An installation method for a main air-discharge pipe of a sintering machine

A technology for exhaust pipes and installation methods, which is applied in the direction of furnace types, furnaces, and charging treatment types, etc., which can solve problems such as difficult installation of pipes and large diameters, and achieve the effects of simple methods, improved utilization, and simple and fast methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A method for installing the main exhaust duct of a sintering machine, which includes the following steps:

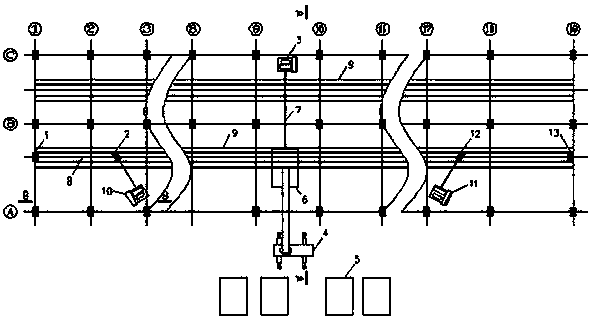

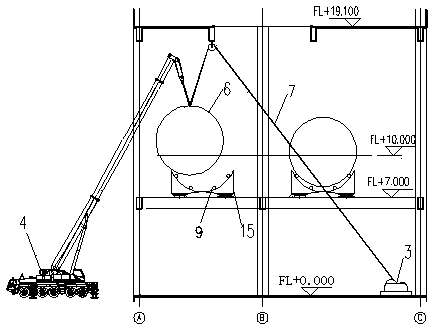

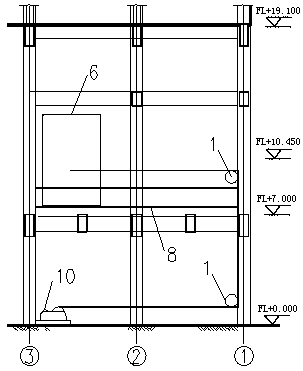

[0022] Such as Figure 1-3 As shown: the main exhaust duct is arranged in the sintering main plant building 1-19 columns, between the A-B spans and between the 1-19 columns B-C spans, here only describes the installation of the pipes between the A-B spans, and the installation steps are as follows:

[0023] The main exhaust duct is prefabricated by the factory. Since it is 128m long, it needs to be manufactured in sections. figure 1 The hoisting entrance shown is set between 9-10 columns with a spacing of 8m wide. At the same time, the butt weld of the pipe section needs to stagger the position of the pipe support;

[0024] Step 1: Check the activity of the main exhaust duct, the installation elevation and levelness of the fixed support, and perform secondary grouting after meeting the accuracy requirements. The seat and the base steel plate are welded and fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com