Constant-temperature hot sublimation color development machine

A coloring machine, warm technology, applied in printing, printing device and other directions, can solve the problems of unclear product pattern, easy deformation, large color difference on both sides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

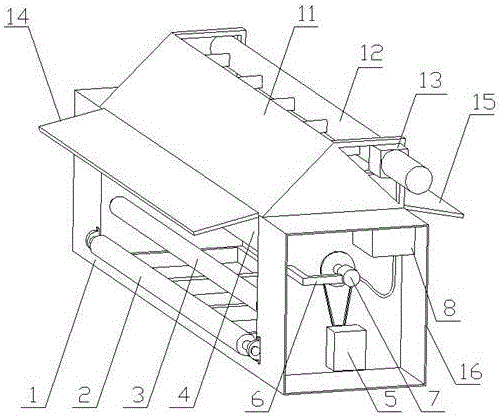

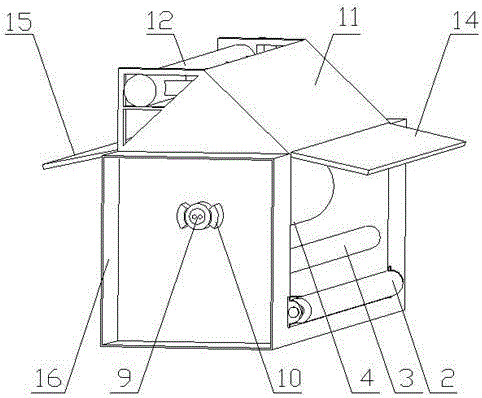

[0011] like Figure 1-2 As shown, the present invention includes: a frame 1, an open cloth release roller 2, a cloth receiving transmission roller 3, an oil-electric heating roller 4, a reduction motor 5, a bracket 6, a rotary joint 7, an oil tank 8, an electric heater 9, an electric The brush device 10, the smoke collecting hood 11, the smoke exhaust pipe 12, the fan 13, the front cover 14 and the rear cover 15; The roller shaft of the oil-electric heating roller 4 is installed in the middle of the frame 1 through a bearing seat. The oil-electric heating roller 4 is hollow and filled with heat-conducting oil. The gear is in transmission connection with the oil-electric heating roller 4, the bracket 6 is installed on the frame 1, the rotary joint 7 is installed on the right side of the oil-electric heating roller 4 and fixed by the bracket 6, and the oil tank 8 is connected with the rotary joint 7 through an oil pipe. The electric heater 9 is installed on the left side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com