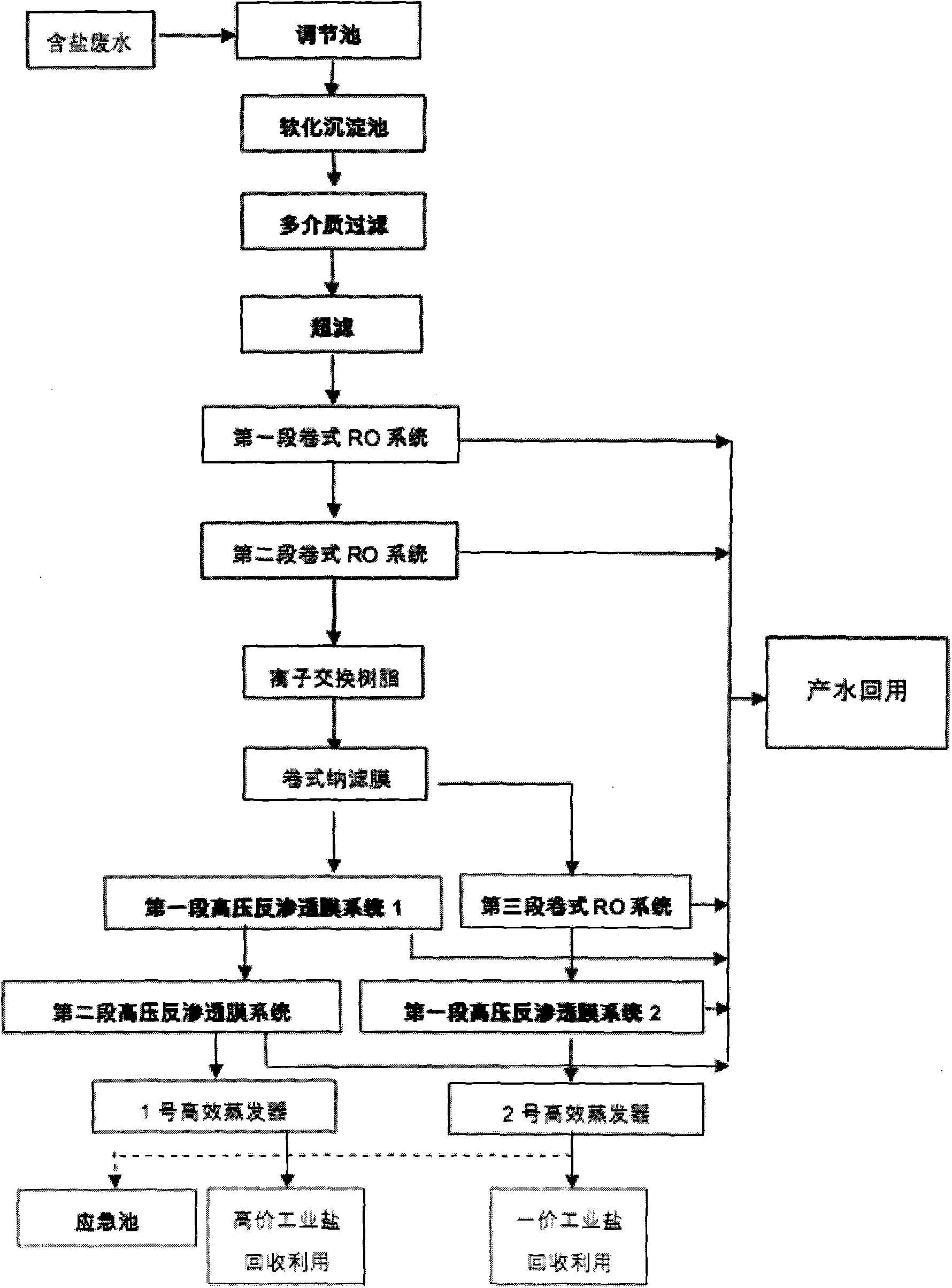

Image

Examples

Embodiment Construction

[0036] The following takes the industrial park saline wastewater treatment project as an example to introduce.

[0037] (1) The flow rate is 30000m 3 / d saline wastewater (TDS≤2800mg / L, hardness≤1600mg / L) enters the regulating tank through the pipeline for simple adjustment and then enters the softening sedimentation tank. First, add lime water to the softening sedimentation tank for 10 minutes of reaction, settle for 30 minutes, and then Add sodium carbonate, react for 10 minutes, precipitate for 30 minutes, then add acid to adjust the pH to 6.5, and the supernatant flows into the multi-media filter;

[0038] (2) The liquid flow initially filtered by the multi-media filter enters the ultrafiltration device through the high-pressure pump, and the liquid flow filtered by the ultrafiltration membrane device enters the first section of the roll-type reverse osmosis system through the high-pressure pump;

[0039] (3) Concentrated water production of the first section of the roll ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com