High-rise building frame supported sectional steel concrete girder-like structural transfer floor construction method

A technology of structural transfer layer and construction method, which is applied in the direction of building structure and construction, can solve the problems of difficulty in reinforcement and difficulty in tying steel bars, and achieves the effects of good integrity, avoiding difficulty in welding construction, and enhancing earthquake resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

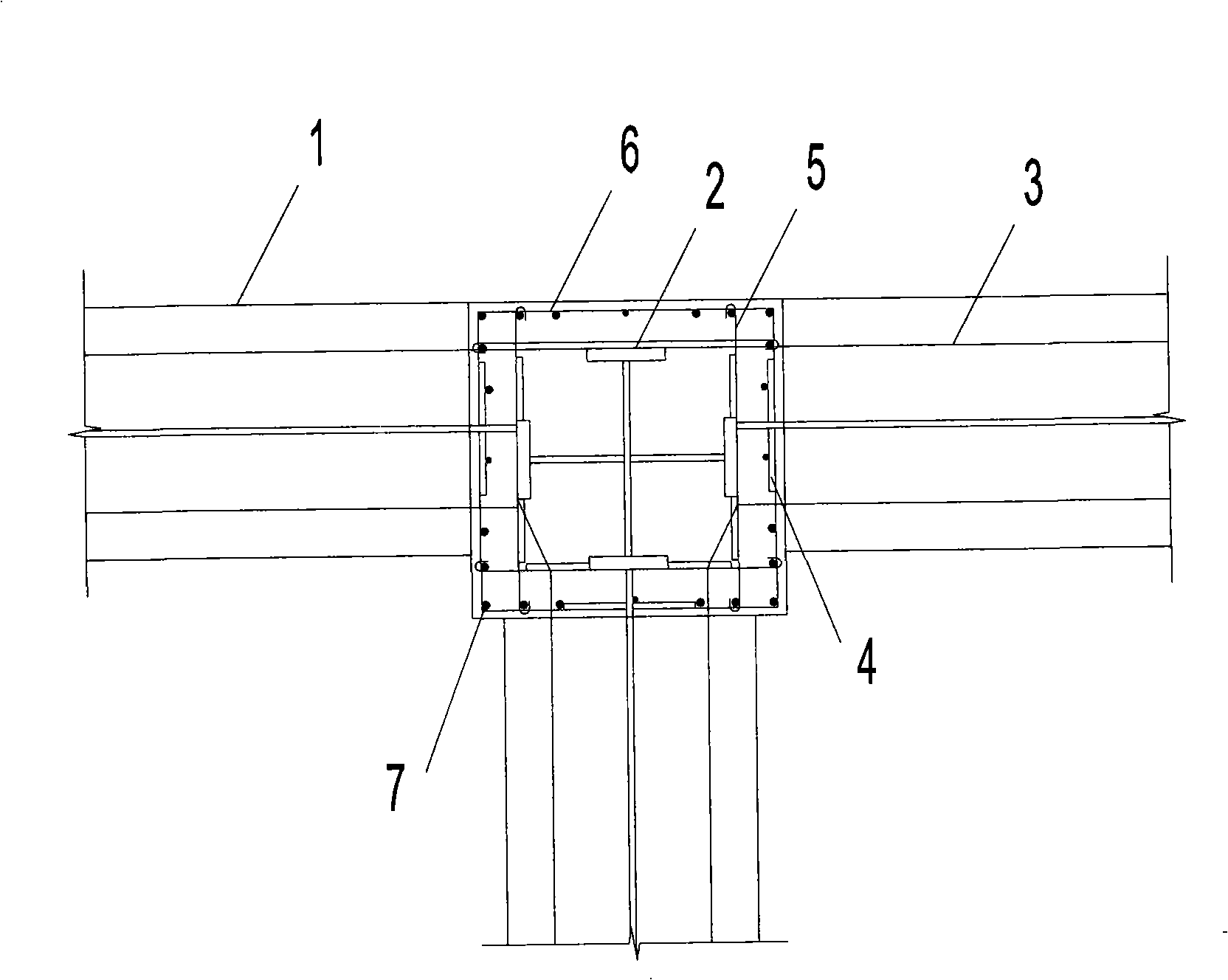

[0029] exist figure 1 Among them, the steel beam 3 in the steel concrete beam 1 and the steel column 2 flange plate are welded with the stiffener 4, the inner stirrup 5 of the steel column and the outer stirrup 6 of the steel column are made into open stirrups and welded on the stiffener 4 on. The double-sided welding is 5d, the weld thickness h is 0.4d, and the weld width b is 0.8d (d is the diameter of the steel bar). The welding quality must meet the acceptance and specification requirements. The inner side stirrup 5 of the shaped steel column and the other end of the outer stirrup 6 of the shaped steel column are bound with the main reinforcement 7 of the shaped steel concrete column.

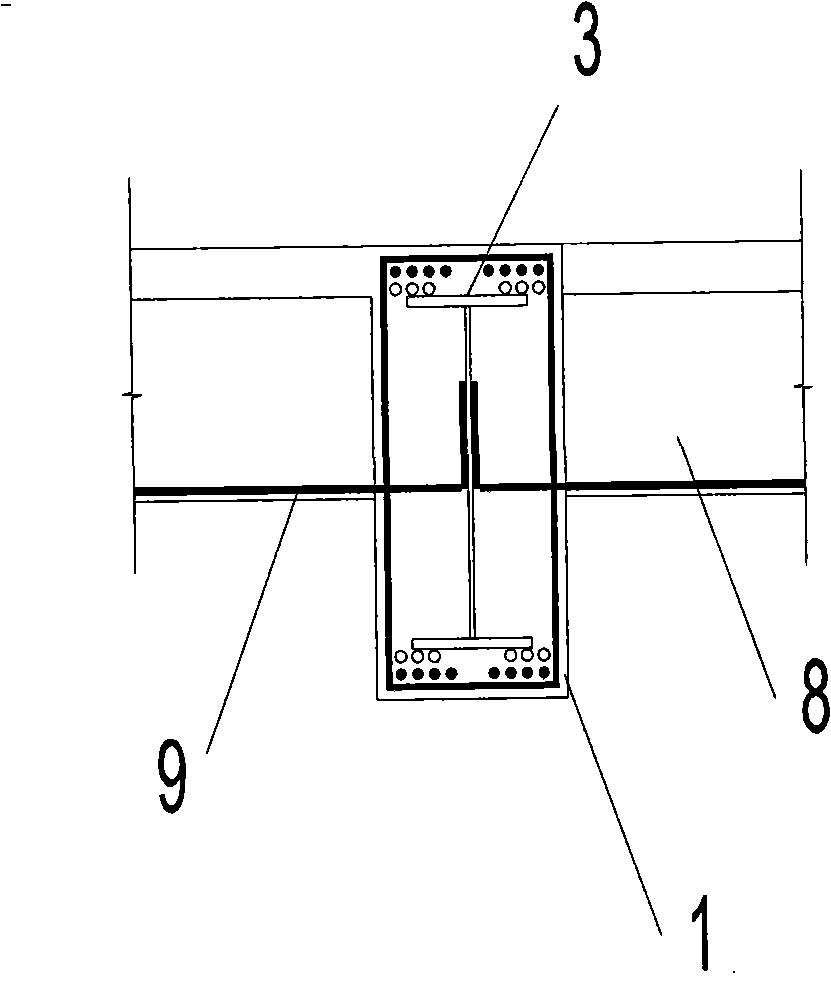

[0030] exist figure 2 In the shown embodiment, at the intersection of the ordinary non-frame beam 8 and the shaped steel beam 3 in the shaped steel concrete beam 1, the bottom reinforcement of the ordinary non-frame beam 8 breaks at the web of the shaped steel beam 3 and is anchored in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com