Bullet-proof glass and preparation method thereof

A technology of bulletproof glass and glass layer, which is applied in the direction of chemical instruments and methods, glass/slag layered products, lamination, etc. It can solve the problems of inability to adjust indoor light, overall volume weight, low thermal insulation performance, etc., and achieve improvement Good thermal insulation effect, good bulletproof effect, and good installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Prepare the bullet-proof glass in this embodiment according to the following preparation method

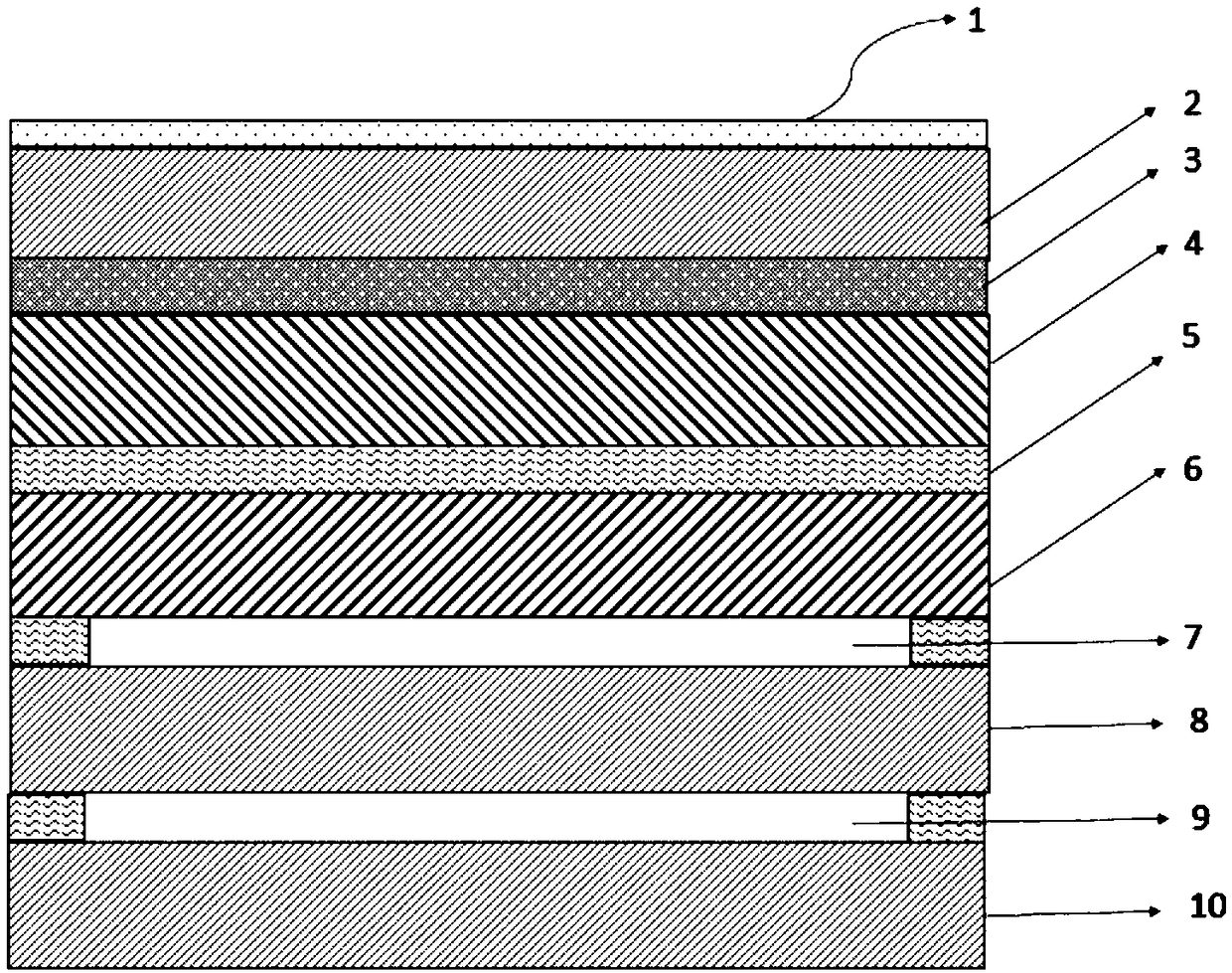

[0041] (1) After cleaning and drying the glass layer with a thickness of 3mm, the photovoltaic chip coating is deposited on the upper surface by co-evaporation technology, and the laser method is used to scribe different chip coating spacing dimensions and arrangement densities, so as to obtain the light transmittance 50% of the second glass layer 4;

[0042] (2) The chip coating of the second glass layer 4 with a light transmittance of 50% faces up, and after the first glass layer 2 is cleaned and dried, the first glass layer 2, the heat-insulating PVB adhesive film adhesive layer 3 and the second The second glass layer 4 is laminated sequentially from top to bottom, put into a preheated roller press for pre-pressing, keep the surface temperature of the glass after rolling at about 70°C, cool down for later use, and obtain a pre-pressed composite sample;

[0043](3) Put t...

Embodiment 2

[0051] Prepare the bullet-proof glass in this embodiment according to the following preparation method

[0052] (1) After cleaning and drying the glass layer with a thickness of 6 mm, the photovoltaic chip coating is deposited on the upper surface by co-evaporation technology, and the laser method is used to scribe different chip coating spacing dimensions and arrangement densities, so as to obtain the light transmittance 20% of the second glass layer 4;

[0053] (2) The chip coating of the second glass layer 4 with a light transmittance of 20% faces up, and after the first glass layer 2 is cleaned and dried, the first glass layer 2, the heat-insulating PVB adhesive film adhesive layer 3 and the second The second glass layer 4 is laminated sequentially from top to bottom, put into a preheated roller press for pre-pressing, keep the surface temperature of the glass after rolling at about 70°C, cool down for later use, and obtain a pre-pressed composite sample;

[0054] (3) Put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com