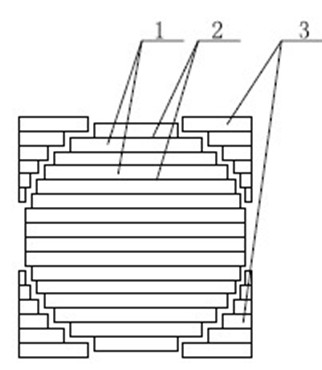

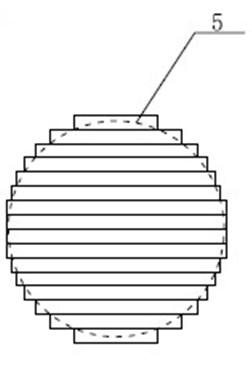

Structural glued-laminated timber round wooden column and manufacturing method thereof

A technology for glued wood and structures, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of decay and knots of log columns, easy cracking and deformation of log columns, and difficulty in obtaining round wood columns, etc., to achieve moisture content coordination Consistent, Inexpensive, Defect-Few Results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

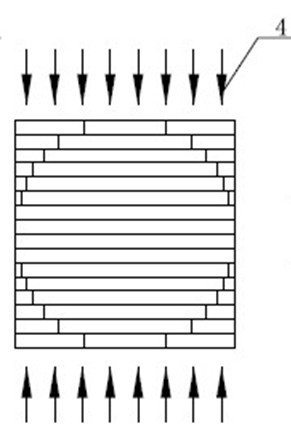

[0048] (1) Pretreatment of wood raw materials: according to the design requirements, through mechanical sawing and other processing methods, the inherent decay, knots, twill, cracks and insect holes of fast-growing wood raw materials are eliminated and controlled, and the thickness of 15~35mm, The solid wood is sawn with a width of 80mm and a length of 500~2000mm, and the wood is chemically modified to prevent corrosion and insects. Then, adjust the moisture content of the wood at 8% by artificial drying, and use it as the wood material for the laminated wood column for the structure;

[0049] (2) Production of laminates for glued wood: Carry out tooth milling on the end of the wood, the tooth length is 8~15mm, the inclination ratio of the finger tenon slope is 1 / 5, the fitting degree is 0.1mm, and the temperature is above 18°C and the relative humidity Under the environmental conditions of 50~70%, apply glue to the teeth, and the amount of glue applied is 350g / m 2 , apply ...

Embodiment 2

[0055] (1) Pretreatment of wood raw materials: according to the design requirements, through mechanical sawing and other processing methods, the inherent decay, knots, twill, cracks and insect holes of the structural wood raw materials are eliminated and controlled, and the thickness is 25~45mm. , Solid wood sawn timber with a width of 80~200mm and a length of 1000~4000mm. Then adjust the moisture content of the wood at 12% by artificial drying, and use it as the wood material for the laminated wood column for the structure;

[0056] (2) Manufacture of laminates for glued wood: Carry out tooth milling on the end of the wood, the tooth length is 25mm, the inclination ratio of the finger tenon slope is 1 / 7.5, the fitting degree is 0.25mm, and the temperature is above 18°C and the relative humidity is 80%. Under the environmental conditions, apply glue to the teeth, the amount of glue is 150g / m 2 , apply pressure along the direction of the grain of the wood to connect the leng...

Embodiment 3

[0062] (1) Pretreatment of wood raw materials: according to the design requirements, through mechanical sawing and other processing methods, the inherent decay, knots, twill, cracks and insect holes of the structural wood raw materials are eliminated and controlled, and the thickness is 25~45mm. , solid wood sawn timber with a width of 80-200mm and a length of 1000-4000mm, or selectively fire-resistant impregnated modified wood raw materials, and then artificially dried to adjust the moisture content of the wood to 10%, as a structure Timber material for laminated lumber round posts;

[0063] (2) Manufacture of laminates for glued wood: Carry out tooth milling on the end of the wood, the tooth length is 20mm, the inclination ratio of the finger-tenon slope is 1 / 6, the fitting degree is 0.2mm, and the temperature is above 18°C and the relative humidity is 60%. Under the environmental conditions, apply glue to the teeth, the amount of glue is 250g / m 2 , apply pressure along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com