Robot roller hemming bed fixture with lifting mechanism

A technology of hemming fixtures and membranes, which is applied in the direction of manufacturing tools, metal processing equipment, feeding devices, etc., can solve the problems of lack of lifting mechanisms, etc., and achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

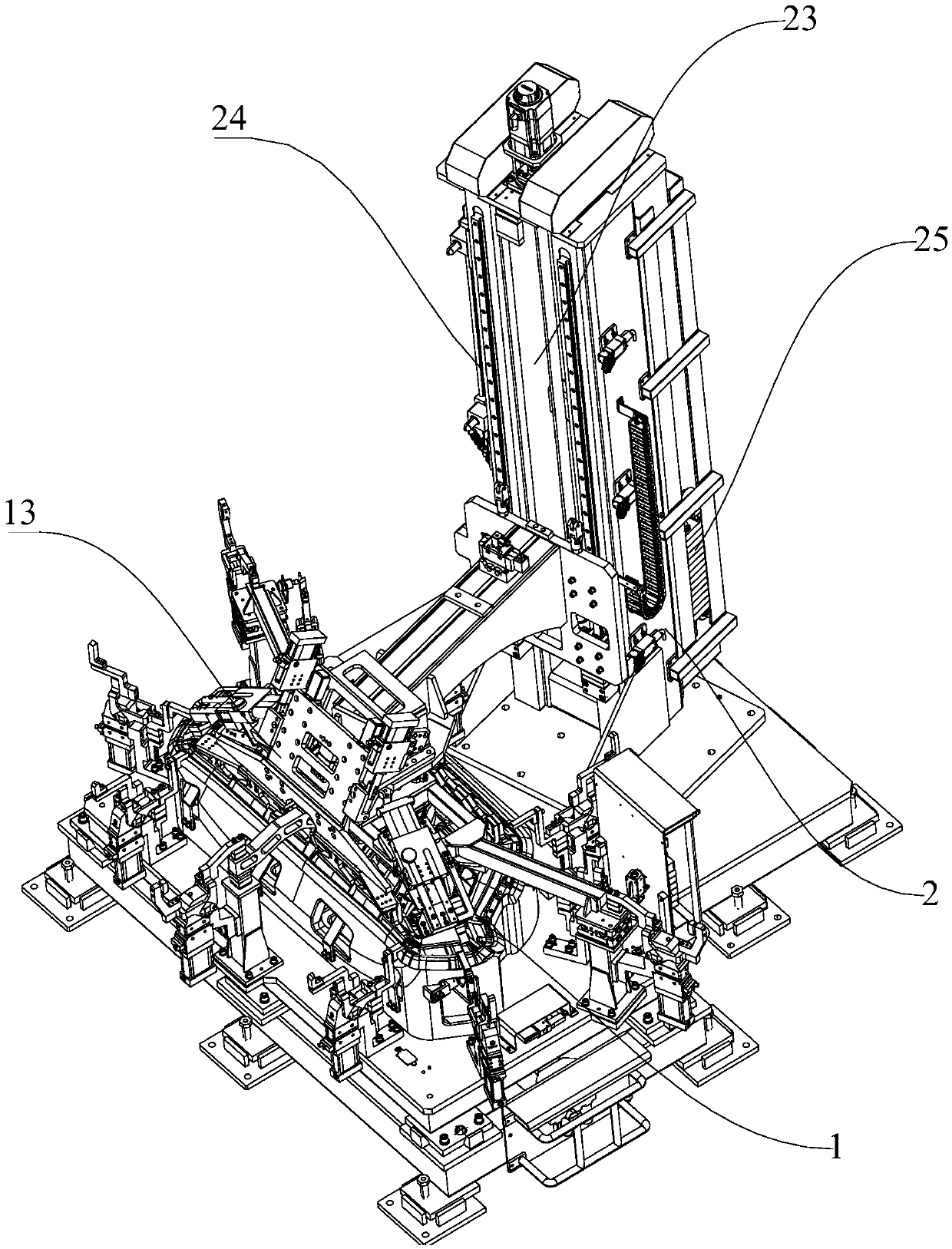

[0034] Such as figure 1 As shown, a hemming film clamp with a lifting mechanism in this embodiment has a simple structure and is easy to use, and includes a hemming clamp 1 and a lifting mechanism 2 .

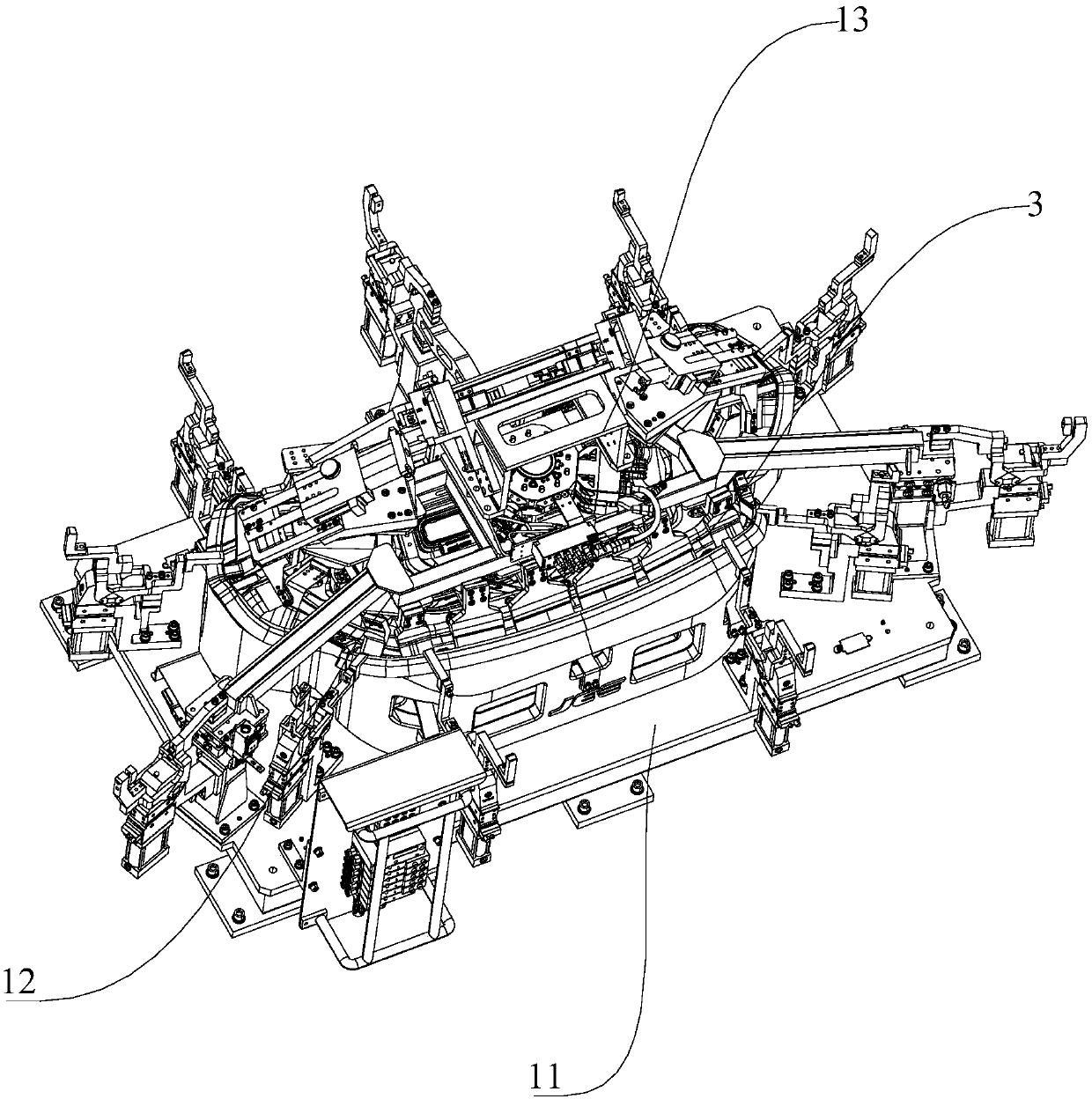

[0035] see figure 2 , The hemming clamp 1 includes a BASE frame 11 , a clamping film member 12 and a positioning gripper 13 located on the BASE frame 11 , and are used to jointly fix the body panel 3 . Wherein, the clamping membrane part 12 cooperates with the outer plate of the workpiece, and is used to compress the outer plate of the workpiece; the positioning gripper 13 is arranged above the clamping membrane part 12, cooperates with the inner plate of the workpiece, and is used for the inner plate of the workpiece to be placed on the outer plate of the workpiece. fixed on the board.

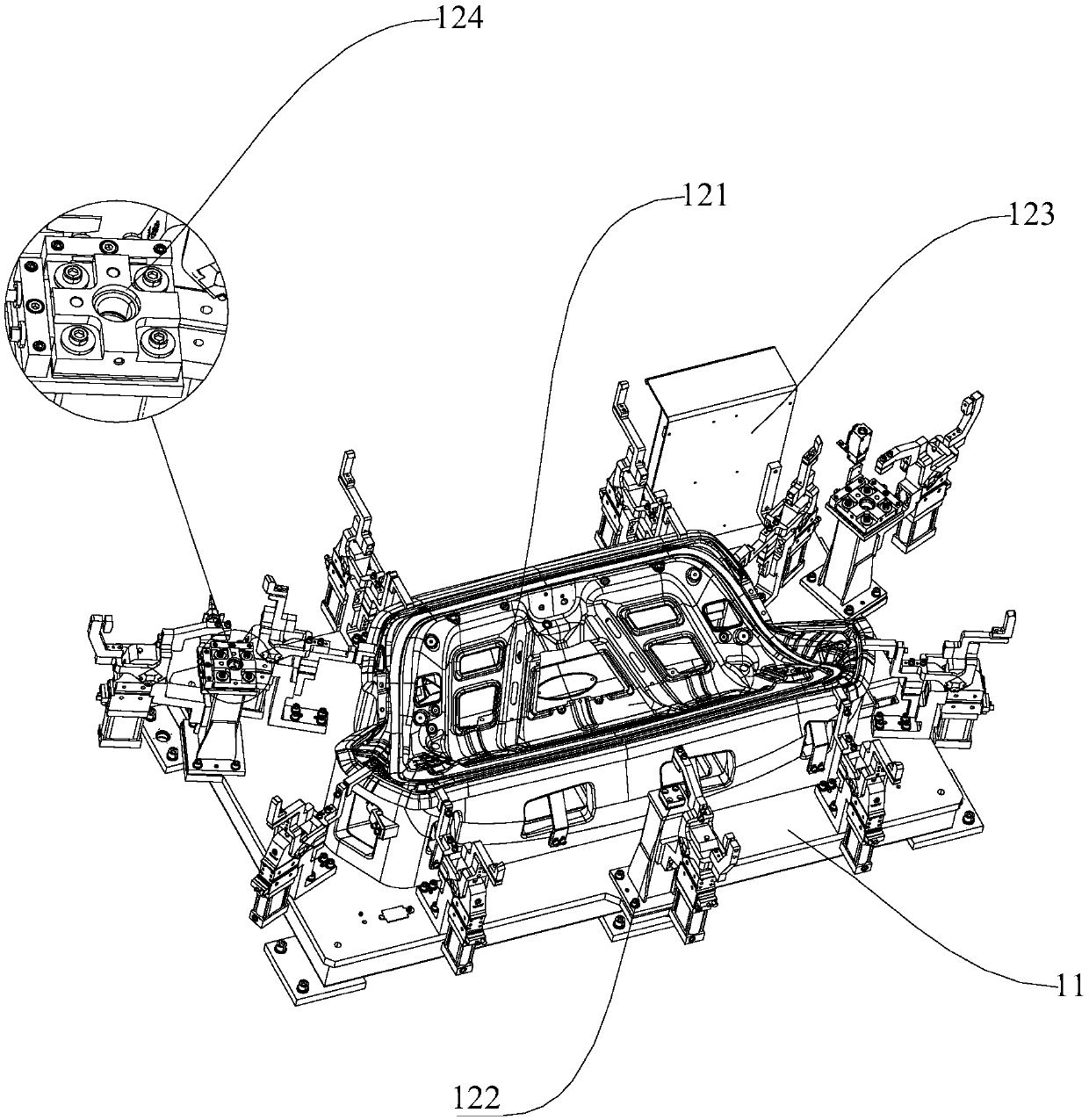

[0036] see image 3 The clamping membrane component 12 specifically includes a rolled membrane 121 , a first pressing unit 122 , a valve island 123 and a gripper positioning device 124 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com