Lift bean sprouting machine and control method thereof

A bean sprout machine, a lift-type technology, applied in electrical program control, botanical equipment and methods, program control in sequence/logic controllers, etc., can solve the problems of troublesome bean sprout machine volume, poor water and electricity isolation effect, and high production cost , to achieve the effect of light product quality, convenient use and cleaning, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

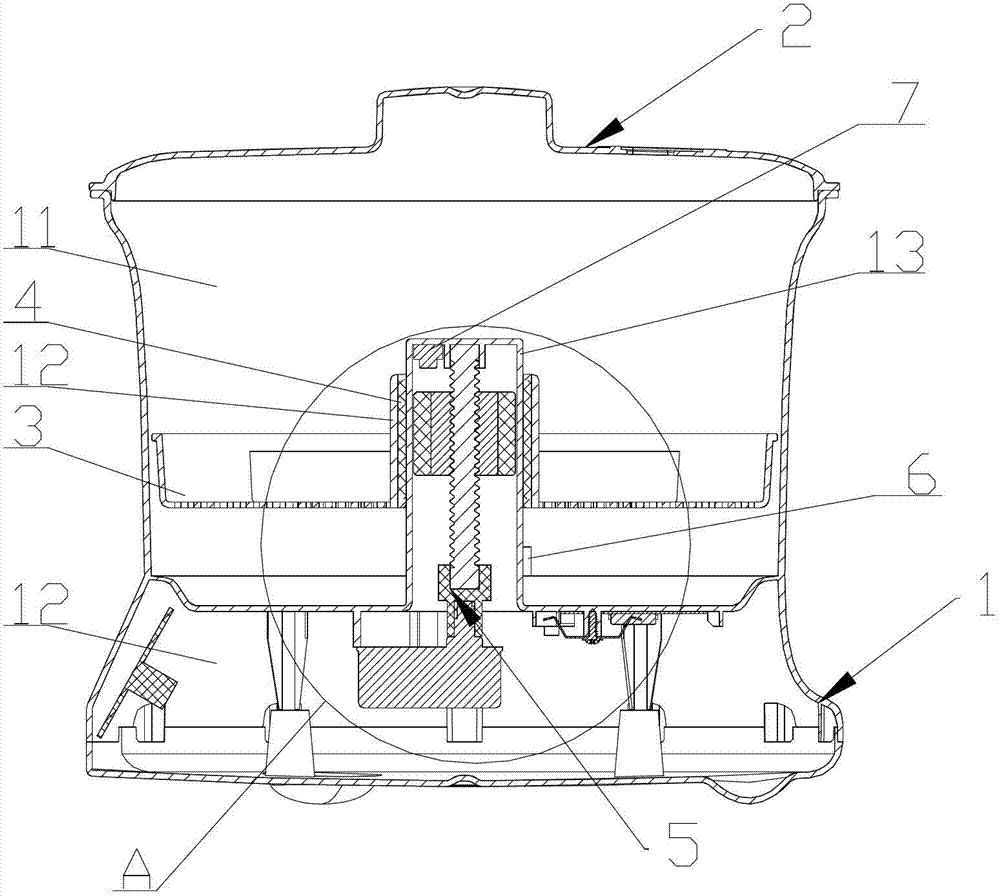

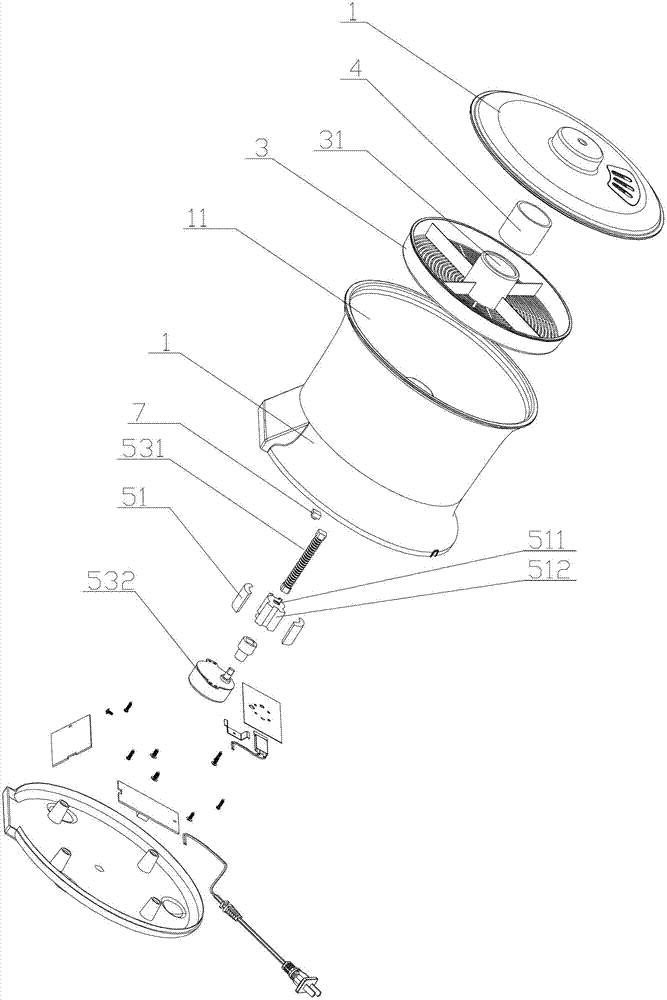

[0043] Embodiment one: if figure 1 As shown, the structure of this embodiment includes a housing 1, an upper cover 2 and a seedling raising tray 3, and the housing 1 is respectively provided with a seedling raising chamber 11 for cultivating bean sprouts and an electromechanical chamber 12 for arranging electromechanical components. The described seedling raising tray 3 is provided with a first part 4 for controlling the lifting of the seedling raising tray 3, and the housing 1 is provided with a second part 5 that cooperates with the first part 4 to control the raising and lowering of the seedling raising tray 3. The second part 5 It is a magnetic component that can control the movement of the first 4 parts up and down by magnetic force. Since the magnetic force can penetrate most materials, the first part 4 and the second part 5 can be respectively arranged in two mutually isolated spaces, that is to say the seedling chamber 11 where the first part 4 is placed and the second...

Embodiment 2

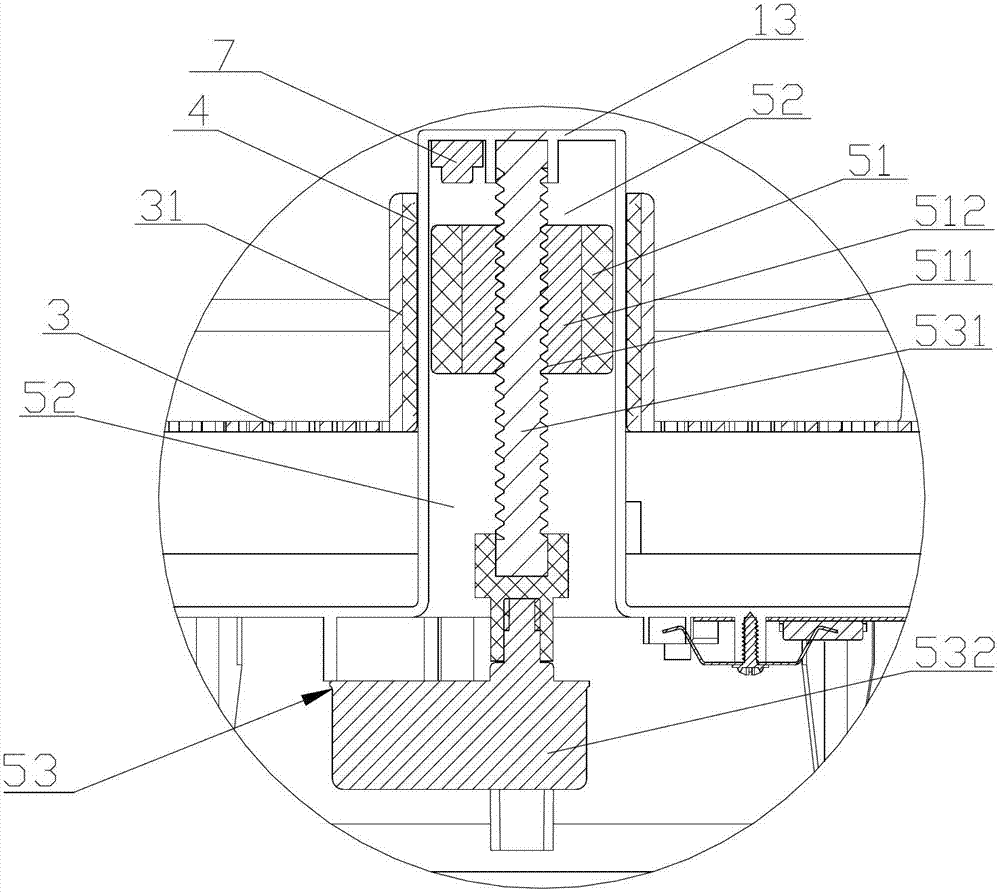

[0055] Embodiment two: as Figure 5 As shown, the structure of this embodiment is basically the same as that of Embodiment 1. Such as Figure 6 As shown, the difference is that a column 13 is arranged in the seedling room 11, and the directional track 52 is arranged in the column 13; the seedling tray 3 is provided with a through hole 31 matched with the column 13, and the The first component 4 is embedded in the hole wall of the through hole 31 , and the seedling raising tray 3 is connected with the column 13 through the through hole 31 . In addition to the simple structure of the seedling room 11 and the advantages of being convenient for users to use and clean, this structure has a smaller contact surface between the first part 4 and the water, which can greatly reduce the erosion of the first part 4 and has a relatively small impact on the water body. .

Embodiment 3

[0056] Embodiment three: as Figure 7 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, and the difference is that a flange 521 is provided on the orientation track 52 along the direction of the generatrix; The flange 521 is matingly connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com