Method for forming frame, stringer and covering of composite material component through integrated co-curing

A composite material, curing molding technology, applied in the direction of household components, household appliances, other household appliances, etc., can solve problems such as degumming, affecting flight safety, interface effects, etc., and achieve the effect of meeting the strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

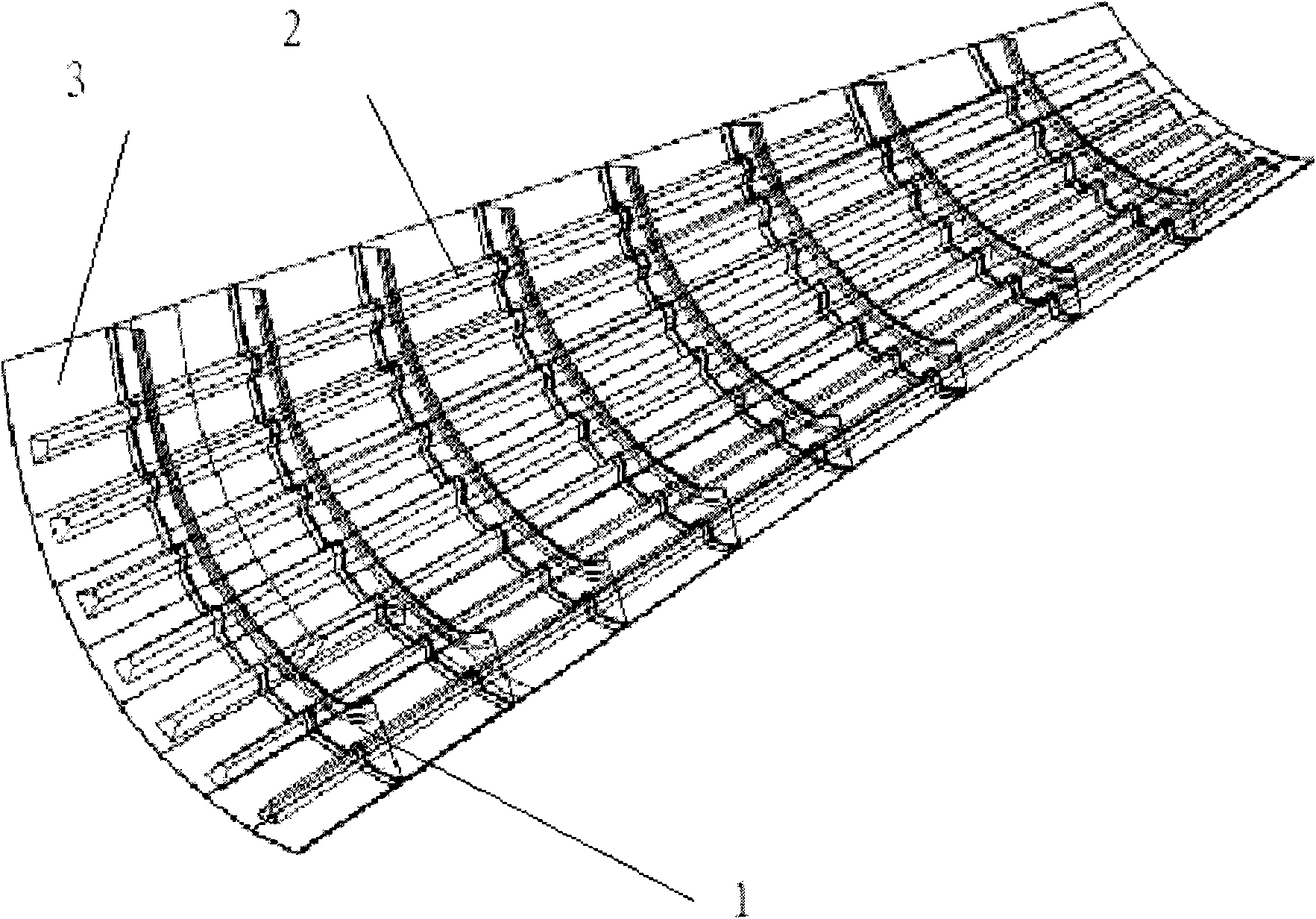

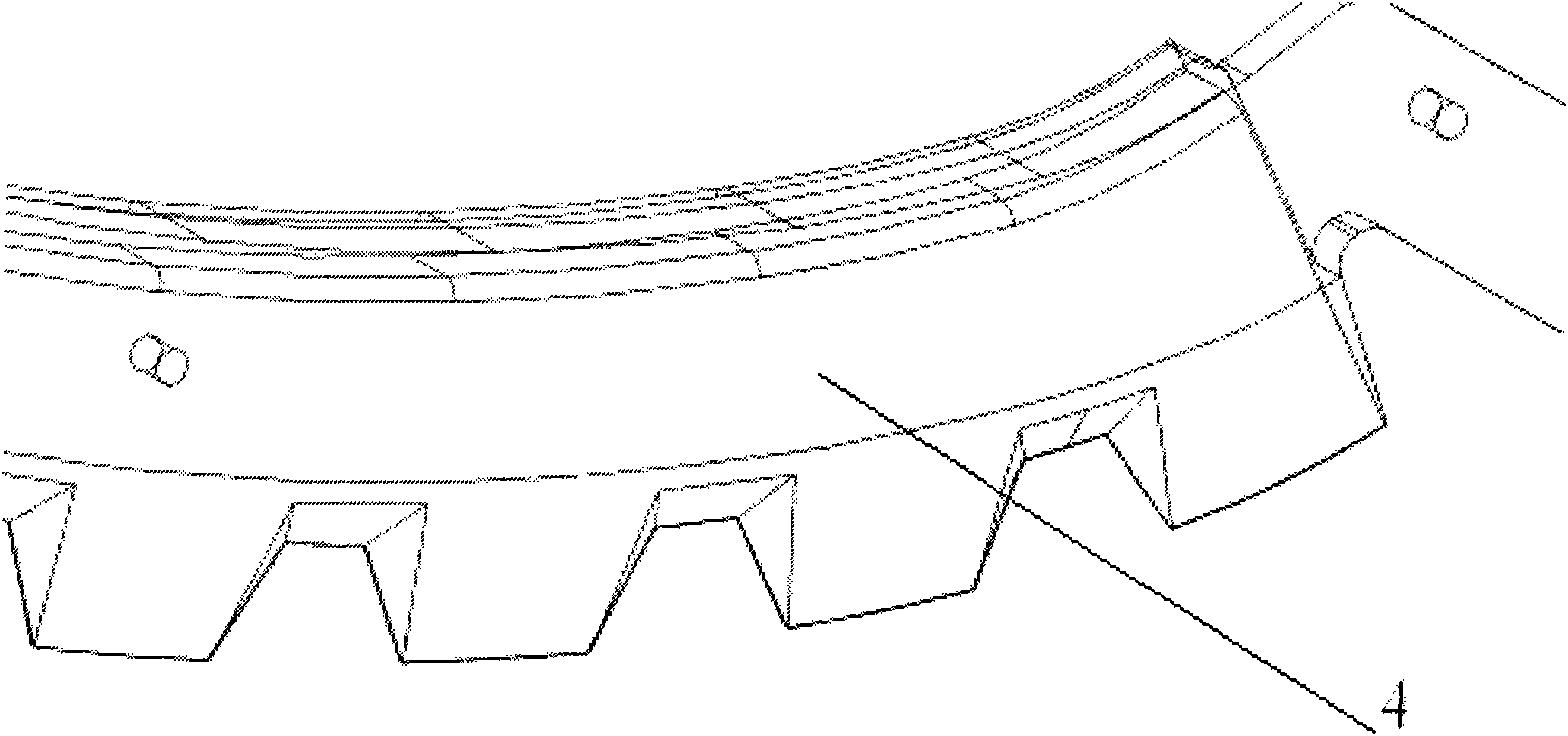

[0015] The present invention will be described in further detail below. The overall co-curing molding method of the composite material component frame, stringer and skin adopts one-time co-curing molding for complex composite components, which solves the problems at the joint surface between the frame, beam and skin in the traditional secondary adhesive molding. Adhesive interface effect.

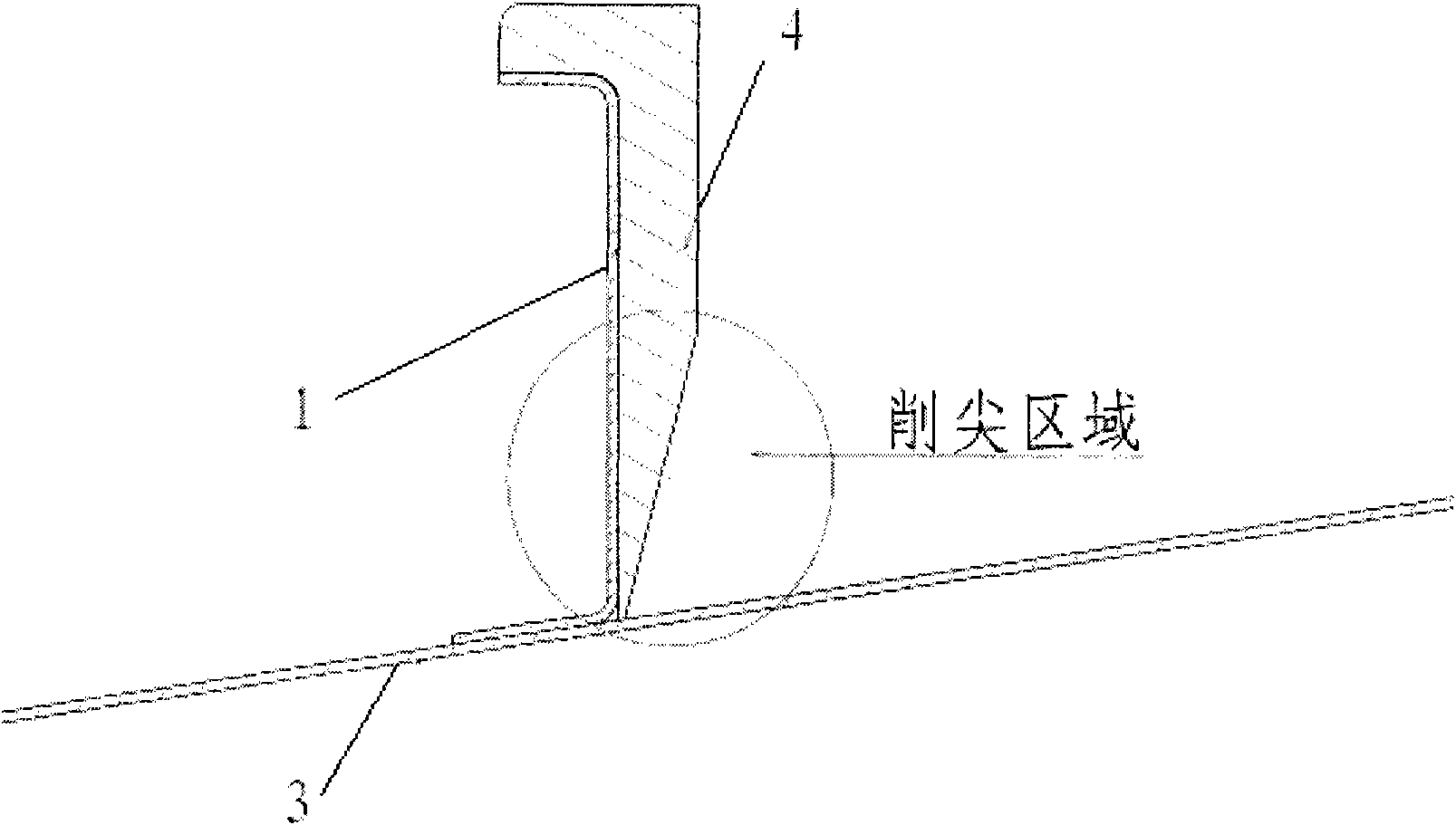

[0016] The working principle of the present invention is: use advanced temperature-resistant and pressure-resistant foam as the inner filling of the stringer, so that the stringer and the skin can be paved and pasted at one time; use the positioning and curing tooling of the frame that has been specially sharpened to solve the problem of the frame The pressure problem at the joint surface of the beams realizes the co-curing molding of the frame and the skin long truss components; the rubber lining mold technology is used to ensure the uniformity of the pressure of the internal complex struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com