Multi-ventilated-case cooperating exhaust control system

A control system and fume hood technology, applied in the direction of smoke removal, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of low control accuracy and difficulty in stabilizing the wind speed of the fume hood surface, so as to achieve reliable control and improve wind speed control Accuracy, intelligent saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution for applying the present invention will be further described in detail below in conjunction with the accompanying drawings.

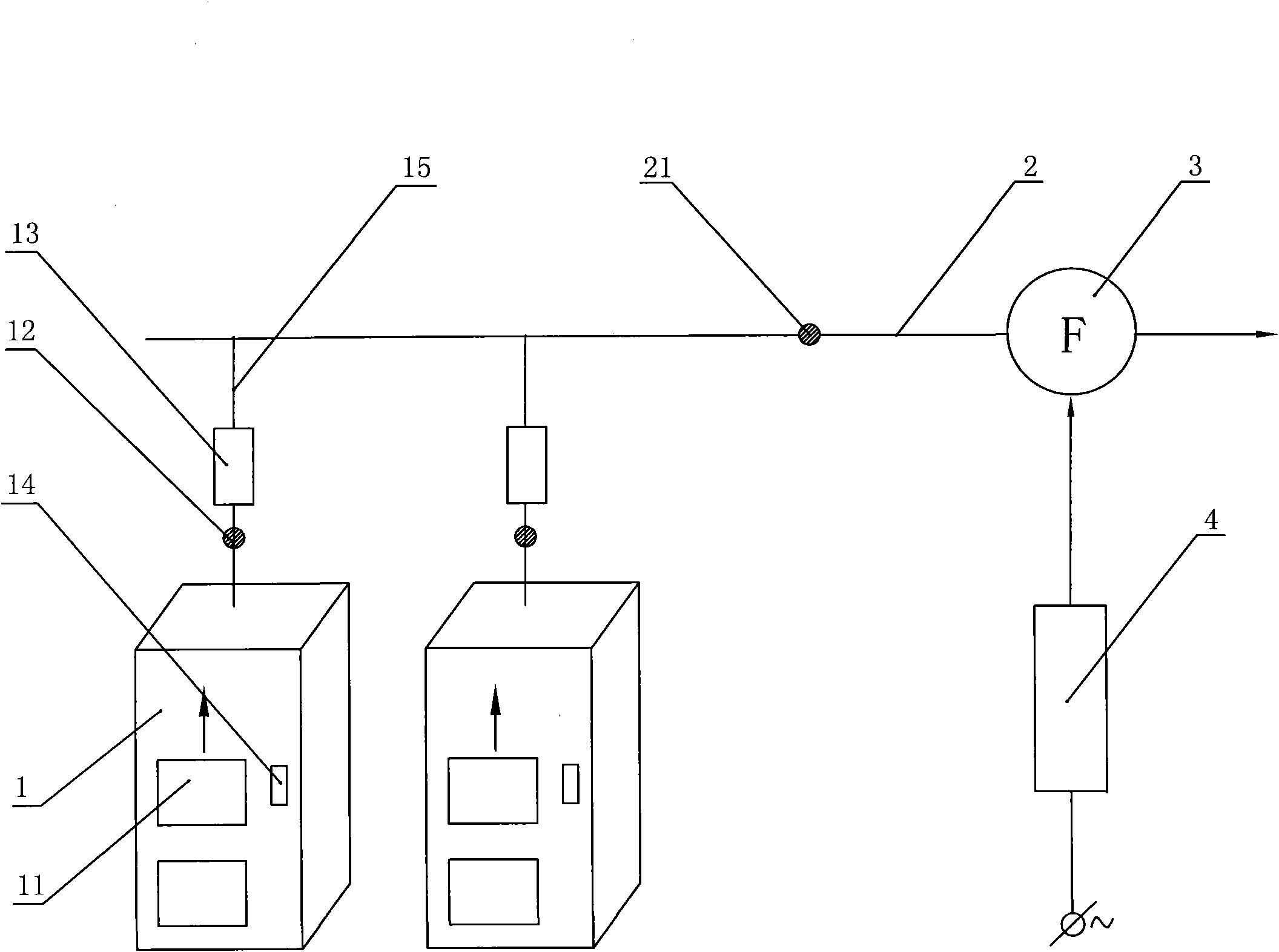

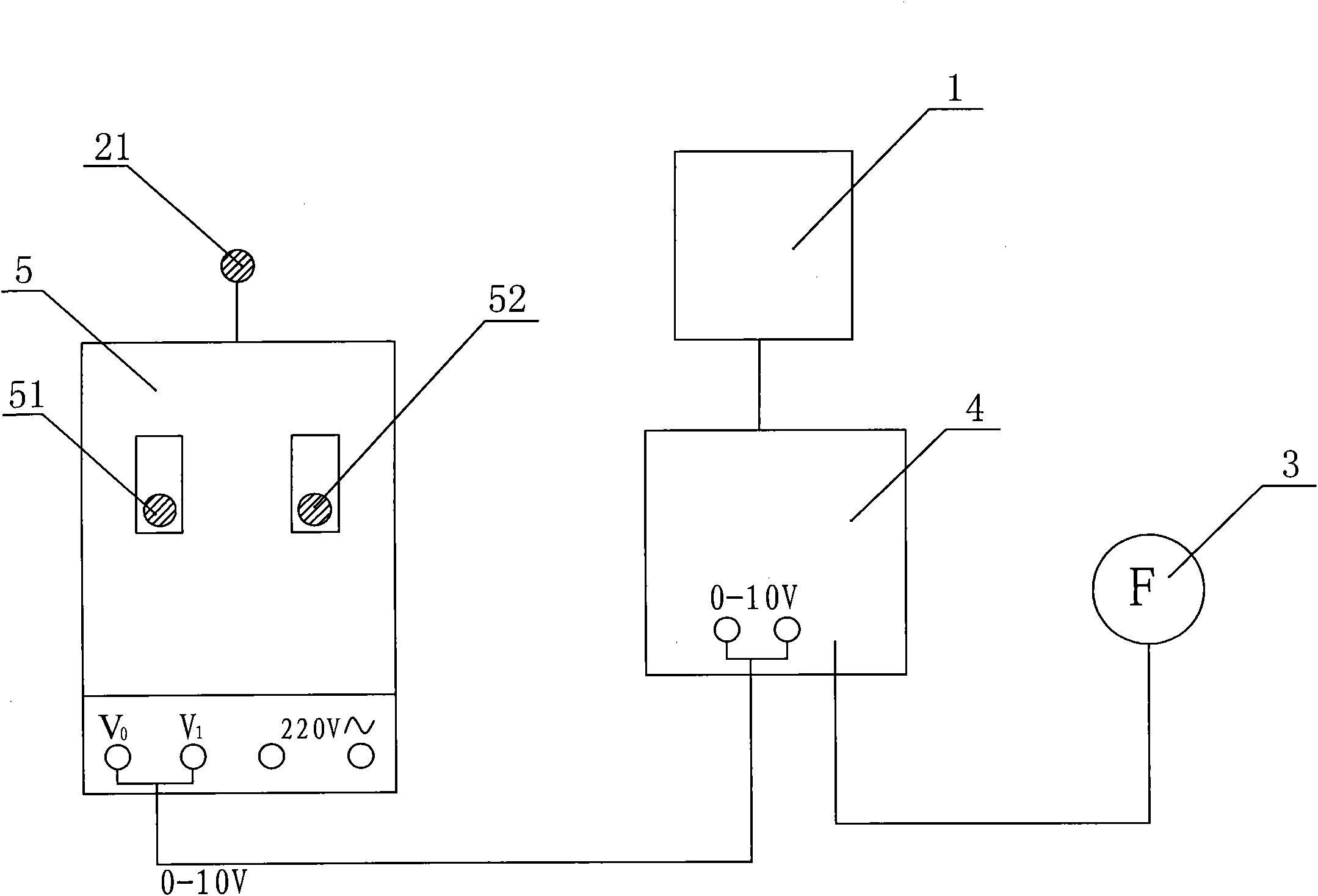

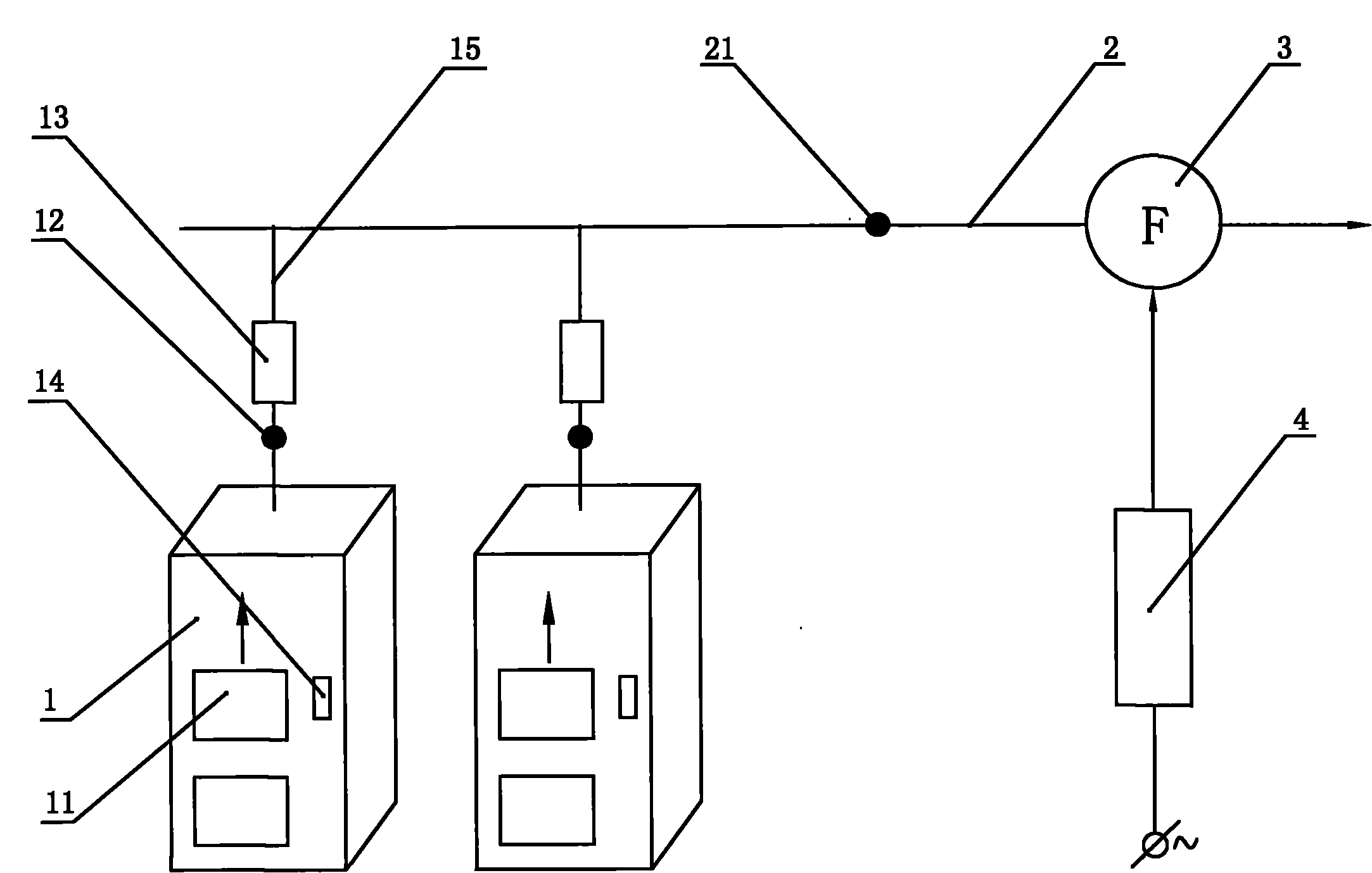

[0020] Such as figure 1 and figure 2 As shown, a ventilation control system of a fume hood includes more than 2 fume hoods 1, a main ventilation duct 2 and an exhaust fan 3 arranged on the main ventilation duct 2; secondly, on the main ventilation duct 2 and located A first differential pressure sensor 21 is arranged in front of the exhaust fan 3 . The first differential pressure sensor 21 mainly senses and detects the wind pressure in the main ventilation duct 2 . The exhaust fan 3 works under the drag of the frequency converter 4 . The installation method of the first differential pressure sensor 21 can be adaptively adjusted according to its structure.

[0021] Described fume hood 1 comprises cabinet body, and the front of described cabinet body is provided with cabinet door 11, and test bench is provided with in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com