Aluminum profile spraying production line

An aluminum profile and production line technology, applied in spray booths, spray devices, etc., can solve the problems of single fixture function, unable to improve cleaning and spraying efficiency, unable to adapt to various sizes, etc., to achieve the effect of wide application and easy popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

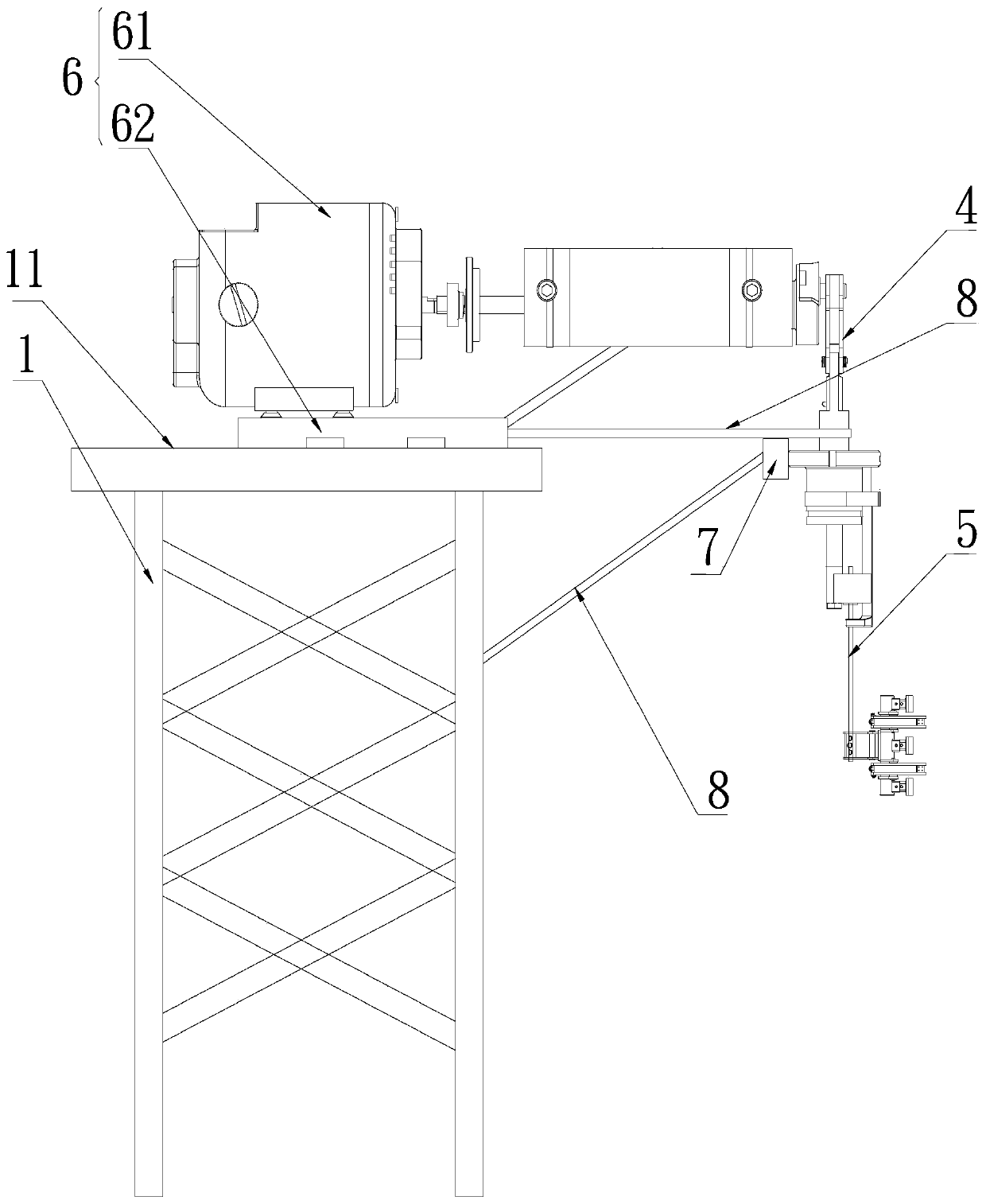

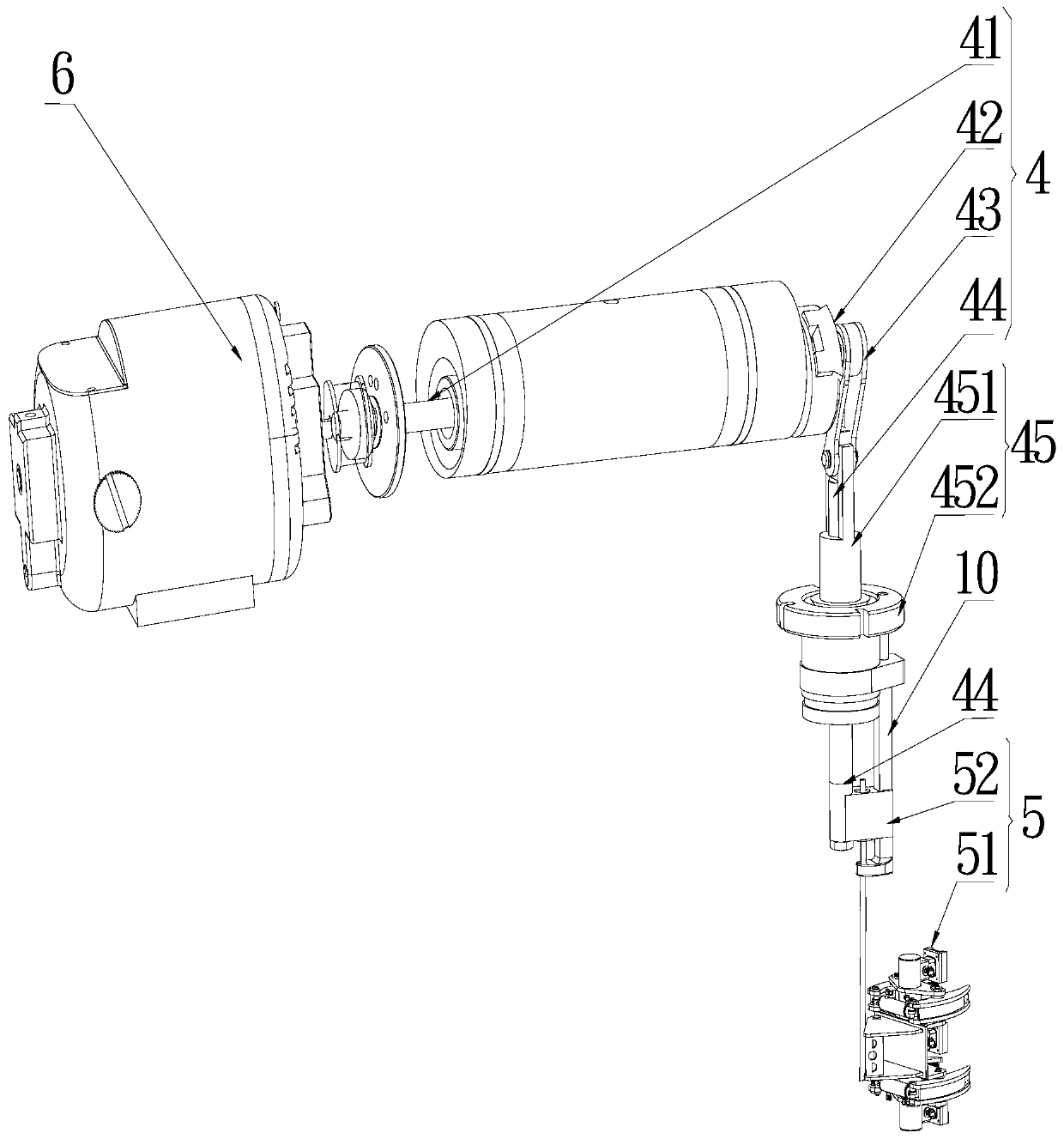

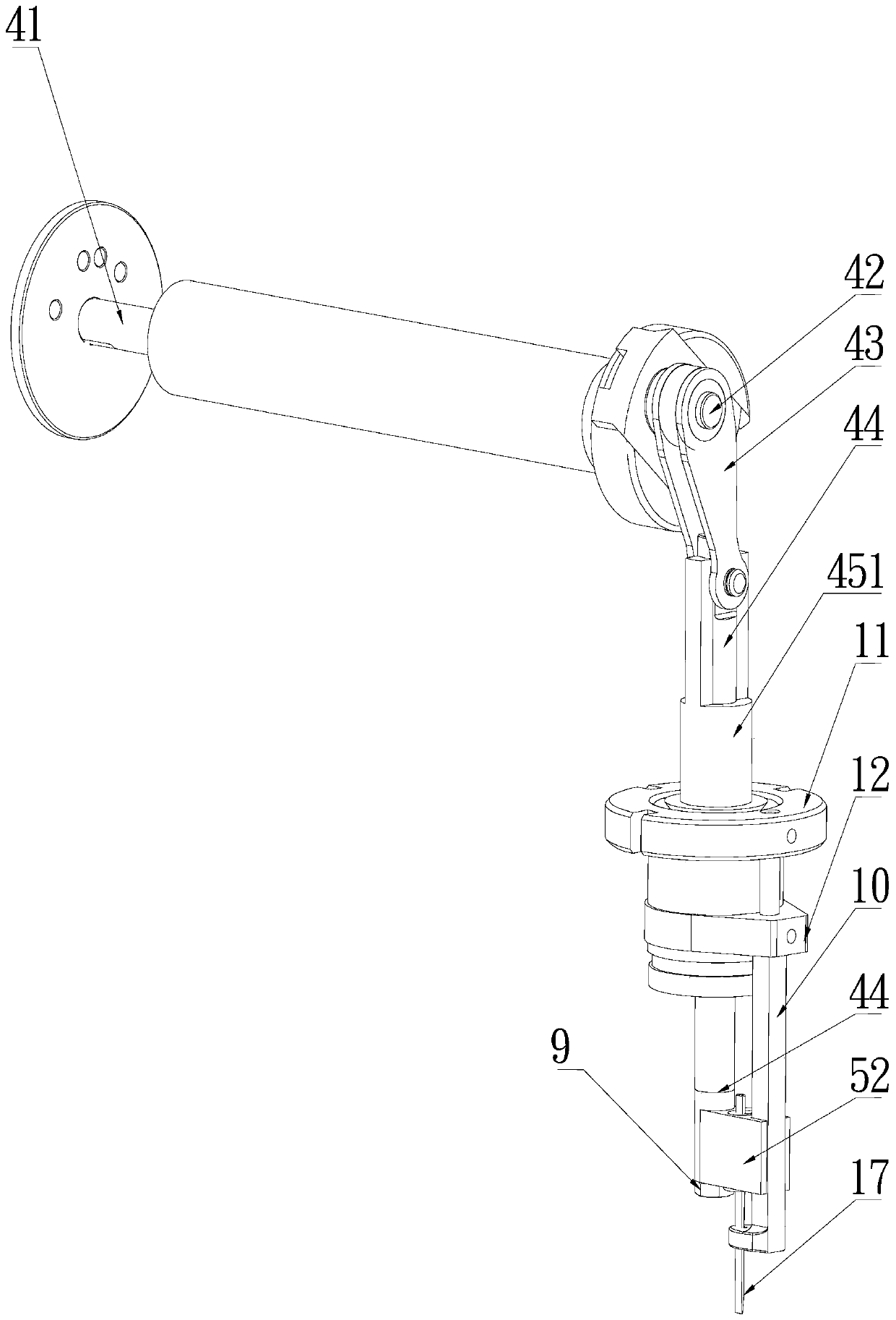

[0036] Such as Figure 1-8 A spraying production line for aluminum profiles is shown, which includes a conveying device, a spraying device 2 and several clamping devices 3; the conveying device includes a frame 1, a turntable 11 arranged above the frame 1 and a The rotating block 12 that the turntable 11 rotates; several clamping devices 3 are arranged on the turntable, and the clamping parts of the clamping devices 3 extend out of the turntable 11; the spraying device 2 is located The side of the clamping portion of the clamping device 3, and the spraying portion of the spraying device 2 faces the clamping portion of the clamping device 3; the clamping device 3 includes a transmission block 4, a clamping block 5 And the driving block 6 used to drive the lifting movement of the clamping block 5; the transmission block 4 includes a rotating shaft 41, an eccentric wheel 42, a connecting arm 43, a connecting shaft 44 and a rotating sleeve 45 arranged vertically; One end of the r...

Embodiment 2

[0046] Such as Figure 1-8 A spraying production line for aluminum profiles is shown, which includes a conveying device, a spraying device 2 and several clamping devices 3; the conveying device includes a frame 1, a turntable 11 arranged above the frame 1 and a The rotating block 12 that the turntable 11 rotates; several clamping devices 3 are arranged on the turntable, and the clamping parts of the clamping devices 3 extend out of the turntable 11; the spraying device 2 is located The side of the clamping portion of the clamping device 3, and the spraying portion of the spraying device 2 faces the clamping portion of the clamping device 3; the clamping device 3 includes a transmission block 4, a clamping block 5 And the driving block 6 used to drive the lifting movement of the clamping block 5; the transmission block 4 includes a rotating shaft 41, an eccentric wheel 42, a connecting arm 43, a connecting shaft 44 and a rotating sleeve 45 arranged vertically; One end of the r...

Embodiment 3

[0057] The implementation about the spraying device 3 in this embodiment 3 includes a power supply, an air source and a spray gun, and also includes a power control module, an air source pressure control module, a spray gun angle control module and a spray gun position control module; The spray gun is connected with the power control module, and the power control module is used to control the power switch of the spray gun; the air source is connected with the spray gun and the air source pressure control module respectively, and the air source pressure The control module is used to control the air source switch and pressure status of the spray gun; the spray gun angle control module is connected with the spray gun to control the angle parameter of the spray gun; the spray gun position control module is connected with the spray gun The spray gun is connected to control the initial position parameters of the spray gun; the power supply control module is respectively connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com