Steel box type composite beam forming method

A forming method and technology of composite beams, which are applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as the deformation of the bottom box of the force-transmitting tendon, and achieve the effects of light transportation and installation, material saving, and rapid assembly and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

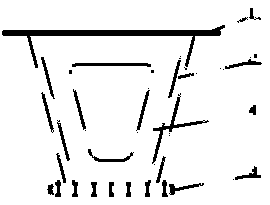

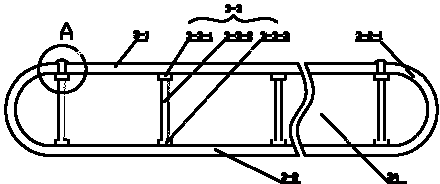

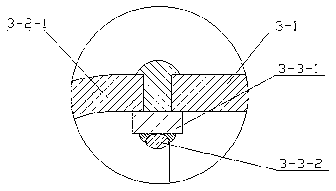

[0069] A forming method of a steel box type composite beam, the structure of the composite beam includes a top plate, a corrugated plate and a bottom box. The processing method of the steel box-type composite beam includes blank cutting and pretreatment in the early stage, processing procedures of the bottom box, processing procedures of the corrugated plate, processing procedures of the top plate, and a welding procedure. Specific steps include:

[0070] A. Uncoil and level the steel coil, and cut it into equal-length bottom box bottom plate blanks, bottom box top plate blanks, corrugated web plate blanks and top plate blanks for forming the bottom box according to the design size; use an uncoiler, leveling The steel coil is unrolled, roughly calibrated and finely calibrated into a steel plate with flatness that meets the requirements, and transported to the cutting station by the roller conveying equipment. According to the design requirements, the steel coil is cut longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com