Precision-investment casting method

A technology of investment precision casting and investment molding, which is applied in the direction of casting molding equipment, molds, mold components, etc., can solve the problems of uneven structural strength, poor pressure bearing capacity, increased energy consumption, etc., and achieve the goal of saving manpower and material resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

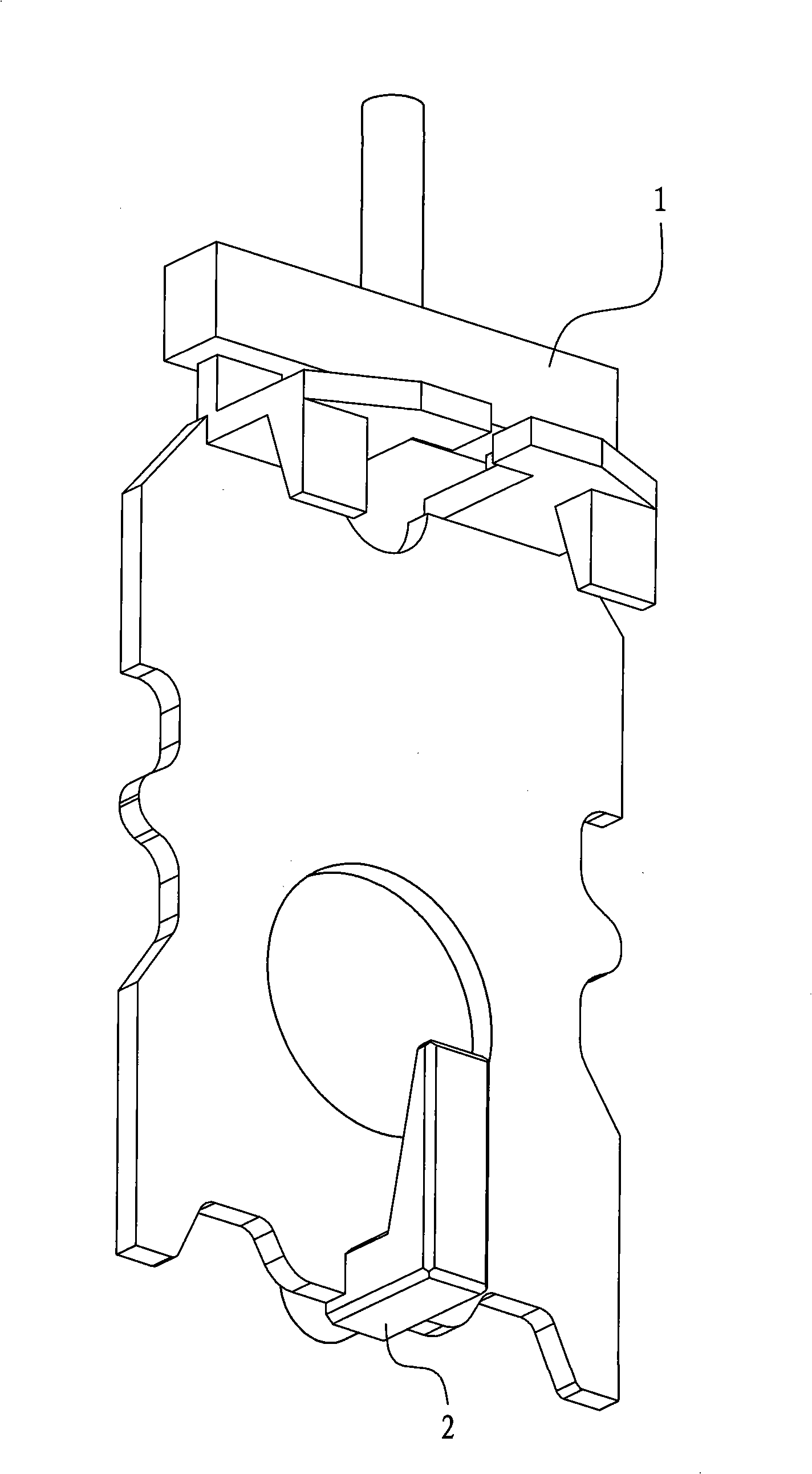

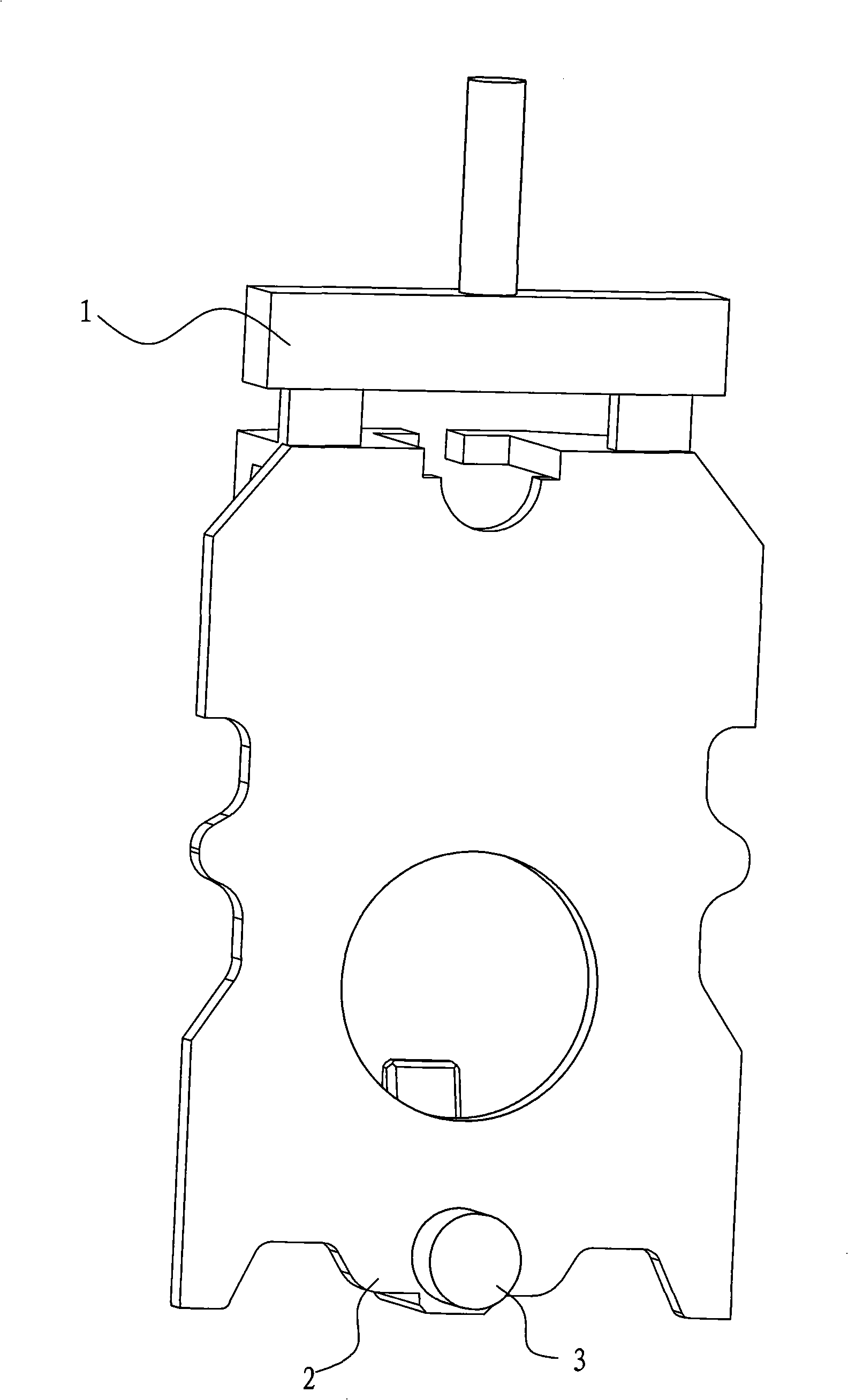

[0015] refer to figure 1 and figure 2 , the embodiment discloses an investment casting method, comprising the following steps:

[0016] 1. Make a wax mold that is consistent with the casting and includes the riser 1, and set a core head on the hot joint 2 of the casting corresponding to the wax mold that is far away from the riser 1, and the core head and the wax mold are integrally formed;

[0017] 2. Make a silica sol investment pattern according to the wax pattern, and wipe off the floating sand at the end of the mud core head after the production is completed and ensure that it is located outside the silica sol investment pattern; on this premise, prepare the silica sol investment pattern The process is a known technique, which is fully disclosed in the documents mentioned in the background;

[0018] 3. Place the prepared silica sol investment mold at a temperature of 110°C to 120°C for lost wax treatment to obtain a mold shell, which contains a reserved opening corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com