Novel energy-saving environment-friendly numerical-control fume hood of laboratory

An energy saving, environmental protection, fume hood technology, applied in the direction of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of airflow vortex, gas overflow, and airflow disorder in the work area, so as to avoid energy waste, avoid The effect of exhaust gas overflow and uniform surface wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

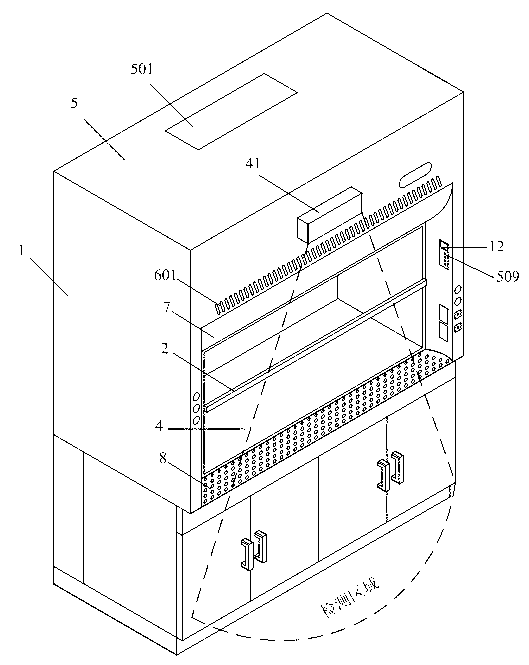

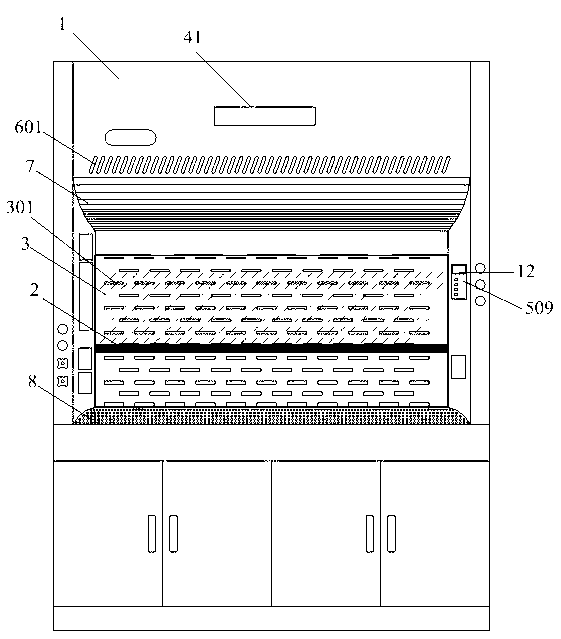

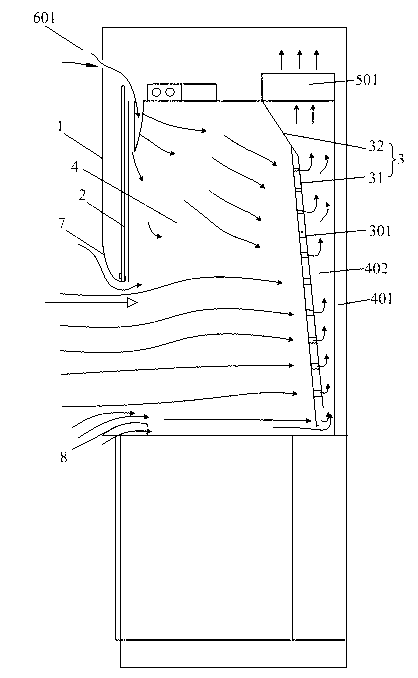

[0044] Embodiments of the present invention provide a novel energy-saving and environmental protection laboratory numerical control fume hood, such as Figure 1~3 As shown, it includes a cabinet body 1, a sliding window 2 and a deflector 3, and the sliding window 2 is arranged on the cabinet body to isolate the inside and outside of the cabinet body 1. The inner cavity 4 of the cabinet 1 constitutes the experimental work area (generally, the inner cavity of the cabinet 1 is provided with an experimental table). The deflector 3 is arranged in the inner cavity 4 of the cabinet 1 and is close to the inner wall 401 of the cabinet opposite to the sliding window 2, and an exhaust gas is formed between the deflector 3 and the inner wall 401 of the cabinet. Channel 402. The top 5 of the cabinet is provided with an air outlet 501 communicating with the exhaust channel 402, and the air outlet 501 is connected to an exhaust pipe to discharge the gas in the fume hood to the outside.

[...

Embodiment 2

[0054] refer to Figure 4 , the new energy-saving and environmental protection laboratory numerical control fume hood of the present embodiment, on the basis of embodiment 1, also comprises numerical control system 110, and described numerical control system 110 comprises sliding window automatic control device 111, non-contact sliding window control device 112, The surface wind speed control device 113 and the system control device 114, the sliding window automatic control device 110 is used to detect the presence / absence of an operator in the operating area in front of the fume hood and automatically control the increase / decrease of the opening of the sliding window. The non-contact sliding window control device 112 is used for the operator to open the sliding window to a desired position without contact. The face velocity control device 113 is used to automatically adjust the exhaust air volume of the fume hood according to the opening of the sliding window to maintain the ...

Embodiment 3

[0060] The embodiment of the present invention provides a surface wind speed adjustment device 113, such as Figure 5 As shown, the surface wind speed adjusting device comprises a displacement sensor 11 used to measure the opening of the sliding window of the fume hood, a controller 12 connected with the displacement sensor, and an exhaust air exhaust pipe 101 sequentially arranged on the fume hood. Fan 13 and variable air volume Venturi valve 15 , the air outlet of the variable air volume Venturi valve 16 is connected to the air inlet of the exhaust fan 13 , and the variable air volume Venturi valve 16 is connected to the controller 12 .

[0061] Specifically, combine figure 2 and Figure 4 , one end of the exhaust pipe 101 (ie Figure 5 A terminal in the fume hood) is connected to the exhaust outlet 51 of the fume hood, and the gas in the fume hood is discharged outside through the exhaust pipe 101 (ie Figure 4 in the B terminal). The gas in the fume hood enters the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com