High-speed low-inclusion electroslag remelting device and remelting method thereof

A low-inclusion, electroslag remelting technology, applied in the low-inclusion electroslag remelting device, high-speed field, can solve the problems of accelerating consumable electrode smelting, the existence of inclusions, and low remelting efficiency, so as to reduce the Effects of energy consumption, improvement of purity, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

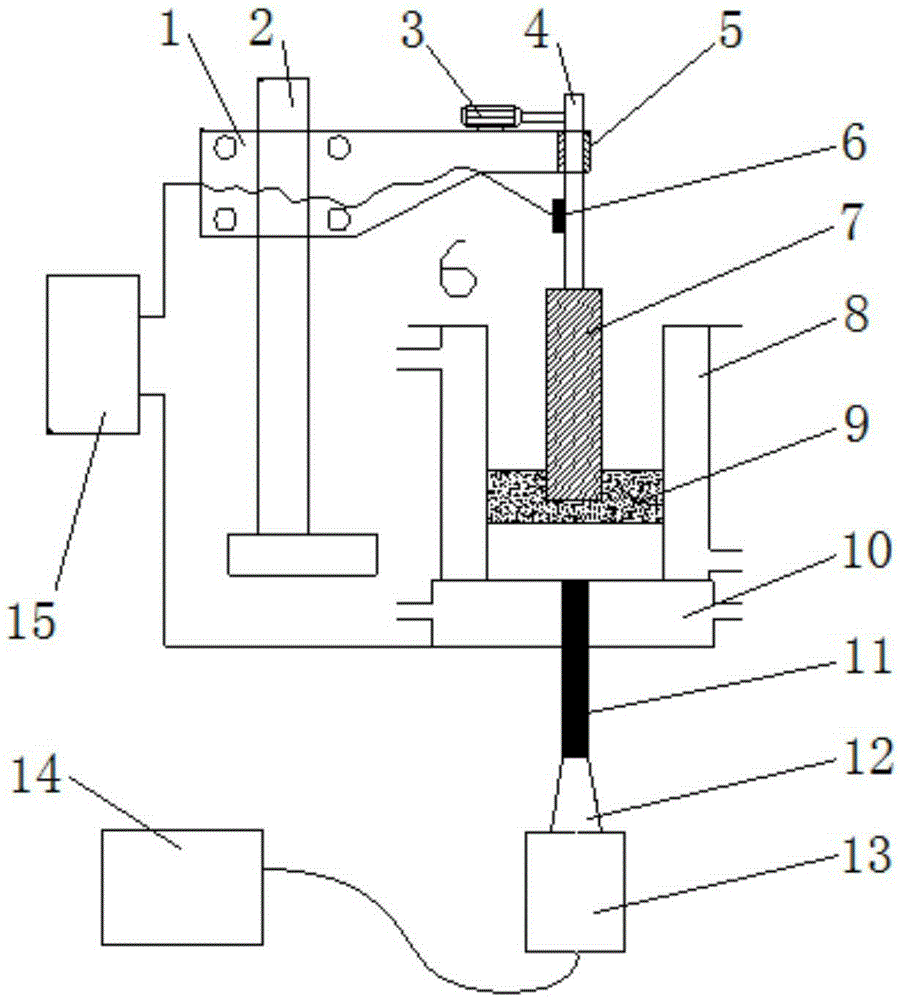

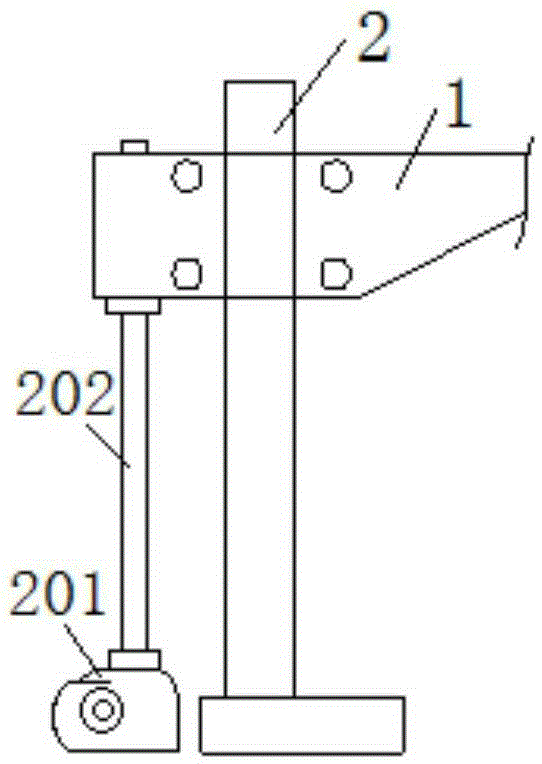

[0039] combine figure 1 , a high-speed, low-inclusion electroslag remelting device in this embodiment includes a transformer 15, a consumable electrode 7, a crystallizer 8, an electrode drive mechanism, and an ultrasonic generator installed at the bottom of the crystallizer 8. Among them, the electrode driving mechanism is mainly composed of a fixing device, a speed-regulating motor 3 and a dummy electrode 4. The dummy electrode 4 is made of cylindrical metal material. The axes of the consumable electrodes 7 coincide; the other end of the dummy electrode 4 is connected with the bearing 5 on the fixing device, so that the dummy electrode 4 can rotate in the bearing 5 . The upper section of the dummy electrode 4 protrudes from the upper side of the bearing 5, and is connected to the speed-regulating motor 3 installed on the fixture through the speed-reducing device, and the dummy electrode 4 is controlled to rotate by the speed-regulating motor 3 .

[0040]One end of the transf...

Embodiment 2

[0052] A high-speed, low-inclusion electroslag remelting method in this embodiment has the same basic steps as in Embodiment 1, the difference is that in this embodiment, the consumable electrode maintains a rotating speed of 20r / min, and the ultrasonic power Adjusted to 10W / cm 2 , Add Al-Mn-Si alloy to the slag pool for deoxidation, the addition amount is 5Kg / t steel.

Embodiment 3

[0054] A high-speed, low-inclusion electroslag remelting method in this embodiment has the same basic steps as in Embodiment 1, the difference is that in this embodiment, the consumable electrode maintains a rotating speed of 30r / min, and the ultrasonic power Adjusted to 5W / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com