Automatic clamping and feeding mechanical gripper

A mechanical gripper and automatic technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of increasing labor costs, reducing and wasting operator working time, and achieves lower labor costs, lower labor operations, and reasonable structural design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

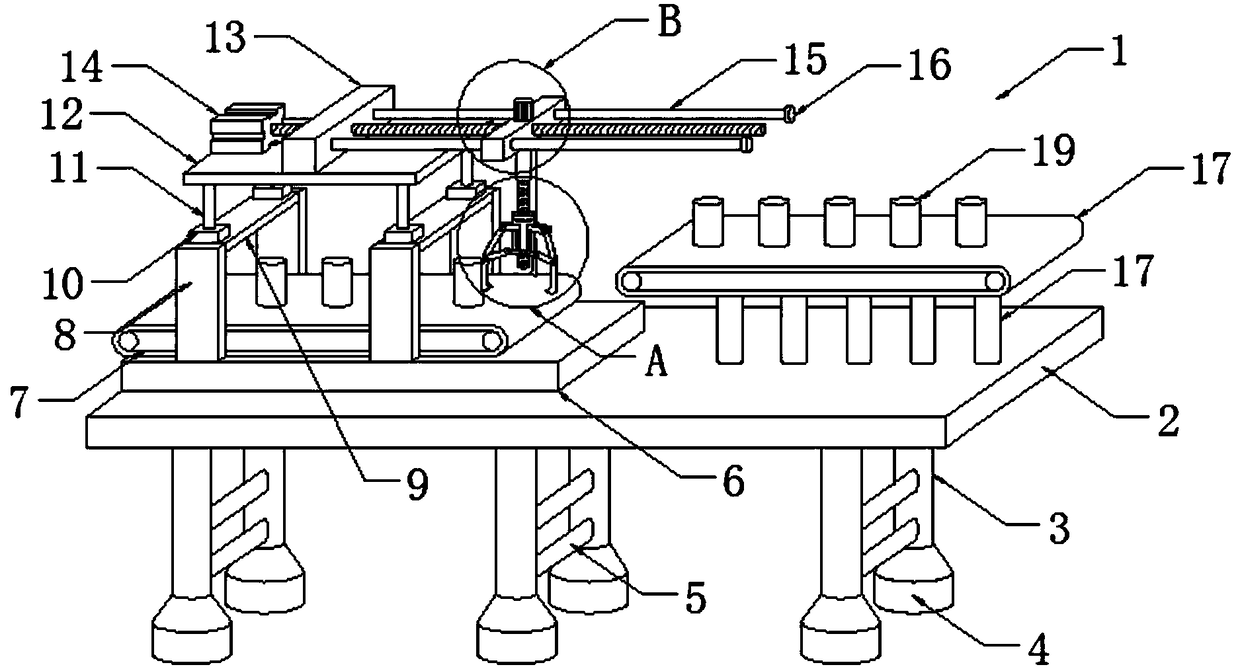

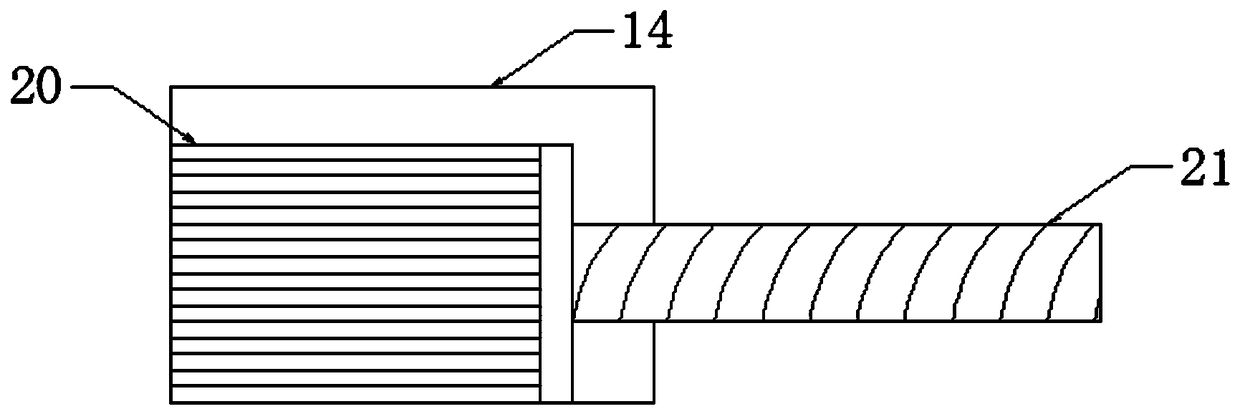

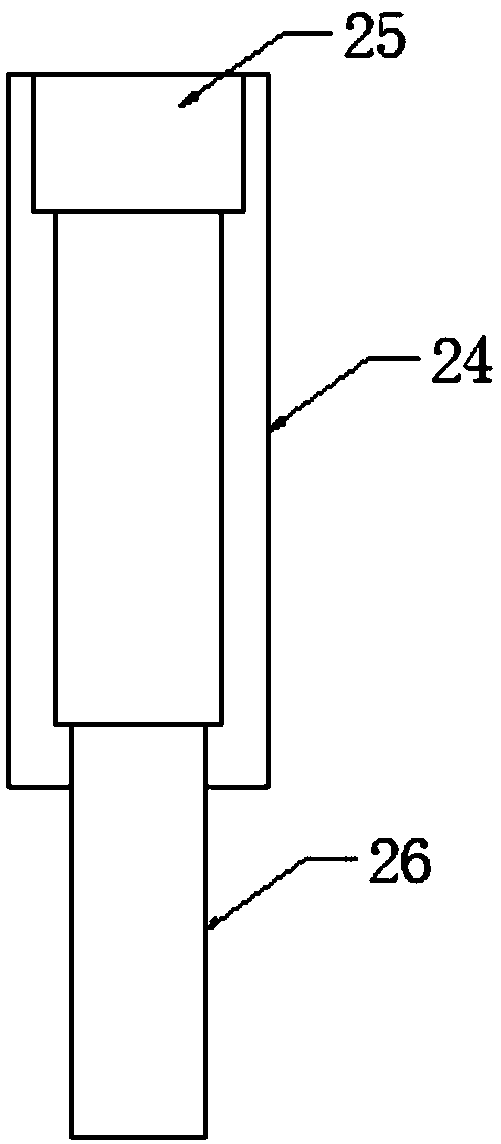

[0024] Such as Figure 1-5 As shown, an automatic clamping and feeding mechanical gripper includes a device body 1, and the device body 1 includes a table 2, and table legs 3 are fixedly installed at the four corners of the bottom of the table 2 and at both ends of the middle part. The bottoms of the table legs 3 are provided with support anti-slip mats 4, two connecting rods 5 are fixedly connected between the two shortest distances between the table legs 3, and the top end of the table 2 is fixedly installed with a first bearing plate 6 , the top of the first load-bearing plate 6 is provided with a first conveyor belt 7, the top of the first load-bearing plate 6 is provided with several vertical plates 8, and a top plate 9 is fixedly installed between the tops of two vertical plates 8, and the Both ends of the top plate 9 top are fixedly equipped with support blocks 10, the top of the support block 10 is fixedly equipped with support columns 11, and a second load-bearing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com