Method for preparing C-doped alpha-Al2O3 transparent ceramic thermoluminescent and photoluminescent material

A technology of transparent ceramics and doped materials, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of difficult preparation of large size, limited amount of carbon doping, high cost, etc., to achieve industrial scale production and preparation process Simple, low-cost-to-manufacture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

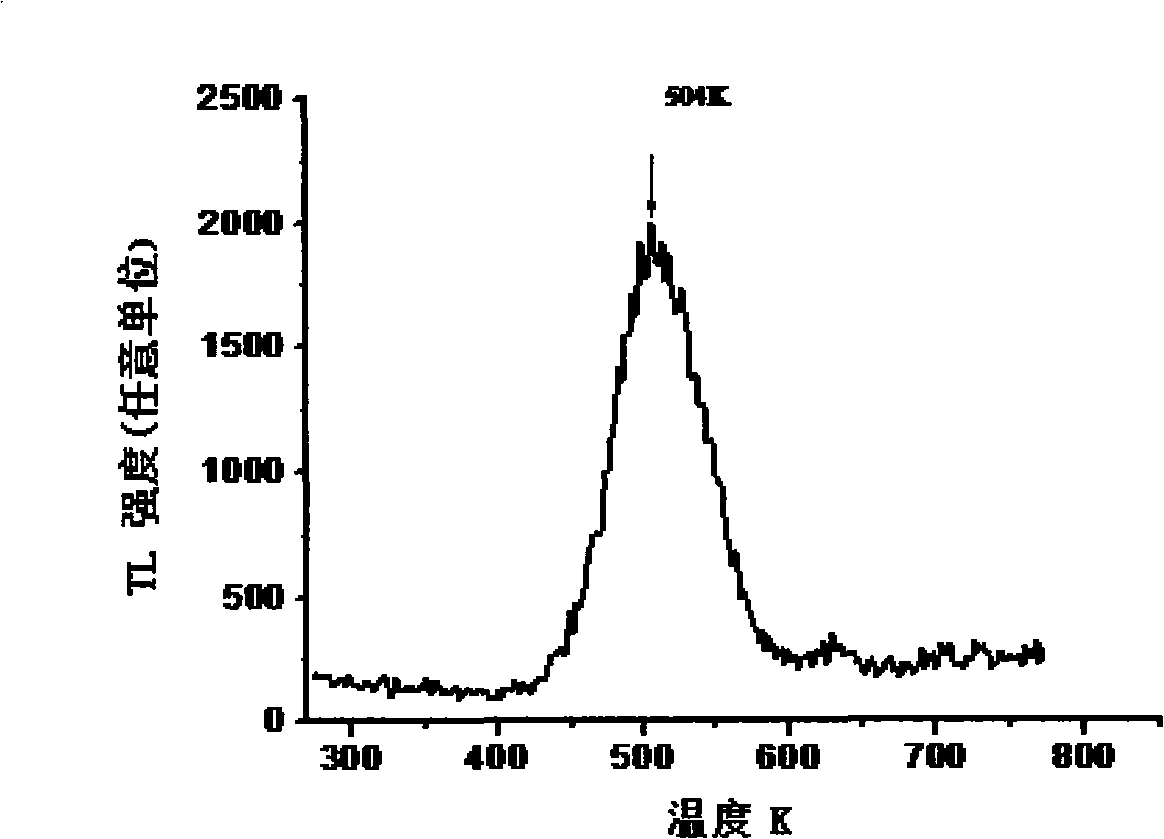

Image

Examples

Embodiment 1

[0027] The preparation process of this embodiment adopts two processes including transparent ceramic sintering process and carburizing process.

[0028] The process and steps of the present embodiment are described as follows:

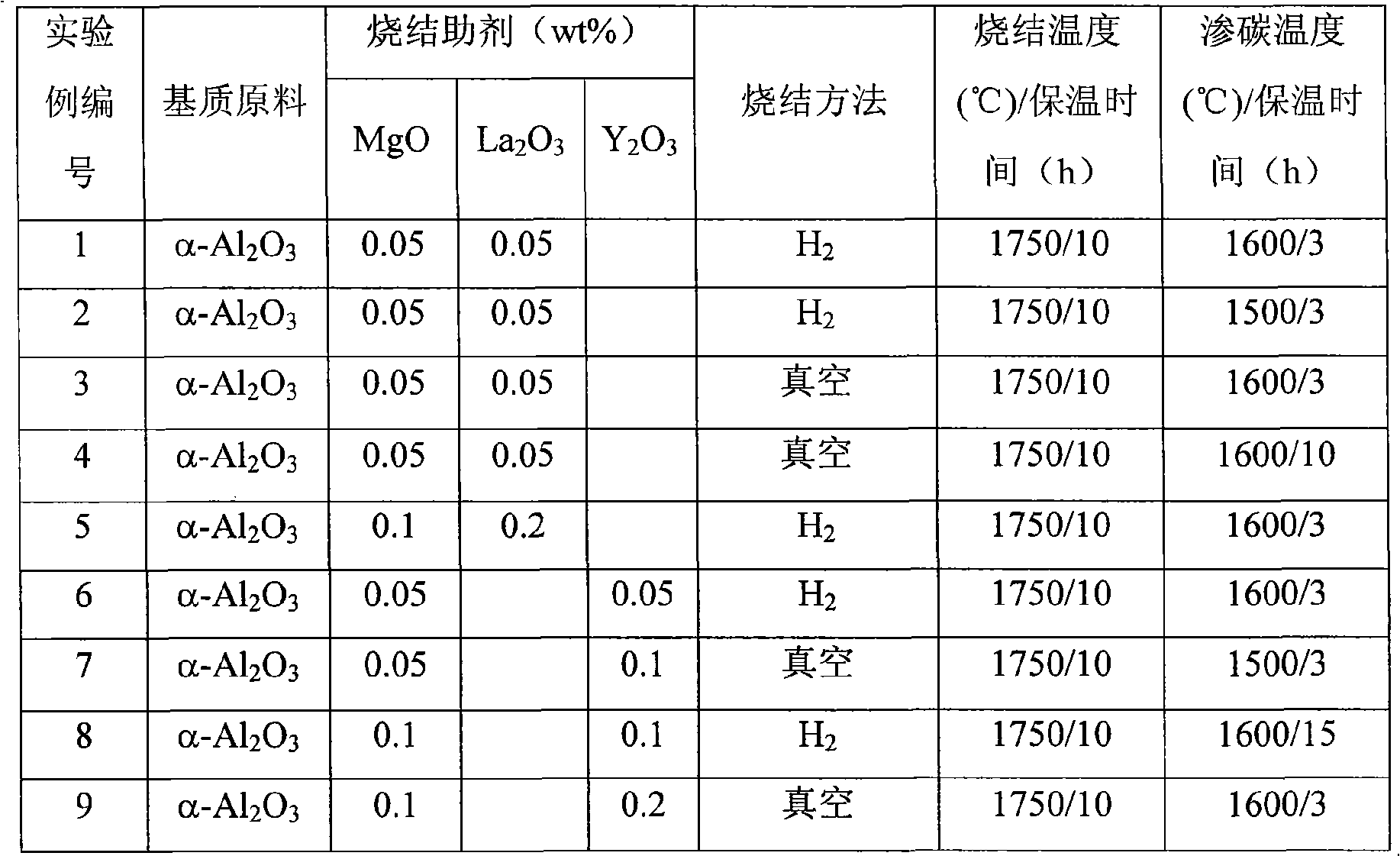

[0029] 1. α-Al 2 o 3 Preparation of transparent ceramics

[0030] a. Using high-purity 99.99% Al 2 o 3 , 99% MgO, 99.99% La 2 o 3 or Y 2 o 3 As raw material, with Al 2 o 3 as matrix material, MgO, La 2 o 3 or Y 2 o 3 As a sintering aid; with Al 2 o 3 The weight of the base material is 100 as the measurement basis, and the doping amount of the doping material is: La 2 o 3 or Y 2 o 3 : 0.05~0.20wt%; MgO: 0.05~0.2wt%;

[0031] b. Al prepared according to the above formula 2 o 3 Stir and mix the base material and each dopant material, and mix and grind the mixture in distilled water for 24 hours;

[0032] c. drying at a temperature of 150°C, then adding a polyvinyl alcohol binder with a concentration of 5wt%, and the addition amount ...

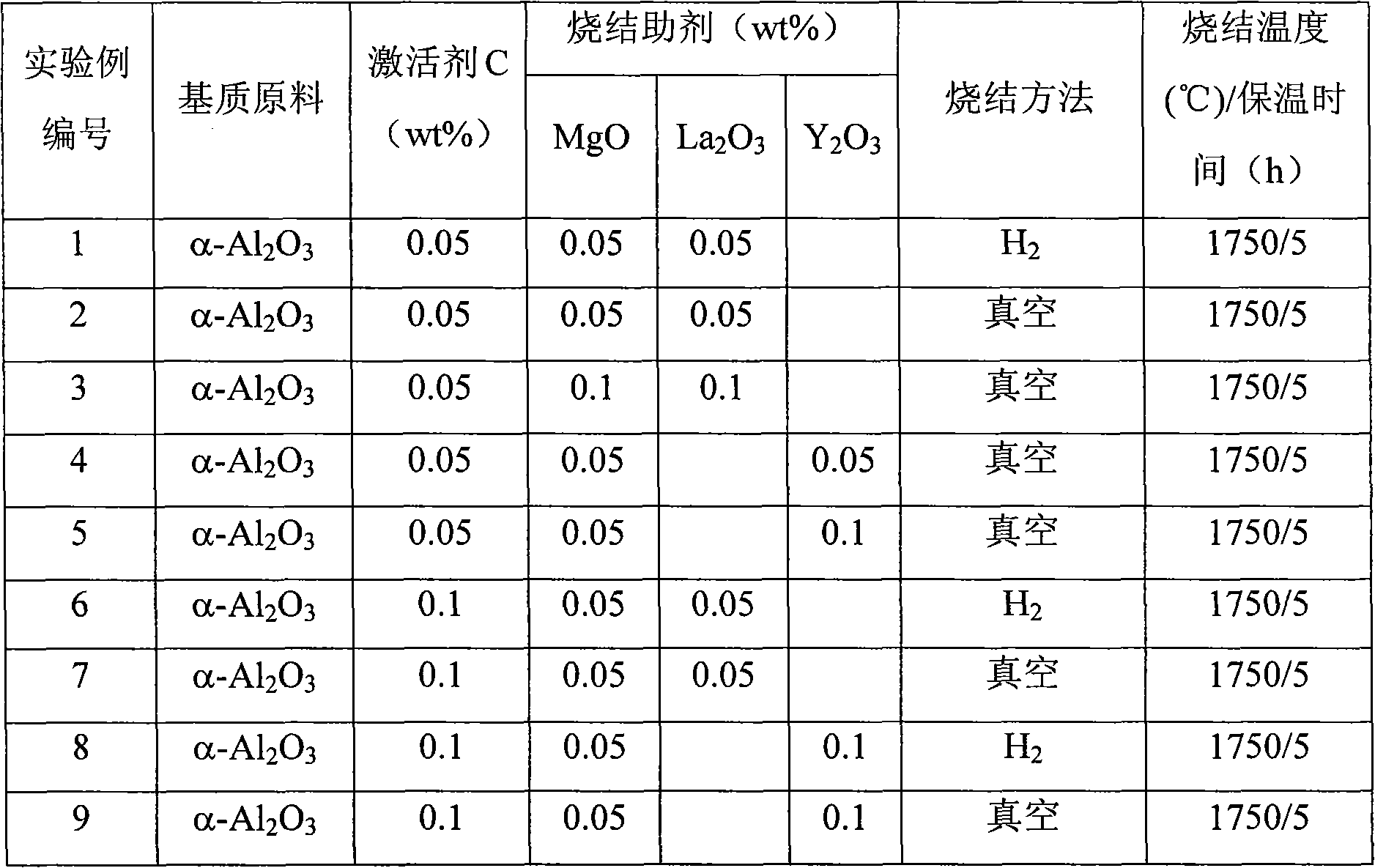

Embodiment 2

[0041] The process and steps of the present embodiment are described as follows:

[0042] a. Using high-purity 99.99% Al 2 o 3 , high-purity graphite powder, 99% MgO and 99.99% La 2 o 3 or Y 2 o 3 as raw material; with Al 2 o 3 As the matrix material, C, MgO and La 2 o 3 or Y 2 o 3 as doping material; with Al 2 o 3 The weight of the base material is 100 as a measurement basis, where MgO and La 2 o 3 or Y 2 o 3 It is a sintering aid, and C is a thermoluminescent and photoluminescent activator. The doping amount of MgO is 0.05-0.2wt%, La 2 o 3 or Y 2 o 3 The doping amount of C is 0.05-0.2wt%; the doping amount of C is 0.05-0.2wt%;

[0043] b. Al prepared according to the above formula 2 o 3 Stir and mix the base material and each dopant material, and mix and grind the mixture in distilled water for 24 hours;

[0044] c. drying at a temperature of 150°C, then adding a polyvinyl alcohol binder with a concentration of 5wt%, and the addition amount is 5% of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com