Printing production method

A production method and printing technology, applied in printing, copying/marking methods, printing devices, etc., can solve the problems of single printing process, no deep visual sense, plain decoration effect, etc., and achieve high resolution and pattern Fine, pattern changing and more aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below.

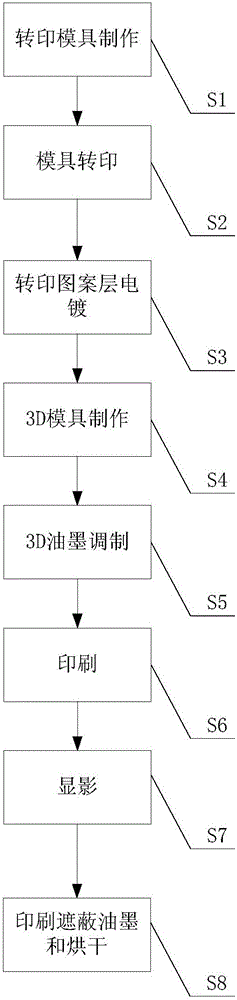

[0021] see figure 1 , the printing production method of the present invention comprises the following steps:

[0022] S1, transfer mold making: the designed pattern is made on the mold, and the transfer mold is made into a roller type or a flat plate type.

[0023] S2, use the transfer machine to transfer the mold to the printing material: apply the UV glue on the substrate (the printing material), imprint it with the transfer mold, and then use the UV light curing lamp on the transfer machine for light curing. Among them, the printing materials include PC, PET, PMMA, PC+PMMA composite board, explosion-proof film, physical toughened glass, chemical toughened optical glass and other transparent materials.

[0024] S3, electroplating the transfer pattern layer of the printed matter to protect and isolate.

[0025] S4, 3D mold making: Determine the size of the mold base material according to the required pattern s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com