A kind of preparation method of anti-ultraviolet and far-infrared ecological fabric

A far-infrared and anti-ultraviolet technology, which is applied in the fields of enzyme/microbial biochemical treatment, rayon manufacturing, biochemical fiber treatment, etc., can solve problems such as high cost and physical impact, and achieve high cost, pollution reduction, economic benefits and social benefits. The effect of limited benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

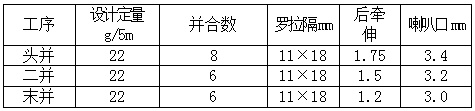

Embodiment 1

[0036] A method for preparing an anti-ultraviolet and far-infrared ecological fabric, the method comprising the following steps: 1) selection and matching of raw materials; since pre-spinning coloring has no special requirements for yarn spinning, the original spinning equipment and production technology can be used . Especially when polyester fiber is blended with other fibers, the use of colored polyester fiber not only reduces the dyeing process, but also facilitates the realization of the pre-designed style of the fabric. And pre-spinning coloring reduces the dyeing process of printing and dyeing equipment and multi-channel fibers or fabrics, removes dyeing auxiliaries, combines every pigment molecule into the target product, fundamentally eliminates the discharge of dyes, and reduces the consumption of raw materials , to avoid environmental pollution, reduce dyeing costs, and save huge pollution control costs. What we use is pre-spinning coloring. Before spinning, the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com