Method for making productí»s pattern

A production method and product technology, applied in the direction of layered products, chemical instruments and methods, and processes for producing decorative surface effects, etc., can solve the problems of insufficient refinement, fidelity, and complicated processes, and achieve exquisite and realistic patterns and simplified production. Durable and wear-resistant effect of process and pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

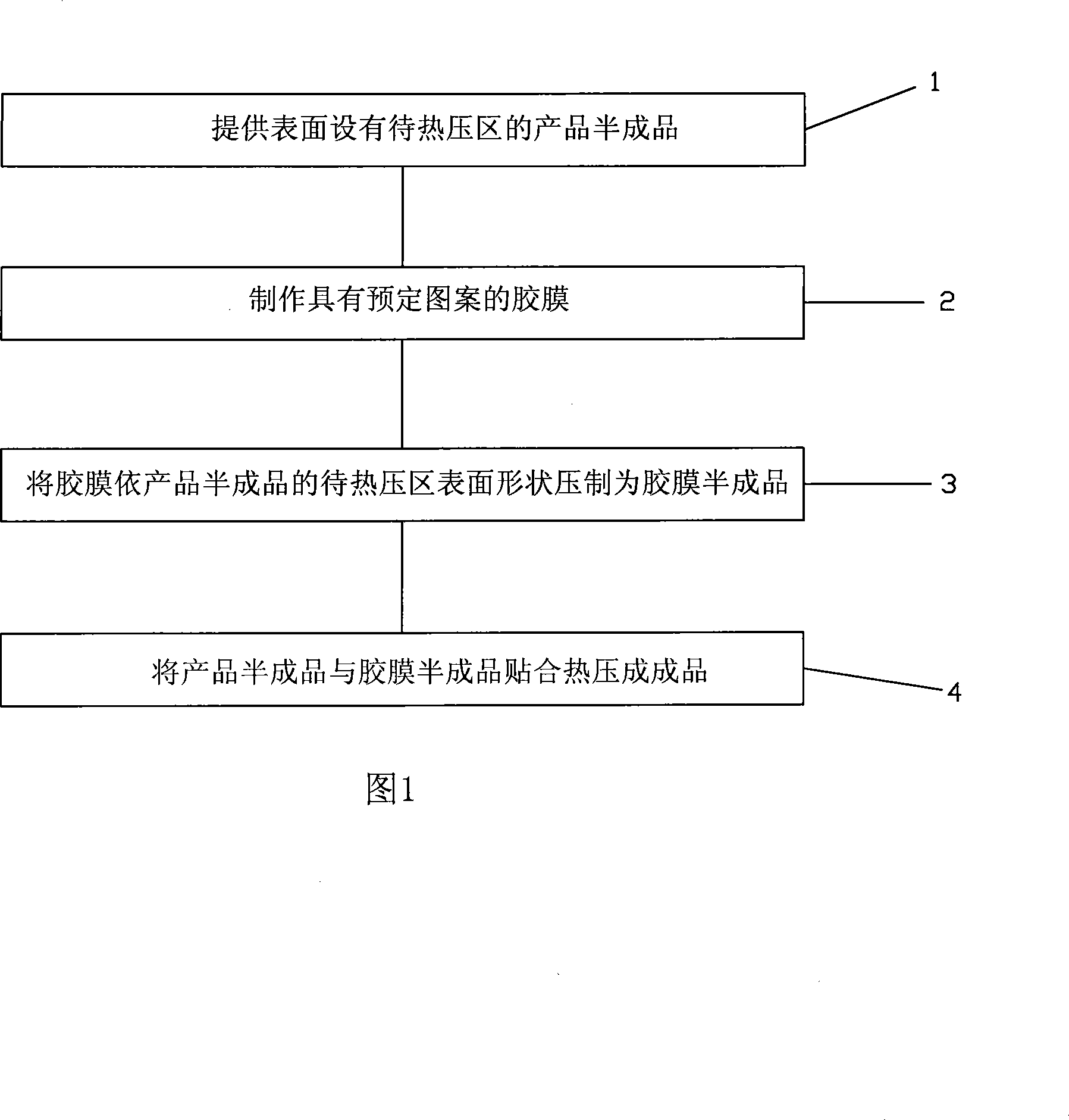

[0013] Referring to FIG. 1 , it is a flowchart of a method for making a product pattern of the present invention. The method includes the following steps:

[0014] Step 1: Provide a semi-finished product with a surface to be hot-pressed;

[0015] The semi-finished product is made of resin such as PVC / PP / PC for injection molding, and the surface of the semi-finished product is provided with a hot-pressing area. The hot-pressing area can be the entire surface of the semi-finished product, or it can be a part.

[0016] Step 2: making an adhesive film with a predetermined pattern;

[0017] In this step, the manufacturing step of the adhesive film includes: providing a base film; printing a pattern layer on a surface of the base film with high temperature resistant ink; and printing a base color layer on the pattern layer.

[0018] The material of the bottom film can be PVC / PP / PC, etc., which is different from the semi-finished product, and then made into a bottom film of suitabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com