Precise positioning frame for large steel columns and equipment foundation fixing bolts and construction method of precise positioning frame

A technology for fixing bolts and equipment foundations, applied in the field of positioning frames, can solve problems such as inaccurate positioning, achieve accurate installation, speed up construction progress, and save construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

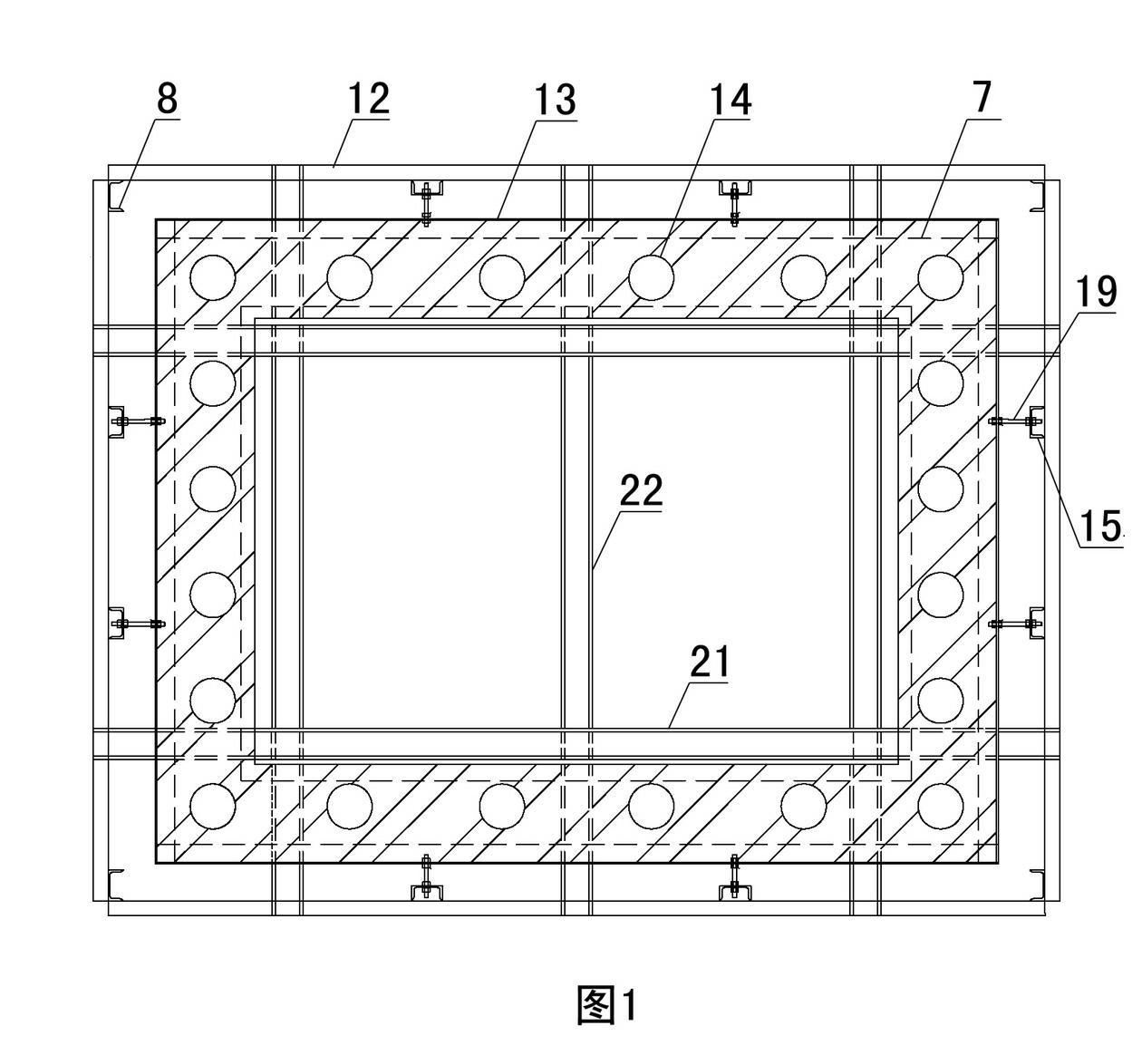

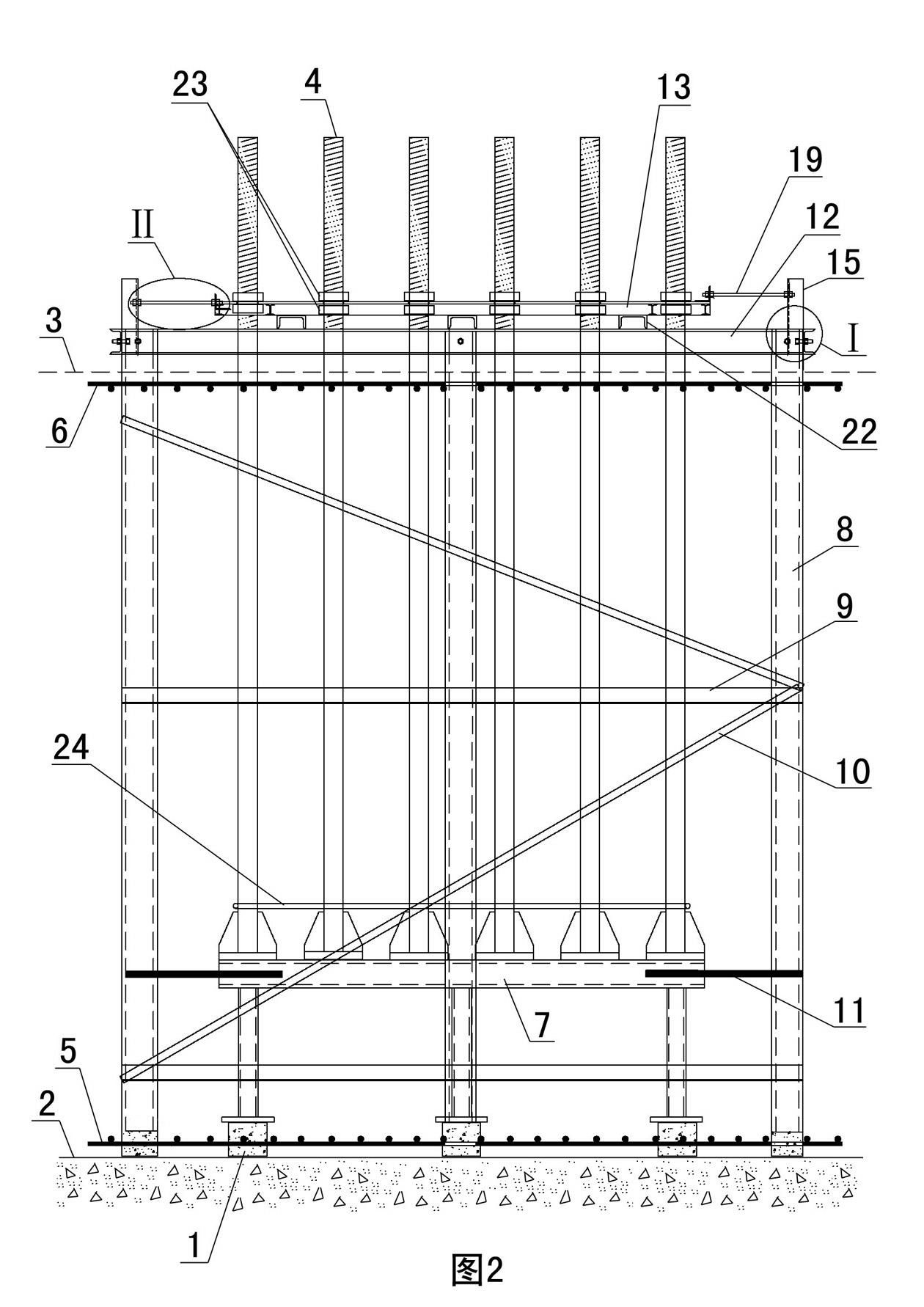

[0032] Examples see Figure 1-6 As shown, this large-scale steel column and equipment foundation fixing bolt precise positioning frame includes a support frame 7 for placing the fixing bolt 4, and the support frame 7 is placed on the cushion 2 through the concrete pad 1.

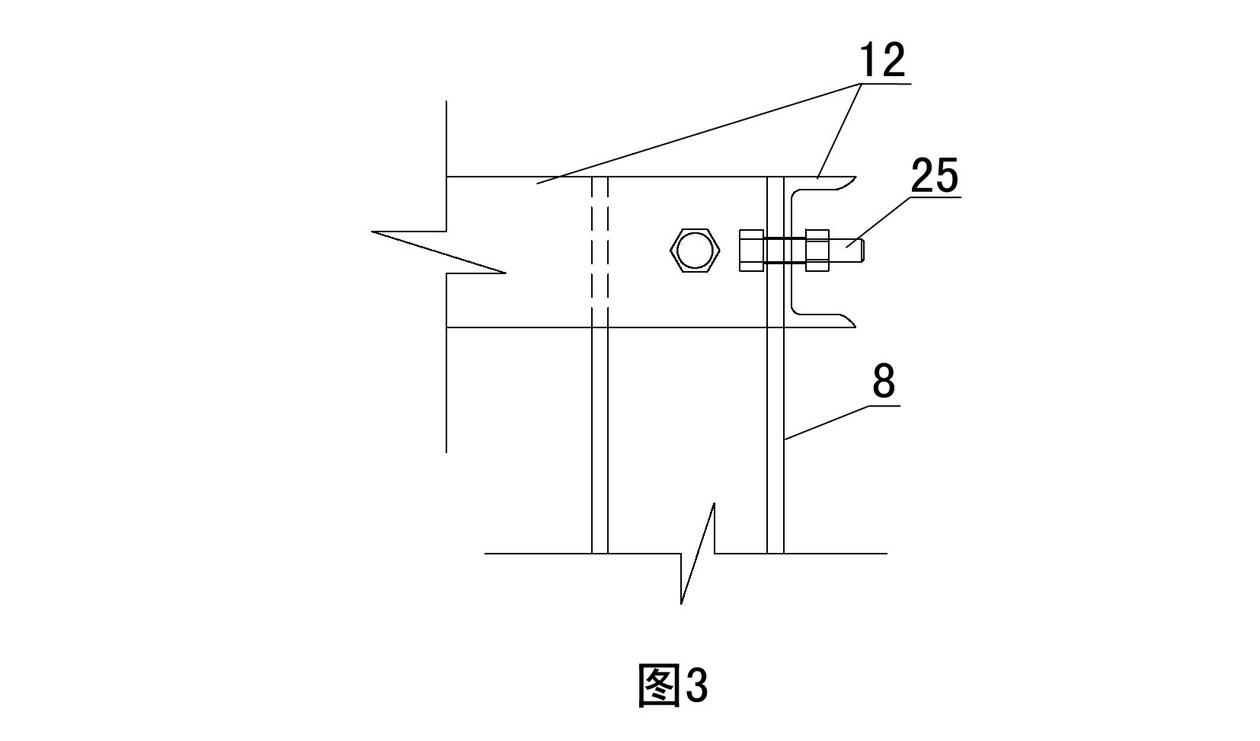

[0033] The outer side of the support frame 7 is surrounded by a shaped steel bracket, which includes uprights 8 distributed at intervals and connecting rods connected between two adjacent uprights 8 (connecting rods are horizontal bars 10 and / or oblique connecting rods 11) , the profiled steel bracket top frame 12 that is detachably connected between the upper ends of the vertical rods 8 by connecting bolts 25, and the positioning sleeve frame that is connected to the profiled steel bracket top frame 12 to set up the platform (the positioning sleeve frame is erected by cross-connected The lower end of the vertical rod 8 is also placed on the cushion layer 2 through the concrete pad 1, and the vertical rod 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com