Integrated plastic faucet body forming method

An integrated, plastic technology, applied to household components, household appliances, and other household appliances, can solve problems such as high cost of faucet materials, qualitative changes in glue, and lack of resources, so as to improve production efficiency and quality, prolong service life, The effect is simple to make

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

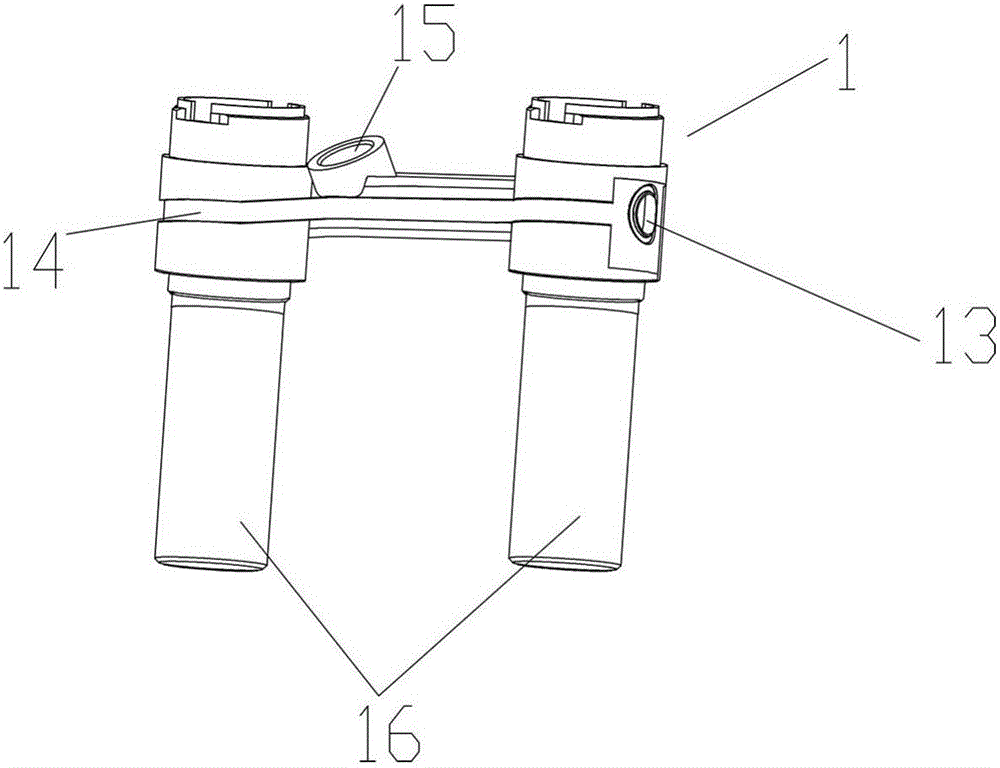

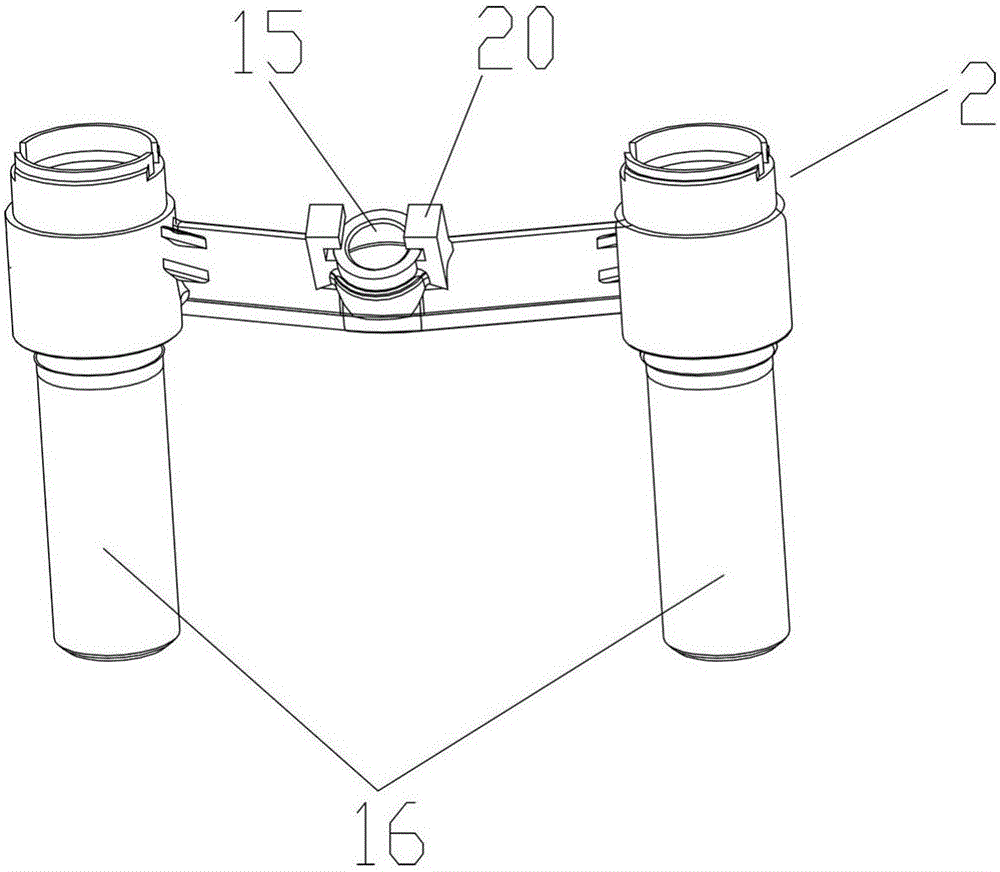

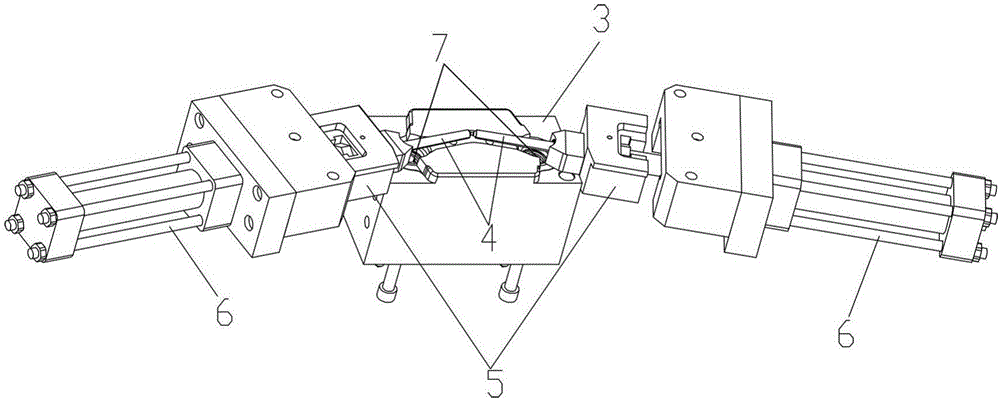

[0050] like Figure 1-8 As shown, a molding die for a one-piece plastic faucet body of the present invention is provided, including a mold base, and a first static mold cavity 24, a second static mold cavity 19 and a first movable mold cavity installed in the mold base. Core 3; after the first static mold cavity 24 is molded with the first movable mold core 3, perform the first injection molding to form the semi-finished product 1 of the integrated plastic faucet body; when the first static mold cavity 24 and the first movable mold After the mold core 3 is molded, the second static mold cavity 19 is molded with the first movable mold core 3, and the second injection molding is performed to form the finished product 2 of the integrated plastic faucet body.

[0051] Wherein, when the semi-finished product 1 is produced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com