Automatic manipulator of caster support press line

A technology for manipulators and punching lines, which is applied to manipulators, program-controlled manipulators, metal processing equipment, etc., to achieve the effects of simple and compact structure, low cost and large adjustment range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the implementation of the present invention is not limited thereto.

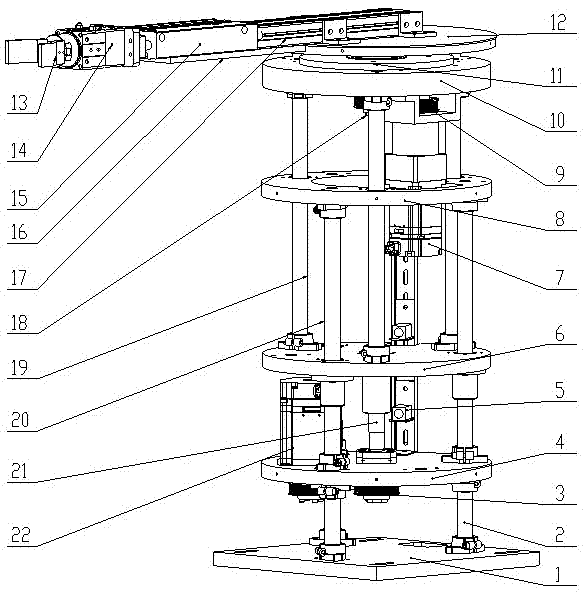

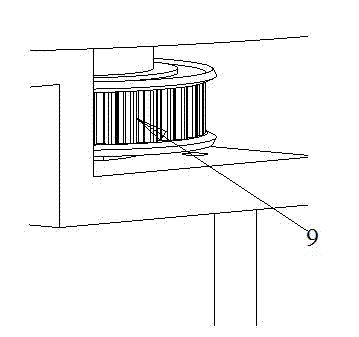

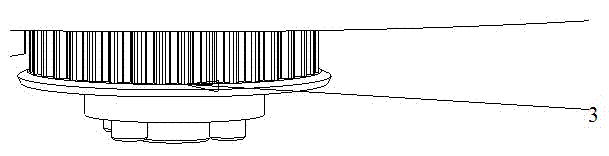

[0019] Such as Figure 1a ~ Figure 1c , figure 2 , caster bracket stamping line automation manipulator includes shell, structural support, electric manipulator, driving device and control device, described shell is divided into upper layer shell 23 and lower layer shell 24, fixed plate 1 fixes lower base 4 through 3 support guide pillars 2 , The lower base 4 is connected with the upper base 8 with 3 base guide shafts 20 . The lower lifting platform 6 is installed between the upper and lower bases, and is passed by the base guide shaft 20. The upper lifting platform 10 is connected with the lower lifting platform 6 by 3 lifting platform guide shafts 19, and the lifting platform guide shaft 19 passes through the upper base 8. Ball screw mandrel 21 is housed on the lower lifting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com