Roll-seam adjustable flexible roll bending forming device

A roll gap, adjustable technology, applied in roll forming. ,In the field of flexible roll forming devices with adjustable roll gap, it can solve the problems of poor flexibility, high use cost, and heavy quality, and achieve the effects of sufficient material utilization, light product quality, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

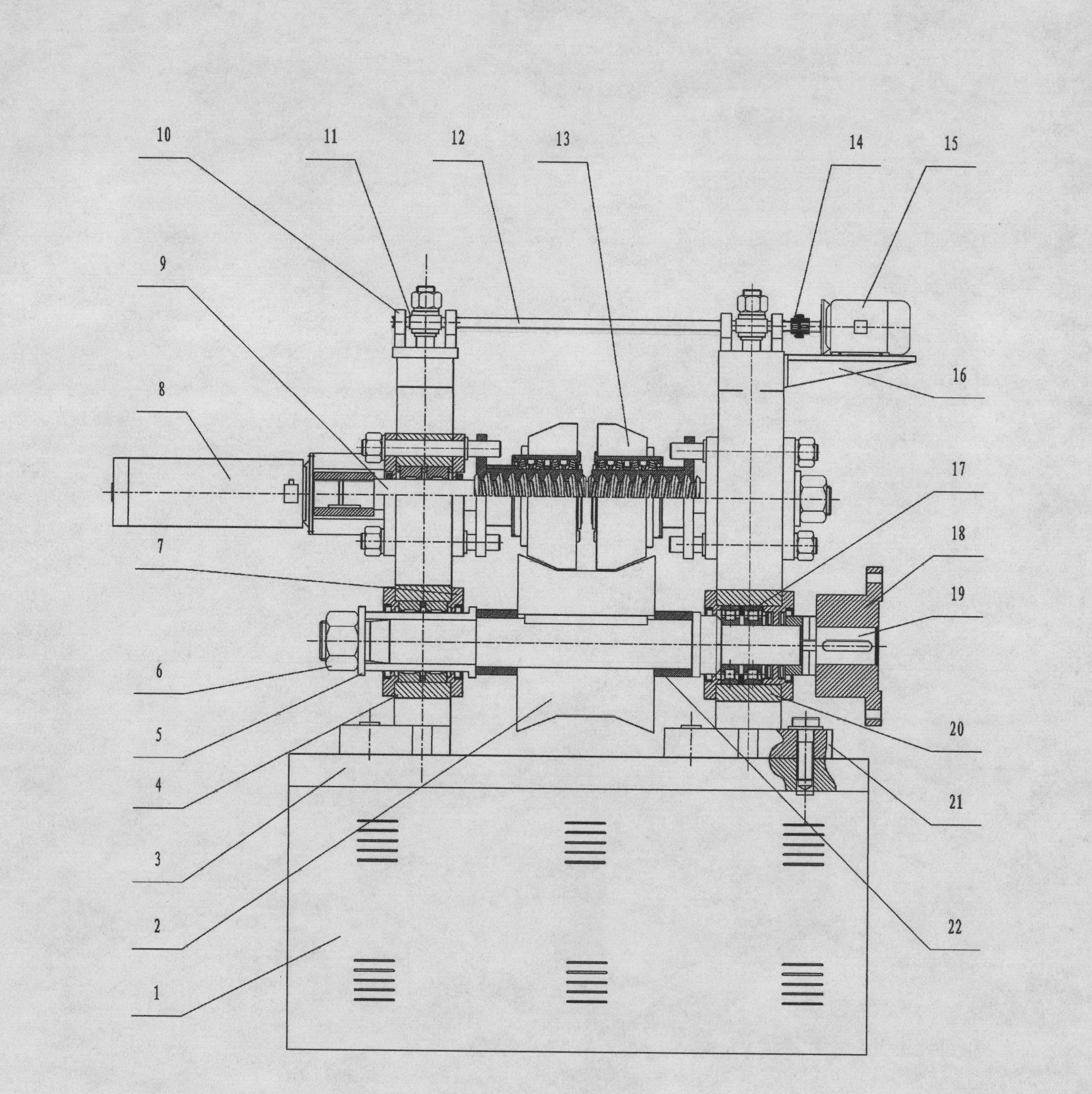

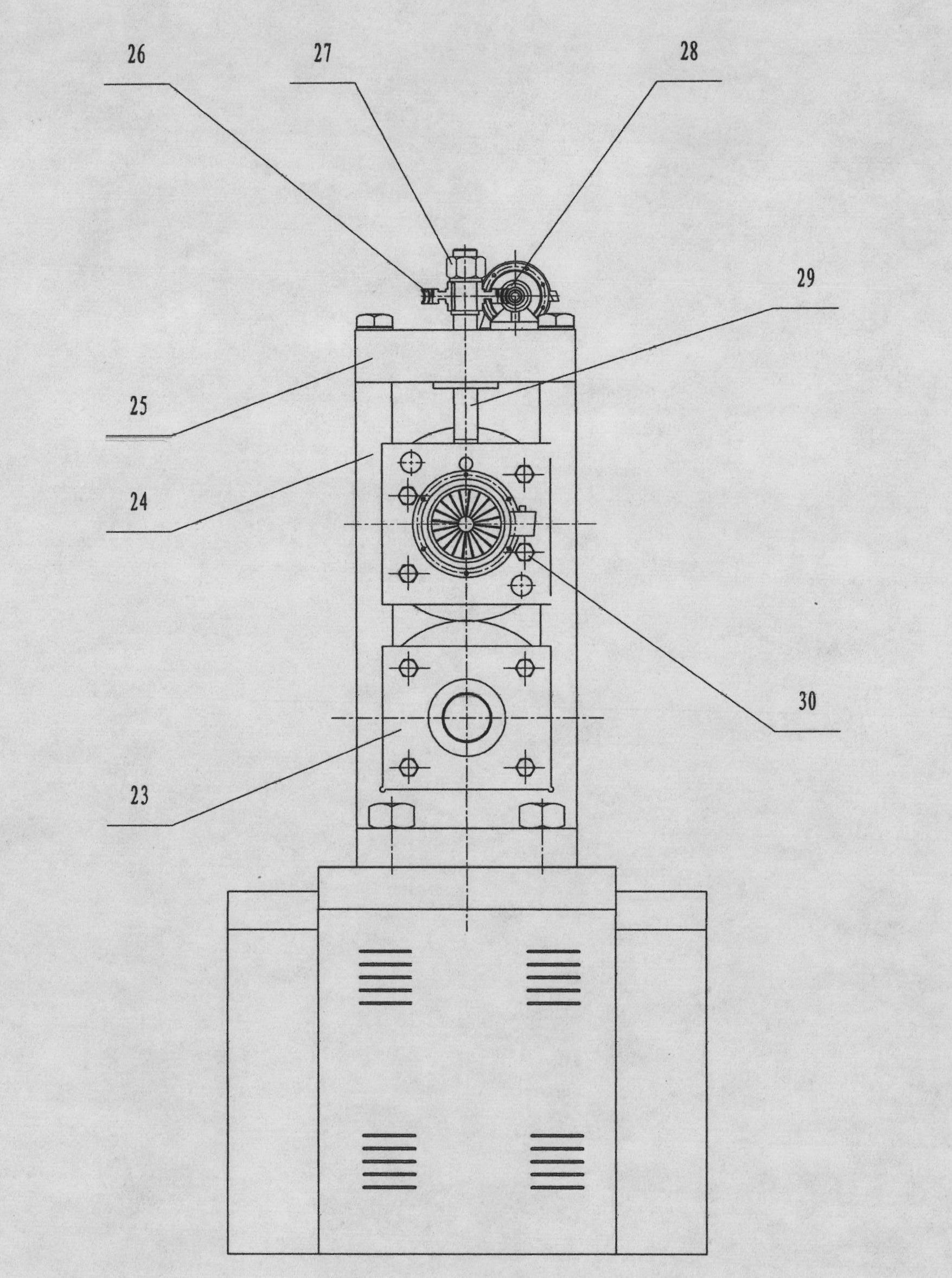

[0016] Such as figure 1 , figure 2 , image 3 The shown roll gap adjustable flexible roll forming device has a main structure including a toolbox 1, a workbench 3, a frame 21 and a frame 24 are arranged on the workbench 3, and the frame is equipped with a driving shaft system and a driven shaft Department, longitudinal adjustment device.

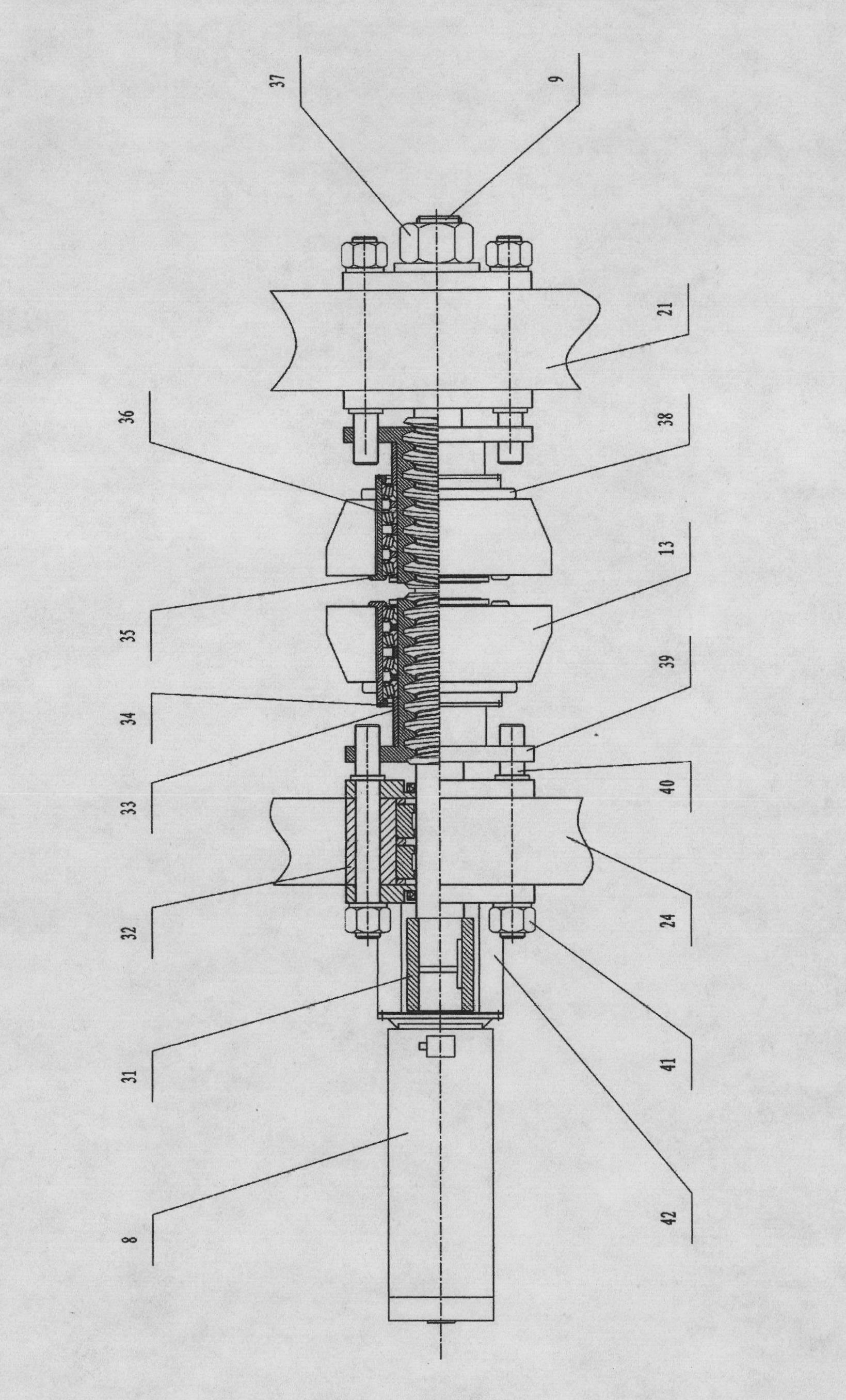

[0017] The structure of the above-mentioned driving shaft system is: the driving shaft 19 is fixed on the frame 21 and the frame 24 by the fixed block 4, the fixed block 20, the bearing 17, the end cover 23, the end cover 7, the shaft end fixing nut 6, etc. Between, driving roller 2 is assembled on the driving shaft 19 by axle sleeve 22, key etc.

[0018] The structure of the driven shaft system as described above is as follows: the driven roller 13 is fixed on the roller installation sleeve 35 by the key and the fixing nut 38, and the roller installation sleeve 35 is fixed by the shaft sleeve 33, the bearing 36, the end cover 34, etc. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com