Converter coal gas dry-method bag-type dust collecting and waste heat recovery method

A technology of converter gas and bag dust removal, which is applied in the direction of manufacturing converters, improving process efficiency, and improving energy efficiency. It can solve the problems of heavy equipment maintenance workload and unstable smoke and dust emission concentration, and save investment and land occupation. , stable dust removal effect and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

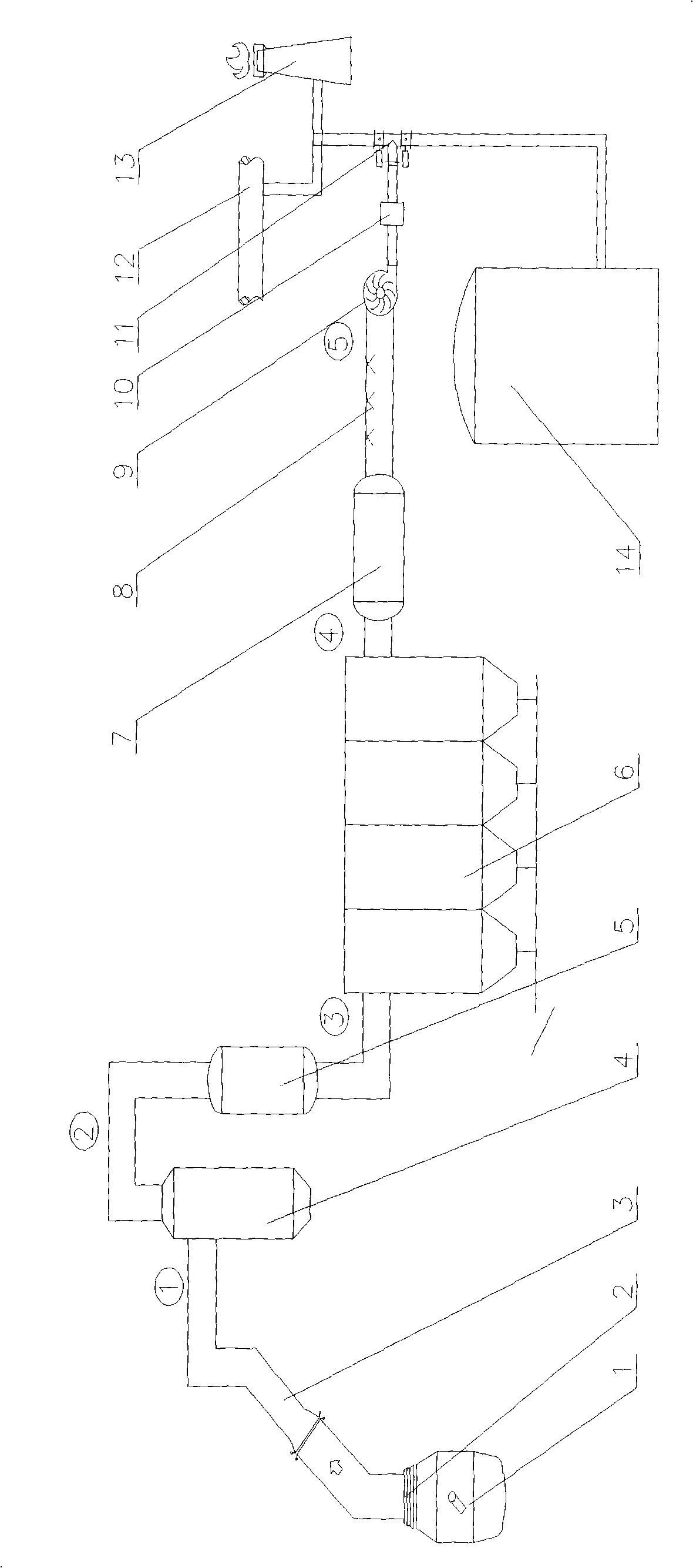

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following specific methods.

[0026] The movable fume hood 2 on the upper part of the converter 1 is connected to the vaporization cooling flue 3, and then connected to the coarse dust removal facility 4, the first-stage heat exchanger 5, the dry bag dust removal facility 6, the second-stage heat exchanger 7, and the spray cooling device 8 , frequency conversion speed regulating blower fan 9 and gas automatic analysis device 10 are respectively connected to blast furnace gas pipeline 12, combustion and diffusion tower 13 and gas cabinet 14 through three-way valve 11.

[0027] The dust collected by the dry bag dust removal facility 6 is collected and recycled by a pneumatic conveying device.

[0028] Converter gas dry bag dust removal and waste heat recovery methods are as follows:

[0029] 1) Dust-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com