Tie-dyeing method

A folding method and reactive dyeing technology, applied in the field of tie-dyeing, can solve the problems of many pinholes, affect the appearance of the cloth surface, and consume manpower, etc., and achieve the effect of strong flexibility, vivid and natural patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A tie-dyeing method, comprising the steps of:

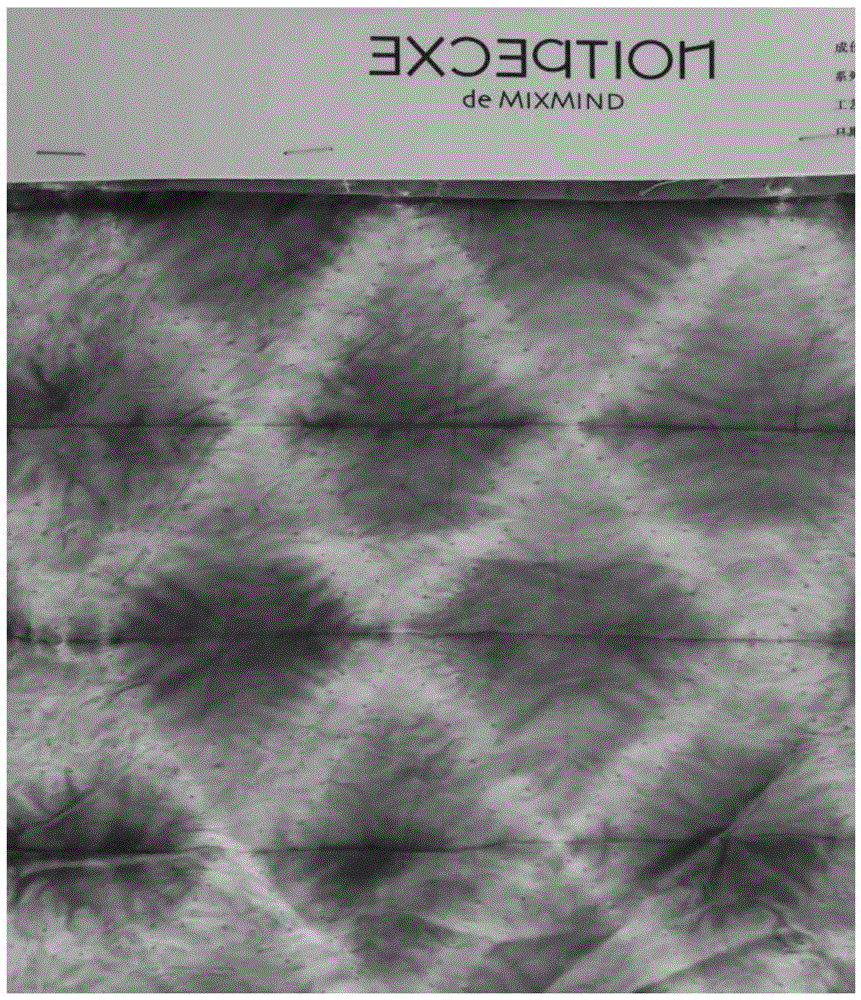

[0039] (1) Fold the fabric to be dyed into a long strip according to the parallel direction by adopting the screen folding method (see figure 2 ), the above screen folding method is to fold the cloth into screen pleats in parallel or diagonal directions;

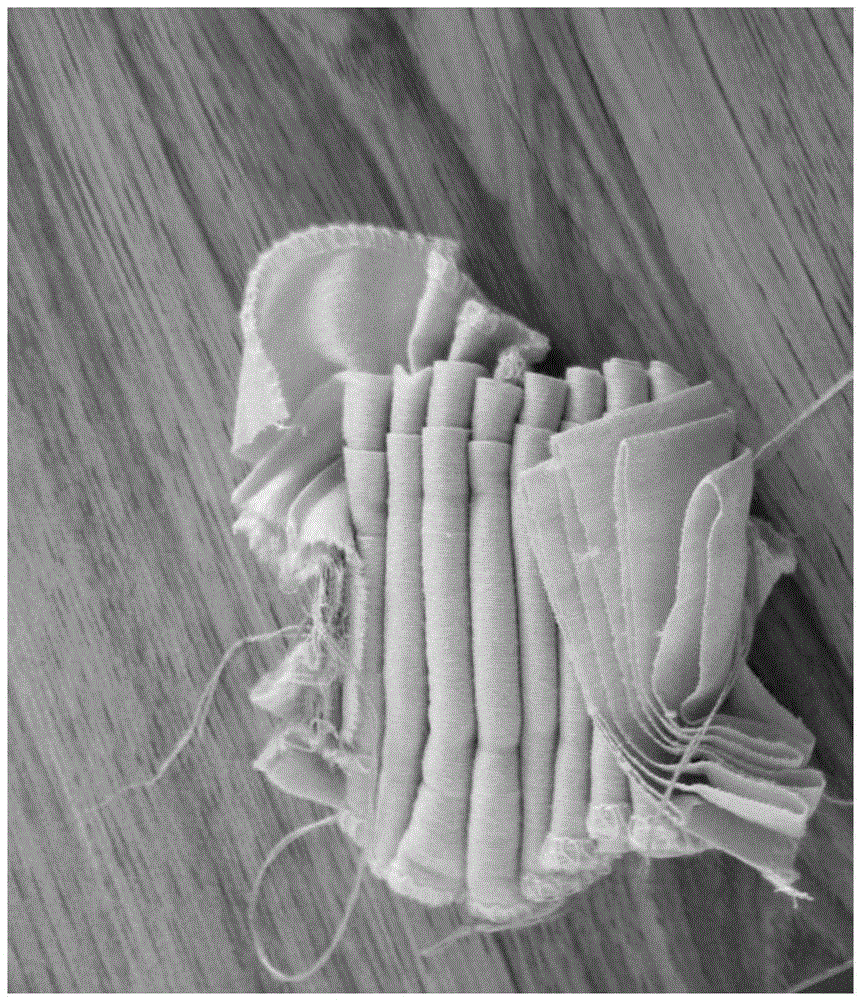

[0040] (2) Select the household bamboo mat block (dyeing part) of 2.5 * 1.3 * 0.3CM size for use, and the bamboo mat block is bundled on the fabric to be dyed after described step (1) folding at intervals and positioned (see image 3 ), get fabric 1;

[0041] (3) fabric 1 is placed in the dye vat, add medium temperature type reactive dyes (reactive red Remazol-Red3BS of DyStar company, active yellow Remazol-Yellow3RS and active blue Levafix-BlueCA), OWF value is 3%, heat up to 50 After warming for 10 minutes at ℃, slowly add 30g / l sodium sulfate to promote dyeing, raise the temperature to 65℃ and keep warm for 40 minutes, the bath ratio of the above active dyeing proc...

Embodiment 2

[0045] A tie-dyeing method, in its steps and raw materials, except that the amount of the following raw materials is different: the OWF value of reactive dyes is 4%, the amount of sodium sulfate is 50g / l, and the amount of soda ash is 20g / l. The addition amount of soaping agent once is 2g / l and the addition amount of soaping agent for the second time is 1g / l, all the other are the same as embodiment 1.

Embodiment 3

[0047] A tie-dyeing method, in its steps and raw materials, except that the amount of the following raw materials is different: the OWF value of reactive dyes is 3.5%, the amount of sodium sulfate is 40g / l, and the amount of soda ash is 18g / l. The addition amount of soaping agent for the first time is 1.5g / l and the addition amount of soaping agent for the second time is 0.8g / l, all the other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com