Reproduced stone and preparing method thereof

A technology for reconstituting stone and manufacturing method, applied in chemical instruments and methods, special decorative structures, decorative arts, etc., can solve the problems of increased curing time, high construction conditions, prolonged product production cycle, etc., to improve toughness and firmness, The effect of low requirements on construction conditions and shortened curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

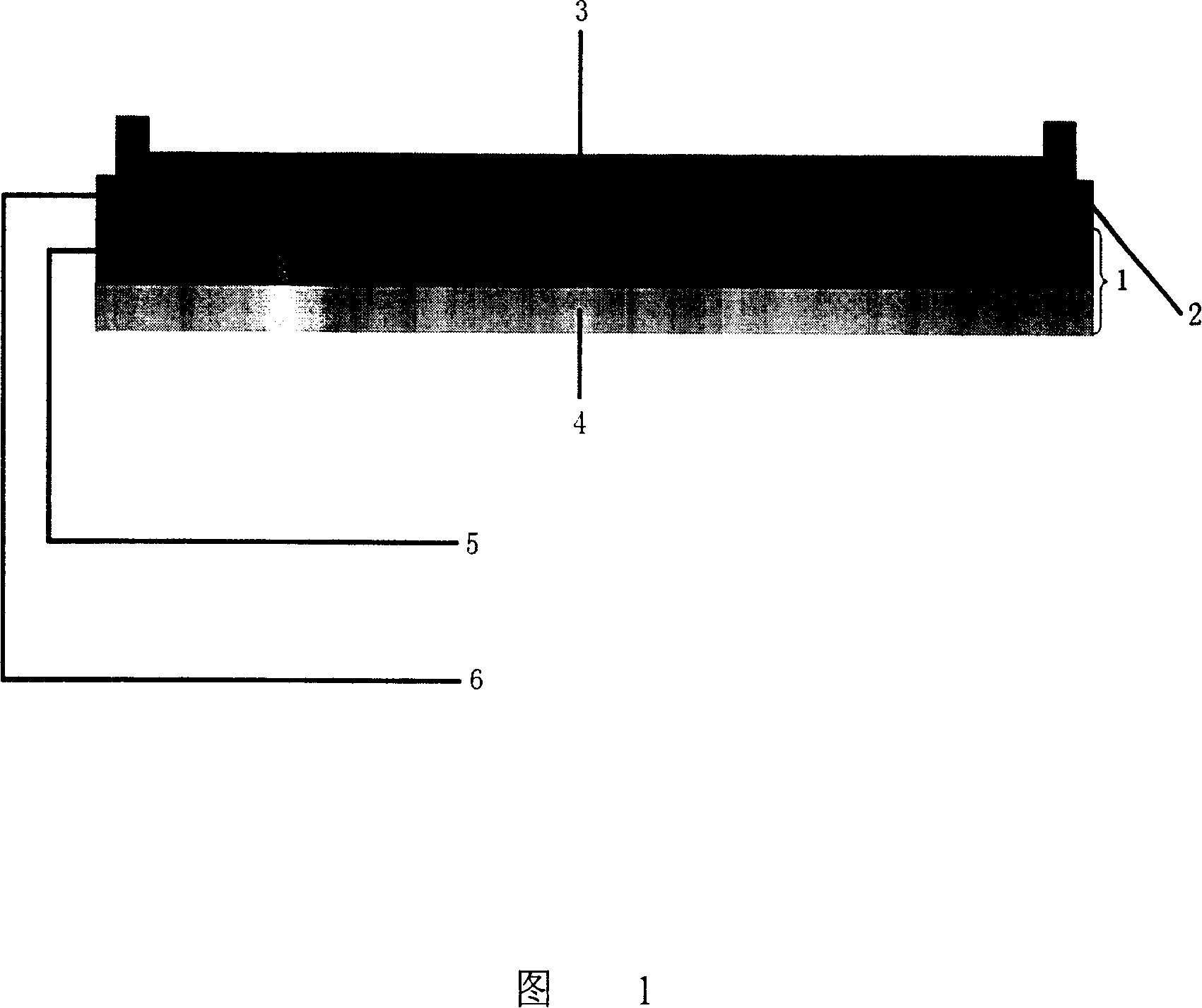

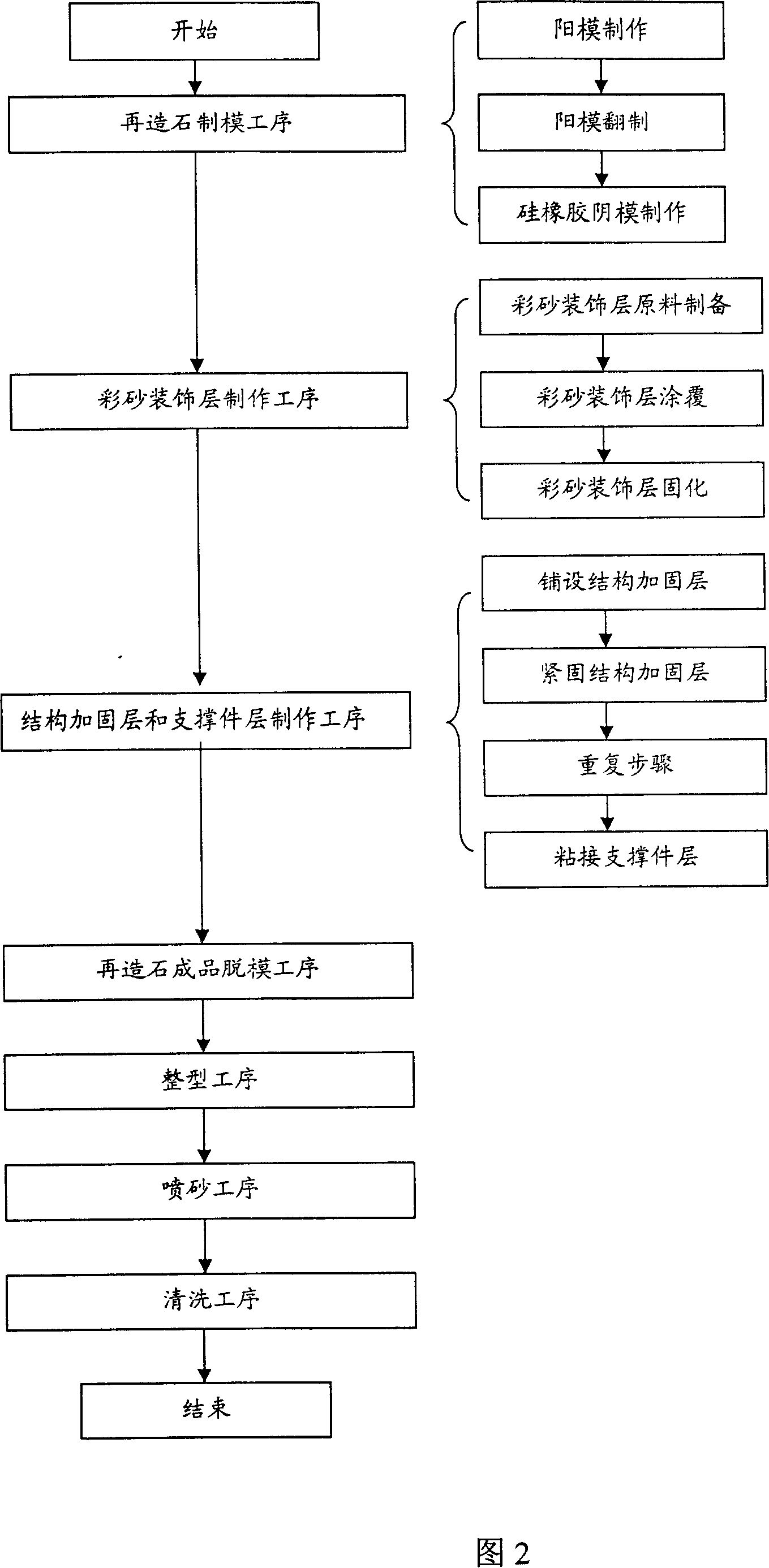

[0058] Figure 1 is a schematic cross-sectional structure diagram of the product.

[0059] The reconstituted stone is a multi-layer structure, including in turn: a colored sand decorative layer 1, a structural reinforcement layer 2 and a support layer 3; a structural reinforcement layer 2 is laid on the inner side of the colored sand decorative layer 1, and the structural reinforcement layer 2 is used for Reinforce the reconstituted stone flakes; the support member 3 layer is arranged inside the structural reinforcement layer 2, and the support member 3 is used to integrally erect the reconstituted stone flakes.

[0060] In order to make the reconstituted stone structure firm, a colored sand decorative thickening layer 5 is arranged inside the colored sand decorative surface layer 4 of the colored sand decorative layer 1, that is, one to three layers of colored sand are sprayed or coated behind the decorative surface layer 4 It is used to thicken the surface layer 4; the struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com